Matching sample frame ball positioning and connecting device

A ball positioning and connecting device technology, which is applied to the connection between large frames of matching sample racks and inspection tools, and the field of matching sample rack ball positioning connecting devices, can solve the problems of cumbersome operation, poor connection reliability, complex structure, etc., to meet the positioning requirements. and connection problems, reliable function, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

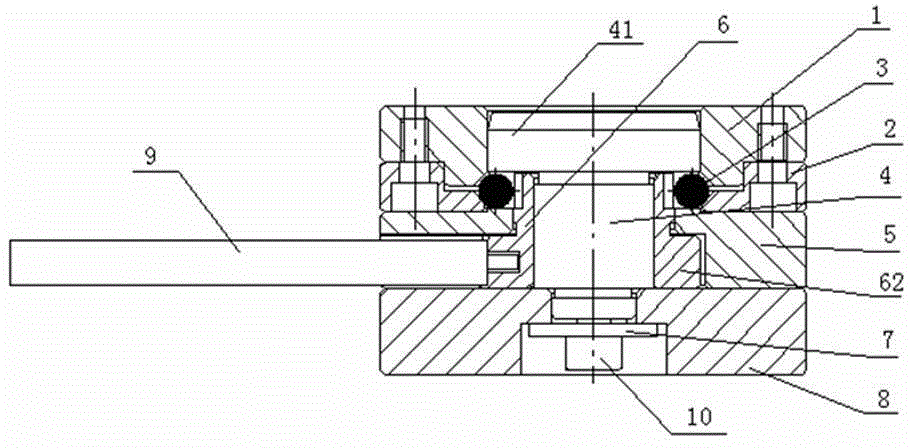

[0012] see Figure 1 ~ Figure 4 , a matching sample rack ball positioning connection device of the present invention is characterized in that the device is composed of an A component and a B component, the A component includes a positioning ring 1 and a connecting ring 2, and the two are coaxially overlapped and connected together. The ring 2 (or the junction of the two inner peripheral surfaces) is provided with an annular groove 11 . The positioning ring 1 and the connecting ring 2 are connected to each other through a plurality of axial screws.

[0013] The B assembly includes a ball 3, a positioning pin 4, a ball snap ring 5, a bushing 6, a support 8 and a handle 9, and a ball snap ring 5 is coaxially arranged on the annular support 8, and the ball snap ring 5 An upper flange 51 is provided on the top end of the upper flange 51, and several ball notches 52 corresponding to the annular groove 11 are arranged on the upper flange 51 evenly distributed along the circumference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com