A kind of q345 grade anti-seismic steel and the method for producing q345 grade anti-seismic steel with a steel coil mill

A technology of steckel rolling mill and anti-seismic steel, which is applied in the field of metal material processing and forming, can solve the problems of low yield ratio and high strength, achieve low yield ratio, improve strength and toughness, and achieve significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

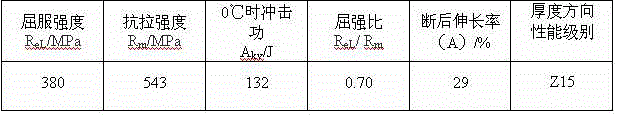

Image

Examples

Embodiment 1

[0024] The Q345 anti-seismic steel, the percentage composition of the Q345 anti-seismic steel is: C0.16wt%, Si0.46wt%, Mn1.35wt%, S0.030wt%, P0.032wt%, Nb0.035wt%, V0.02wt% %, Ti0.02wt%, N0.007wt%, Als0.015wt%, and the rest are Fe and other impurities, which are unavoidable impurities.

[0025] The method for producing Q345 grade shock-resistant steel with this steckel mill: firstly, after heating the slab and spraying water to remove phosphorus, the rough rolling and finish rolling are continuously completed on the same double-stand compact steck The steel plate is sent to the coiler to be coiled, and then naturally air-cooled to room temperature, and the Q345 seismic steel plate with high strength and low yield ratio is obtained.

[0026] Specific steps are as follows:

[0027] Step 1. First, heat the slab at 1230°C for 170 minutes, and control the time of the slab in the soaking section to 50 minutes to ensure that the micro-alloys such as Nb and V precipitated in the slab...

Embodiment 2

[0037] The Q345 anti-seismic steel, the percentage components of the Q345 anti-seismic steel are: C0.08wt%, Si0.50wt%, Mn1.70wt%, S0.025wt%, P0.028wt%, Nb0.030wt%, V0.03wt% %, Ti0.03wt%, N0.009wt%, Als0.028wt%, the rest is Fe and unavoidable impurities.

[0038] The method for producing Q345 grade shock-resistant steel with this steckel mill: firstly, after heating the slab and spraying water to remove phosphorus, the rough rolling and finish rolling are continuously completed on the same double-stand compact steck The steel plate is sent to the coiler to be coiled, and then naturally air-cooled to room temperature, and the Q345 seismic steel plate with high strength and low yield ratio is obtained.

[0039] Specific steps are as follows:

[0040] Step 1. First, heat the slab for 190 minutes at a temperature of 1240° C., and control the time of the slab in the soaking section to 60 minutes to ensure that the micro-alloys such as Nb and V precipitated in the slab are fully re-...

Embodiment 3

[0050] The Q345 anti-seismic steel, the percentage composition of the Q345 anti-seismic steel is: C0.13wt%, Si0.35wt%, Mn1.55wt%, S0.032wt%, P0.025wt%, Nb0.030wt%, V0.04wt% %, Ti0.05wt%, N0.010wt%, Als0.015wt%, the rest is Fe and unavoidable impurities.

[0051] The method for producing Q345 grade shock-resistant steel with this steckel mill: firstly, after heating the slab and spraying water to remove phosphorus, the rough rolling and finish rolling are continuously completed on the same double-stand compact steck The steel plate is sent to the coiler to be coiled, and then naturally air-cooled to room temperature, and the Q345 seismic steel plate with high strength and low yield ratio is obtained.

[0052] Specific steps are as follows:

[0053] Step 1. First, heat the slab at a temperature of 1210°C for 150 minutes, and the time of the slab in the soaking section is controlled at 50 minutes to ensure that the micro-alloys such as Nb and V precipitated in the slab are fully...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com