Control method of IGBT inversion submerged arc welding machine

A technology of a submerged arc welding machine and a control method, applied in arc welding equipment, manufacturing tools, welding equipment and other directions, can solve the problems of difficulty in power supply debugging and further development work, complicated circuits, weak anti-interference ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The control method of the IGBT inverter submerged arc welding machine of the present invention will be further described in detail below.

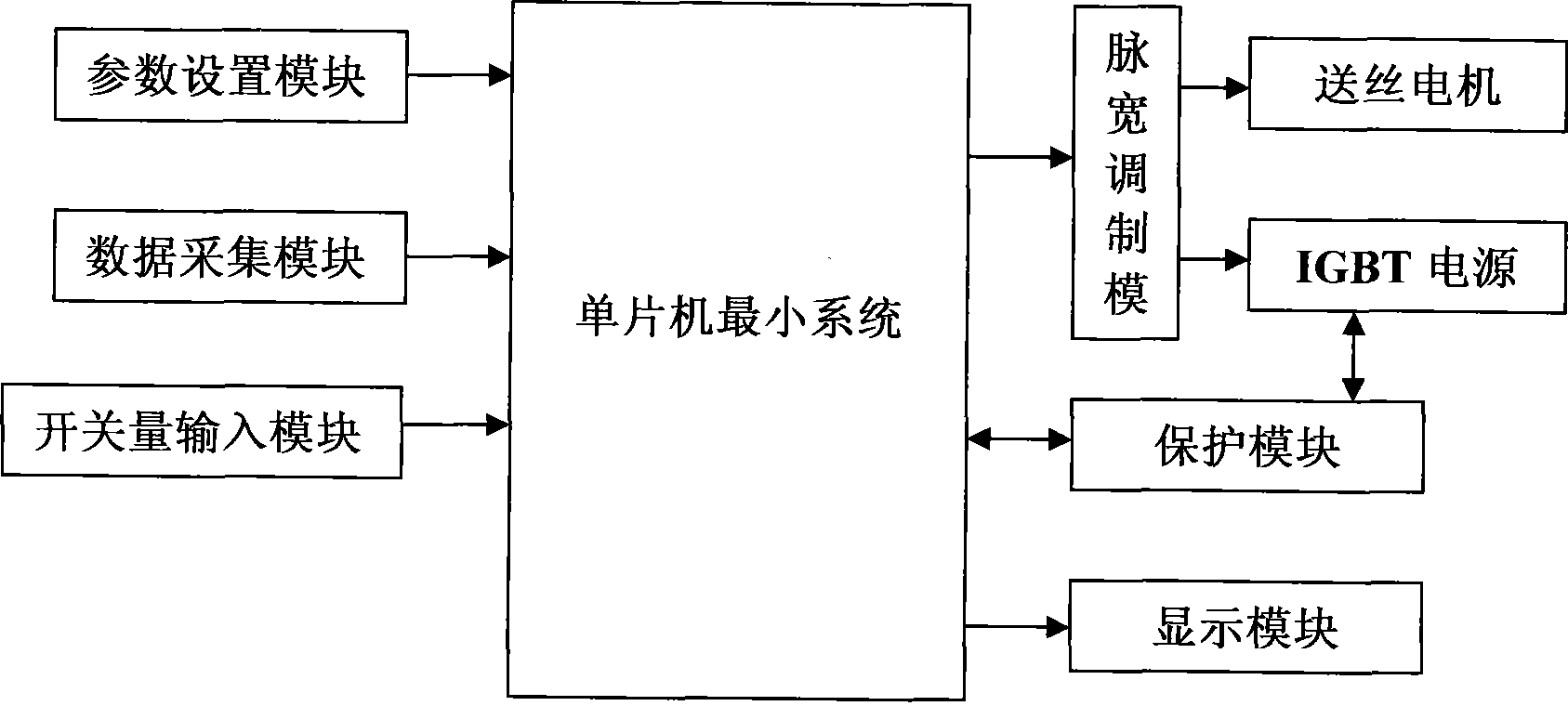

[0016] see figure 1 As shown, the IGBT inverter submerged arc welding machine control system used in the present invention includes a minimum single-chip system, a parameter preset module, a switch value input module, a pulse width modulation module, a data acquisition module, a protection module and a display module, and the minimum single-chip The system is electrically connected to the above modules respectively, the minimum system of the single chip microcomputer is also used to electrically connect the trolley motor, the pulse width modulation module is used to electrically connect the IGBT power supply and the wire feeding motor respectively, and the protection module is electrically connected to the IGBT power supply.

[0017] Preferably, the minimum system of the single-chip microcomputer includes a single-chip microcomputer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com