Polyaspartate polyurea adhesive and preparation method thereof

A polyaspartate and adhesive technology, applied in the direction of adhesive additives, non-polymer adhesive additives, etc., can solve the problems of low bonding strength, chemical corrosion resistance and weather resistance, etc. Achieve the effect of low VOC content, excellent chemical resistance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

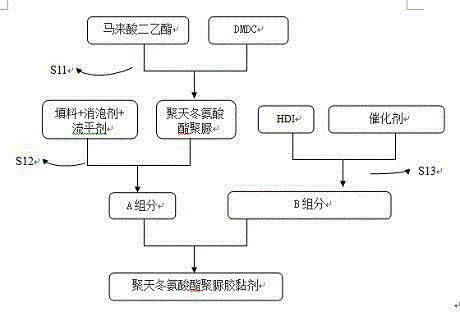

[0041] Correspondingly, the embodiment of the present invention also provides a preparation method of the above polyaspartate polyurea adhesive. This preparation method comprises the steps:

[0042] Step S01. The preparation method of component A includes the following steps: according to the ingredients and content in component A of the polyaspartic ester polyurea adhesive described above, each raw material is obtained respectively, and then the components are mixed. material handling;

[0043] Step S02. Obtain the B-component hexamethylene diisocyanate trimer;

[0044] Step S03. Separately package the prepared components A and B.

[0045]Specifically, in the above-mentioned step S01, each component of component A is as described above, and in order to save space, details are not repeated here.

[0046] Wherein, the polyaspartic ester polyurea can be prepared according to the above-mentioned preparation method of the polyaspartic ester polyurea. In one embodiment, when th...

Embodiment 1

[0058] A polyaspartic acid ester polyurea adhesive and a preparation method thereof. The polyaspartic ester polyurea adhesive includes A and B components separated from each other before use, and the A and B components are mixed according to the weight ratio of 4:1 during use; wherein,

[0059] The A component includes the following components by weight:

[0060] Polyaspartic ester polyurea 4.4 parts

[0061] Kaolin 2 parts

[0062] 2 parts heavy calcium carbonate

[0063] Defoamer 0.005 part

[0064] Leveling agent 0.005 parts;

[0065] The B component is: hexamethylene diisocyanate trimer.

[0066] Its preparation method technological process is as follows figure 1 As shown, it includes the following steps:

[0067] S11. Add diethyl maleate and 3,3-dimethyl-4,4-diaminodicyclohexylmethane in a weight ratio of 1.73:2.71 to the reactor, heat up to 60-80°C, and react under stirring After 72 hours, cool down to room temperature to obtain a reaction solution containing pol...

Embodiment 2

[0071] A polyaspartic acid ester polyurea adhesive and a preparation method thereof. The polyaspartic ester polyurea adhesive includes A and B components separated from each other before use, and the A and B components are mixed according to the weight ratio of 4:1 during use; wherein,

[0072] The A component includes the following components by weight:

[0073] Polyaspartic ester polyurea 4.6 parts

[0074] Kaolin 2 parts

[0075] 2.2 parts of 200 mesh fine sand

[0076] Defoamer 0.005 part

[0077] Leveling agent 0.005 parts;

[0078] The B component is: hexamethylene diisocyanate trimer.

[0079] Its preparation method technological process is as follows figure 1 As shown, it includes the following steps:

[0080] S21. Add diethyl maleate and 3,3-dimethyl-4,4-diaminodicyclohexylmethane in a weight ratio of 1.80:2.80 to the reactor, heat up to 60-80°C, and react under stirring After 72 hours, cool down to room temperature to obtain a reaction solution containing pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com