Linear evaporation source

A linear evaporation source and steam technology, applied in the field of evaporation sources, can solve the problems of limited space for equalizing pressure, large influence of evaporation film thickness uniformity, limited space for steam mixing and homogenization, etc., to achieve good uniformity and simplify heating methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate a further understanding of the structure and achieved effects of the present invention, preferred embodiments are described in detail below in conjunction with the accompanying drawings.

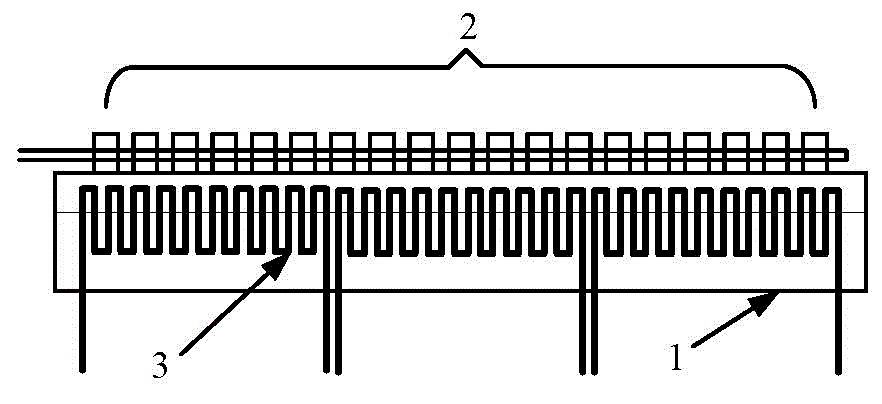

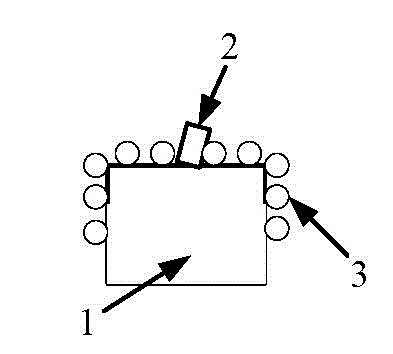

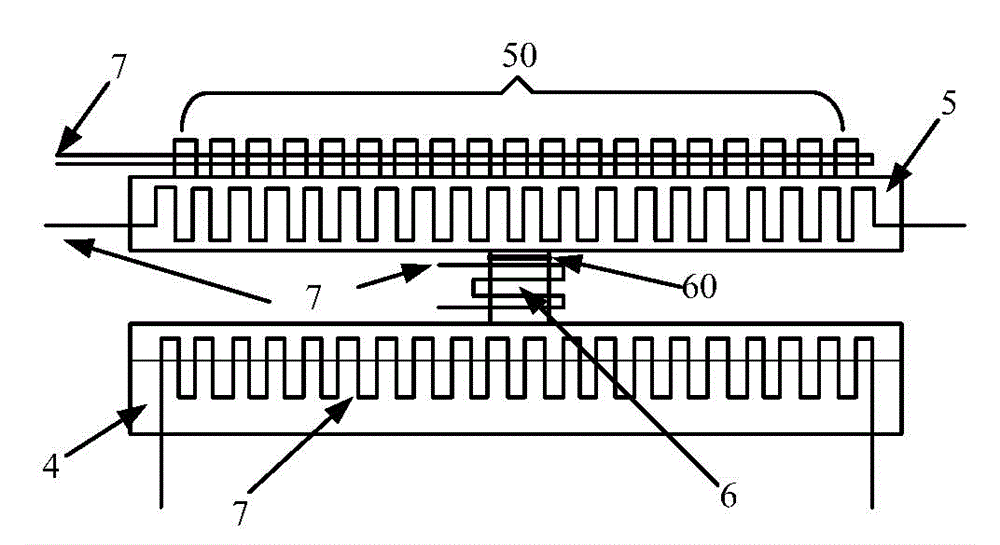

[0024] Such as image 3 and Figure 4 As shown, the linear evaporation source of the present invention includes a heating chamber 4, a mixing chamber 5 located above the heating chamber 4, and a passage 6 for connecting the heating chamber 4 and the mixing chamber 5. One end of the mixing chamber 5 and the heating chamber 4 pass through the passage 6 Conduction, the other end is provided with a plurality of nozzles 50, the heating chamber 4, the mixing chamber 5, the channel 6 and the periphery of the nozzles 50 are respectively provided with heaters 7.

[0025] When the linear evaporation source of the present invention performs evaporation on the substrate, the evaporation material is placed in the heating chamber 4, and the heating chamber 4, the mixing cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com