Burner and flame temperature control method

A flame temperature and burner technology, applied in the burner control device, combustion method, burner and other directions, can solve the problem of high temperature of the flame ejected from the burner, avoid overheating and melting, reduce the difficulty of operation and the effect of scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

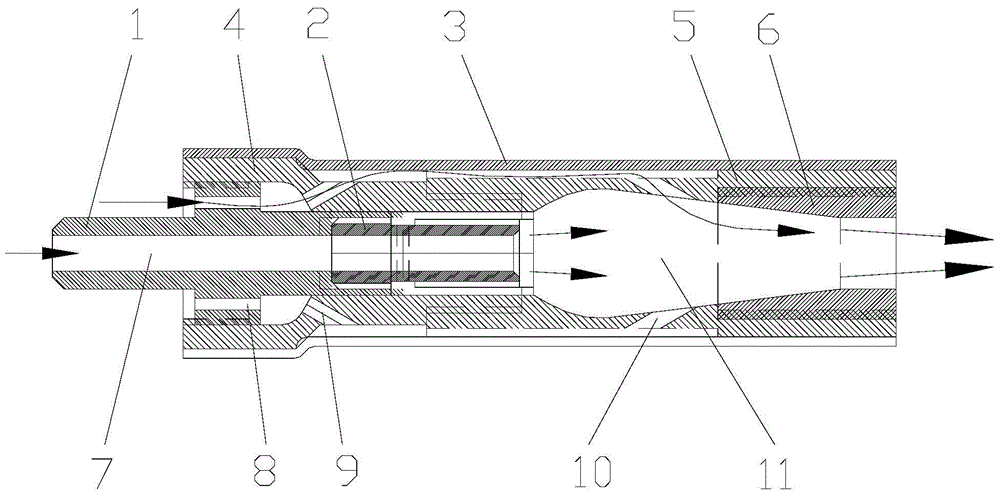

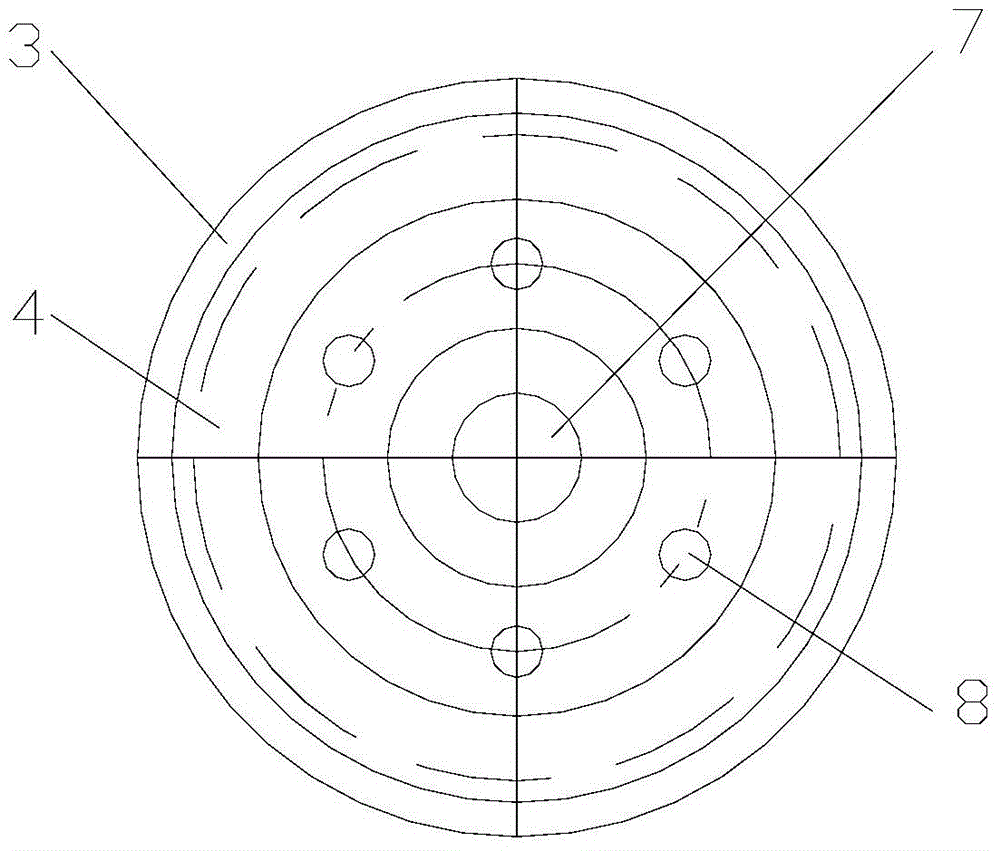

[0027] Such as figure 1 As shown, the embodiment of the present invention provides a burner, which includes a flow divider 1, a burner 2 and a casing 3, and the flow divider 1 is provided with a gas through hole 7 and at least one cold air flow hole 8 , one end of the flow divider 1 is arranged outside the housing to communicate with the gas pipeline, the other end of the flow divider 1 and the burner 2 are both arranged inside the shell 3, and the flow divider 1 and the The interior of the burner 2 is connected, and the gas enters the gas through hole 7 from the gas pipeline, enters the burner 2 through the gas through hole 7, and burns in the shell 3 after being ignited by the burner 2 to form Flame air flow, the cold air flow enters the interior of the casing 3 from the cold air flow hole 8, and is outside the gas passage 7 and the burner 2, and passes between the flow divider 1 and the casing 3 The gap between the burner 2 and the shell 3 is mixed with the flame air flow ...

Embodiment 2

[0036] An embodiment of the present invention provides a flame temperature control method, the method comprising: passing gas into the gas through hole of the flow divider, the gas enters the gas through hole and ignites and burns through the burner to form a flame flow, and the cold gas The cold air flows into the cold air flow hole of the flow divider, and the cold air flow enters the interior of the shell through the cold air flow hole and mixes with the flame air flow to reduce the temperature of the flame air flow to form a low temperature flame air flow.

[0037] As a preference, the cold airflow adopts a mixed gas of air and nitrogen. When the cold airflow is mixed with the flame airflow, the oxygen in the air can play a certain combustion-supporting effect on the combustion of the gas. Since the cold airflow contains inert gas, it ensures The shape of the flame also plays a protective role, reducing the oxygen content in the environment and reducing the oxidation of the...

Embodiment 3

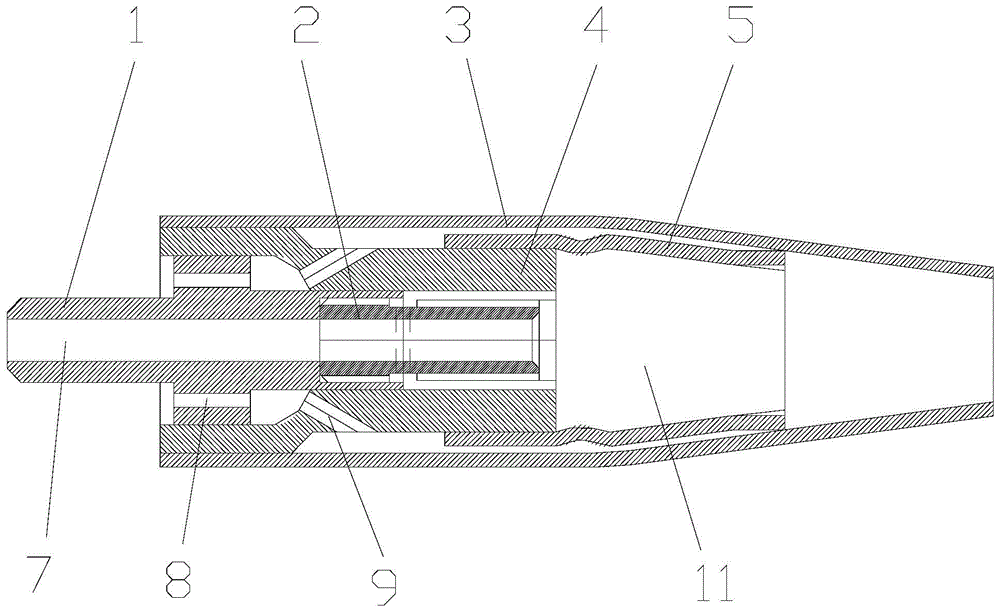

[0041] Such as image 3 As shown, the embodiment of the present invention provides a burner, the outlet nozzle 6 of the burner and the shell 3 are designed as an integral structure, that is, the shell 3 is designed to be a structure with a smaller diameter along the direction in which the flame flow is ejected, reducing The outlet nozzle 6 is eliminated, so that the structure of the burner is simpler and the processing cost is lower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com