Asphalt composition used for drilling fluid and preparation method thereof

A kind of asphalt composition and drilling fluid technology, applied in the field of oil drilling, to achieve the effect of high brittleness, quality improvement and tight combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

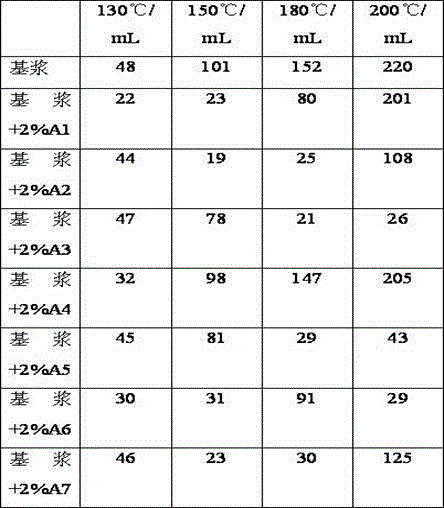

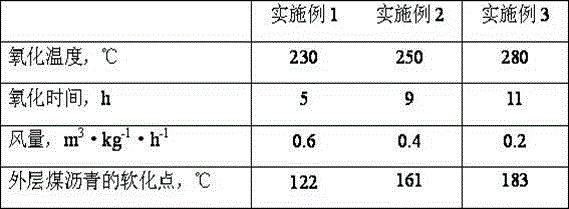

[0026] Add 2g of potassium permanganate to 350g of molten coal tar pitch (softening point: 60°C) and mix evenly, then transfer it to an oxidation kettle for blowing oxidation. Spot the surface of asphalt powder (softening point is 150°C, average particle size is 70 μm), and then cool to room temperature to obtain asphalt composition. The oxidation conditions and product properties are shown in Table 1.

[0027] Add 100g of low-temperature embrittled asphalt composition (low-temperature embrittlement conditions: temperature -25°C, time 8 hours), 16g of graphite and 4g of bentonite into a high-speed pulverizer, mixing time of 5s, pulverization time of 25s, adding 1.5g The water-soluble acrylic resin was mixed for another 4 seconds to obtain asphalt composition particles, denoted as A1, with an average particle size of 100 μm.

Embodiment 2

[0029] Mix 5g of graphite and 5g of bentonite evenly, add to 300g of molten coal tar pitch (softening point is 70°C), mix evenly, then transfer to the oxidation kettle for blowing oxidation, after the reaction is over, spray the oxide material while it is hot to the surface of 100g of high softening point asphalt powder (softening point is 185°C, average particle size is 50μm), and then cooled to room temperature to obtain asphalt composition, oxidation conditions and product properties are shown in Table 1.

[0030]Add 100g of low-temperature embrittled asphalt composition (low-temperature embrittlement conditions: temperature -10°C, time 5 hours), 5g graphite and 5g bentonite into a high-speed pulverizer, mixing time 5s, crushing time 20s, add 2g of The water-soluble acrylic resin was mixed for another 4 seconds to obtain asphalt composition particles, denoted as A2, with an average particle size of 80 μm.

Embodiment 3

[0032] 150g of molten coal tar pitch (softening point: 90°C) was added to the oxidation kettle for air blowing oxidation. After the reaction, the oxide material was sprayed onto the surface of 100g of high softening point asphalt powder (softening point: 200°C, average particle size diameter of 30 μm), and then cooled to room temperature to obtain a bituminous composition, the oxidation conditions and product properties are shown in Table 1.

[0033] 100g of asphalt composition, 3g of graphite, 6g of montmorillonite and 0.5g of cetyltrimethylammonium bromide were added to the high-speed pulverizer, the mixing time was 5s, and the pulverization time was 30s to obtain the asphalt composition particles, denoted as A3, its average particle size is 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com