Pier-extruded and half-grouted steel bar sleeve, connecting structure and construction method

A technology for steel sleeves and connecting structures, which is applied to structural elements, building components, building structures, etc., can solve the problems of low processing efficiency and complex process of grouting sleeves, and achieves guaranteeing construction efficiency and construction quality. Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

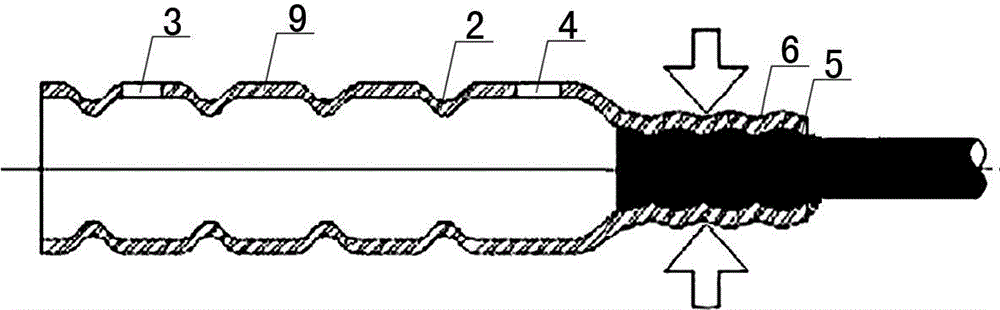

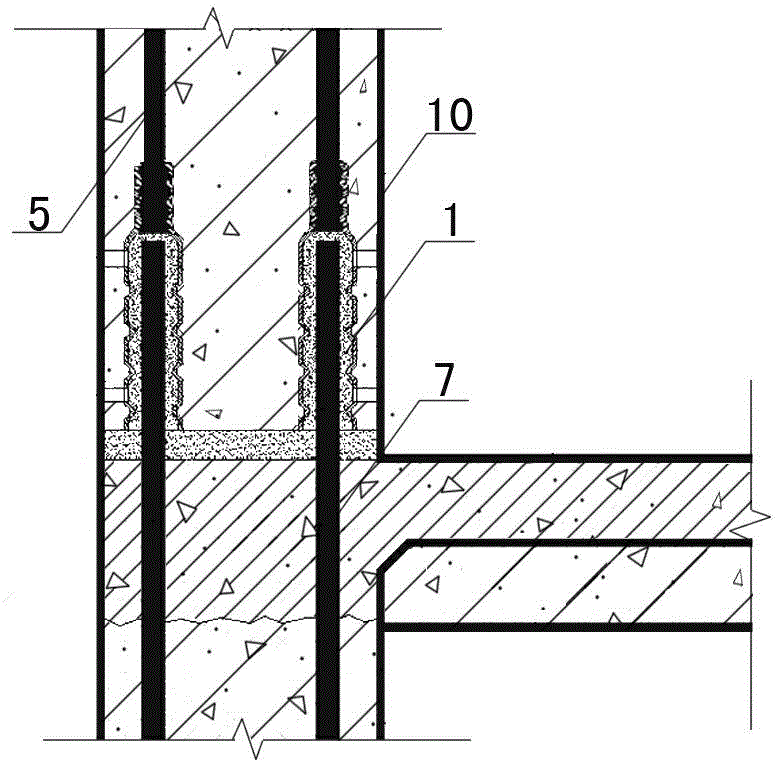

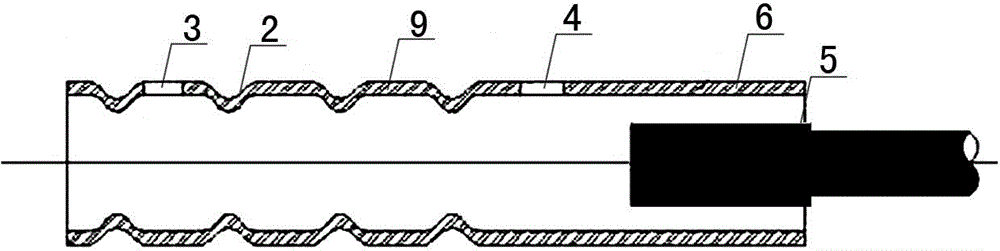

[0042] Examples see image 3 As shown, the pier head extrudes the semi-grouting reinforcement sleeve, the sleeve 1 is processed by hot-rolled seamless steel pipe, and the wall of the sleeve is provided with a grouting hole 3 and a grouting hole 4, and Annular inner protrusions 2 are distributed between the grouting hole 3 and the grouting hole 4. The annular inner protrusions 2 are single rings evenly spaced and can be processed by three-axis rolling, rolling or other cold and hot processing techniques. , one end of the sleeve 1 is the extruded end 6, and the rest is the slurry anchor end 9, the inner diameter of the extruded end 6 is equal to the outer diameter of the connected steel bar and smaller than the inner diameter of the slurry anchor end 9, the extruded end 6 The length of the pressure end 6 meets the requirements of the strength of the extrusion joint, and the length of the grout anchor end 9 meets the requirements of the strength of the steel grouting sleeve conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com