A steel pipe quenching device

A quenching device and steel pipe technology, which is applied in the direction of quenching devices, furnaces, heat treatment equipment, etc., can solve the problems of restricting quenching quality, achieve the effects of improving quenching quality, increasing turbulence intensity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

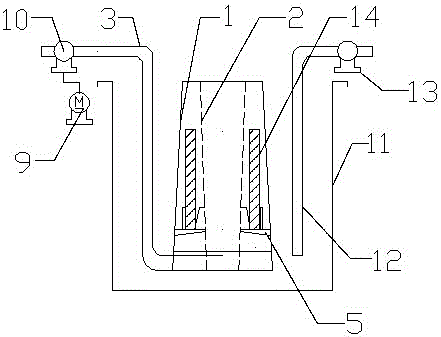

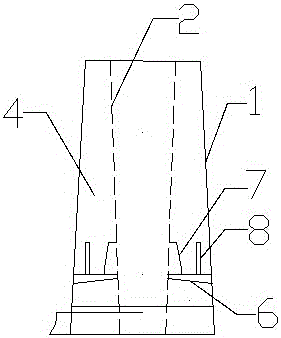

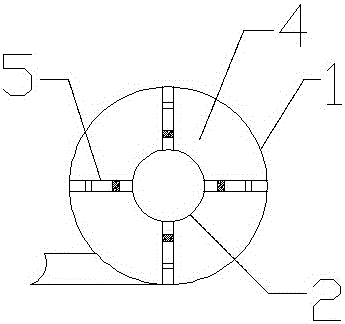

[0017] Such as figure 1 , figure 2 and image 3 As shown, a steel pipe quenching device includes a conical shrinking outer cylinder 1, a conical expanding inner cylinder 2 and a high-pressure water supply pipeline 3. The conical shrinking outer cylinder 1 is a frustum-shaped cylinder with a small upper end and a larger lower end. The inner cylinder 2 is a truncated cone-shaped cylinder with a large upper end and a smaller lower end. The conical expanding inner cylinder 2 is fixedly arranged in the conical shrinking outer cylinder 1, and the conical expanding inner cylinder 2 and the conical shrinking outer cylinder 1 are arranged coaxially. The outer surface of the tapered expansion inner cylinder 2 and the inner surface of the conical contraction outer cylinder 1 form a cavity 4 with an upper end opening. The cross-sectional area of the cavity 4 gradually decreases from bottom to top. The high-pressure water supply pipeline 3 communicates with the bottom of the cavity 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com