Multifunctional vulcanized rubber containing polyvinylpyrrolidone-modified graphene oxide and preparation method of multifunctional vulcanized rubber

A technology of polyvinylpyrrolidone and stone oxide, which is applied in the field of rubber polymer composite materials and its preparation, to achieve the effect of simple and convenient preparation steps and excellent mechanics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of preparation method of the multifunctional rubber vulcanizate containing modified graphene oxide of the present invention comprises the following steps:

[0026] Step 1: Preparation of polyvinylpyrrolidone-modified graphene oxide: Add graphite oxide to the aqueous solution, ultrasonically disperse, ultrasonic time 0.5-1h, power 100-300W, add polyvinylpyrrolidone, continue ultrasonic stirring, ultrasonic time 0.5 -1h, power 100-300W, obtain polyvinylpyrrolidone modified graphene oxide aqueous solution;

[0027] Step 2: mixing and stirring the polyvinylpyrrolidone-modified graphene oxide aqueous solution prepared in step 1 with rubber latex, adding a gelling agent, washing and drying the gel to obtain a rubber mixture containing polyvinylpyrrolidone-modified graphene oxide;

[0028] Step 3: After mixing the rubber mixture containing polyvinylpyrrolidone modified graphene oxide obtained in step 2 with zinc oxide, stearic acid, anti-aging agent, accelerator and vul...

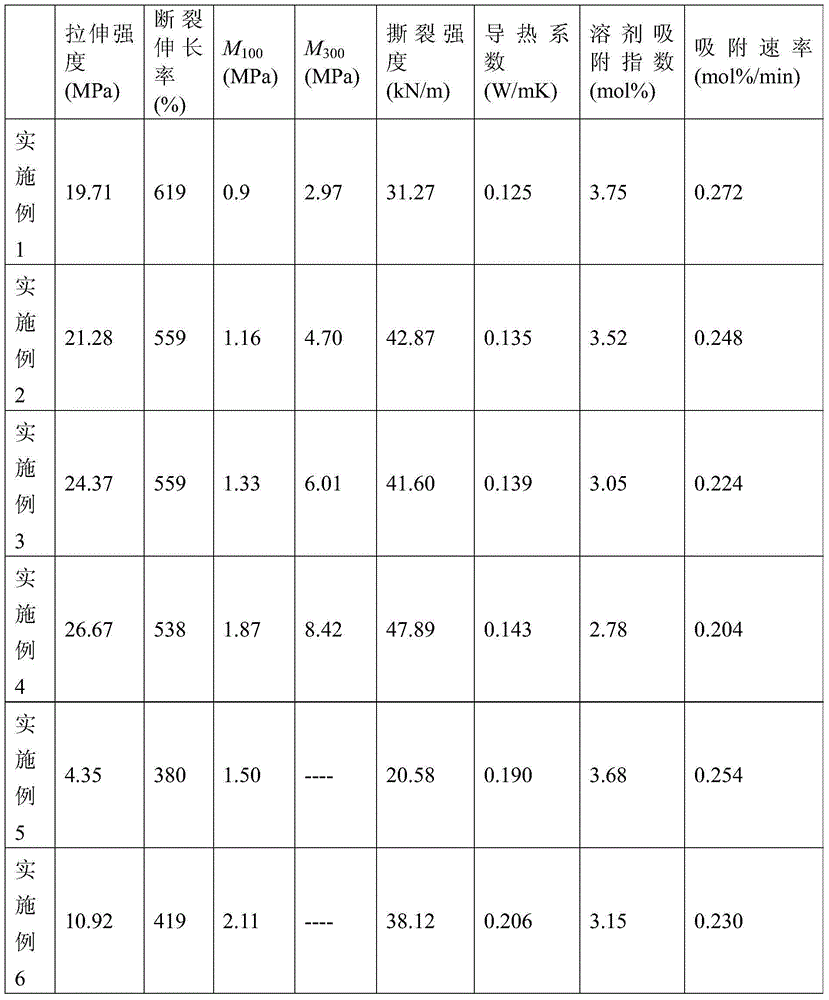

Embodiment 1

[0040] Disperse 1 part of graphite oxide in the aqueous solution, 100W ultrasonic 1h, add 1 part of polyvinylpyrrolidone, power 100W ultrasonic stirring 1h, obtain polyvinylpyrrolidone modified graphene oxide aqueous solution, wherein the size of polyvinylpyrrolidone modified graphene oxide is as follows figure 2; Add it dropwise to natural rubber latex, mix and stir, and add a gel agent, wash and dry the gel to obtain a rubber mixture containing 1 part of modified graphene oxide; further mix it with 3 parts of zinc oxide, 1 part of Stearic acid, 2 parts of RD, 0.5 parts of DM and 3 parts of sulfur are mixed on the open mill, parked, and the vulcanization time is measured with a vulcanizer, and then the rubber vulcanizate is obtained with a flat vulcanizer. Among them, the XRD diffraction of vulcanized rubber is as follows figure 1 shown. The detailed properties of the vulcanizate are shown in Table 1.

Embodiment 2

[0042] Repeat the method of Example 1 according to the specified content of each component, but adopt 2 parts of polyvinylpyrrolidone-modified graphene oxide in the formula. The detailed properties of the vulcanizate are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com