A kind of weak gelling agent for drilling fluid and preparation method thereof

A technology of weak gelling agent and drilling fluid, which is applied in the field of weak gelling agent for drilling fluid and its preparation, which can solve the problems of static suspended sand and dynamic sand-carrying that cannot be solved well, lift cutting and resist temperature difference, resist Problems such as poor temperature effect, to solve the problem of static suspended sand and dynamic sand carrying, good viscosity increase and cutting, and improve the effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

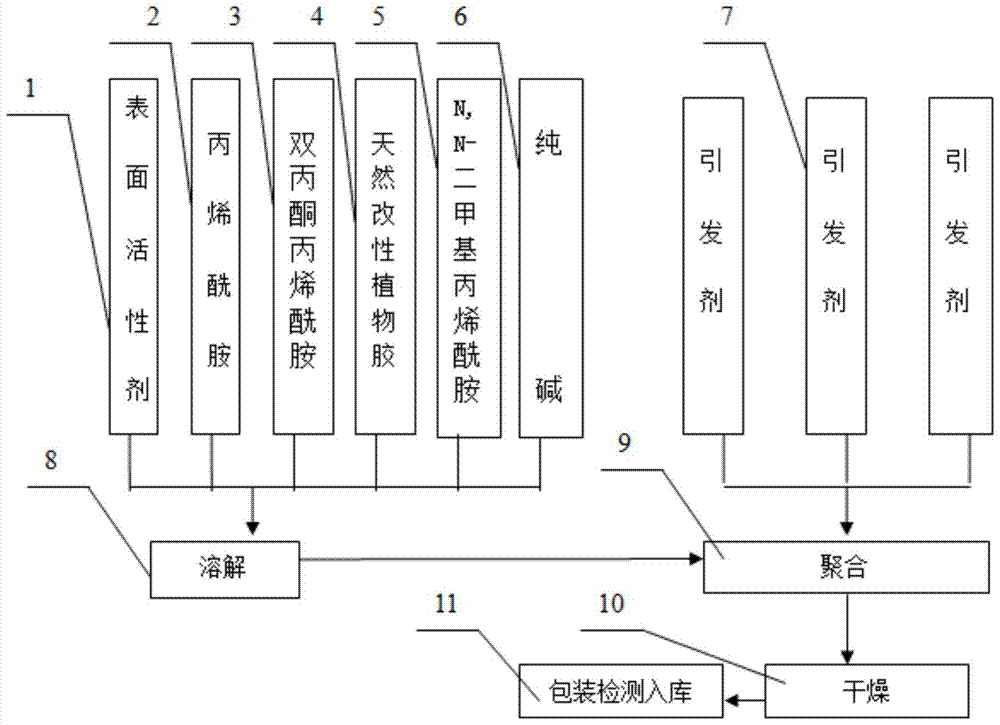

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Under normal temperature conditions, add 100 parts of clear water to the reactor, turn on the stirring, and then slowly add 30 parts of modified konjac vegetable gum, 3 parts of surfactant, 10 parts of N,N-dimethylacrylamide, 27 parts of acrylamide, 13 parts of diacetone acrylamide, 15 parts of soda ash, adjust the pH value to 8.5, stir for 30-60 minutes, blow nitrogen to remove oxygen for 20-40 minutes, when the temperature of the reaction kettle is around 20°C, add them in sequence 1 part of photoinitiator, 0.5 part of EDTA and 0.5 part of chain transfer agent, the above-mentioned reactants are all added according to the aforementioned ratio; this polymerization is an exothermic reaction, with the addition of the three initiators, the temperature of the material will rise slowly. When it rises to the highest point and stops rising (1-2 hours), keep the temperature constant and polymerize for 6-8 hours under the irradiation of ultraviolet rays, then granulate...

Embodiment 2

[0017] Example 2: Under normal temperature conditions, add 100 parts of clear water to the reactor, turn on the stirring, and then slowly add 35 parts of modified konjac vegetable gum, 4 parts of surfactant, 10 parts of N,N-dimethylacrylamide, 20 parts of acrylamide, 14 parts of diacetone acrylamide, 15 parts of soda ash, adjust the pH value to 8.5, stir for 30-60 minutes, blow nitrogen to remove oxygen for 20-40 minutes, when the temperature of the reaction kettle is around 20°C, add them in sequence 1 part of photoinitiator, 0.5 part of EDTA and 0.5 part of chain transfer agent, the above-mentioned reactants are all added according to the aforementioned ratio; this polymerization is an exothermic reaction, with the addition of the three initiators, the temperature of the material will rise slowly. When it rises to the highest point and stops rising (1-2 hours), keep the temperature constant and polymerize for 6-8 hours under the irradiation of ultraviolet rays, then granulate...

Embodiment 3

[0018] Example 3: Under normal temperature conditions, add 100 parts of clear water to the reactor, turn on the stirring, and then slowly add 35 parts of modified konjac vegetable gum, 3 parts of surfactant, 10 parts of N,N-dimethylacrylamide, 20 parts of acrylamide, 14 parts of diacetone acrylamide, 15 parts of soda ash, adjust the pH value to 8.5, stir for 30-60 minutes, blow nitrogen to remove oxygen for 20-40 minutes, when the temperature of the reaction kettle is around 20°C, add them in sequence 1 part of photoinitiator, 1 part of EDTA and 1 part of chain transfer agent, the above reactants are all added according to the aforementioned ratio; this polymerization is an exothermic reaction, with the addition of the three initiators, the temperature of the material will rise slowly, when the temperature When it rises to the highest point and stops rising (1-2 hours), keep the temperature constant and polymerize for 6-8 hours under the irradiation of ultraviolet rays, then gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com