Method for purifying sulfurol

A purification method, the technology of thiothiazole, which is applied in the field of thiothiazole purification, can solve the problems of low production efficiency, non-bean flavor, and impure aroma, etc., and achieve the effects of improving purification purity, intuitive operation, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

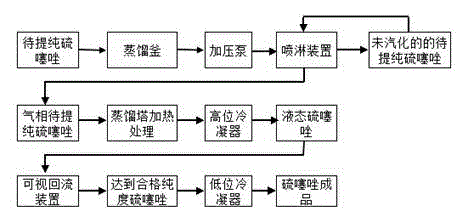

[0021] figure 1 Shown a kind of purification method of thiothiazole, comprises the following steps:

[0022] a. Put the sulfur thiazole to be purified into the distillation kettle through the feed port, open the vacuum pump and vacuum valve at the same time to enter the booster pump, enter the spray device through the pipeline, and obtain the sulfur thiazole to be purified in the gas phase, and recycle the sulfur thiazole to be purified without vaporization. pressure spray; b. when the gas phase to be purified sulfur thiazole in the step a rises to the distillation tower, the distillation tower is heated again, and then the gas phase to be purified sulfur thiazole continues to rise to the high-level condenser to become liquid sulfur Thiazole drops into the collector; c. the liquid sulfur thiazole in the step b enters the visual reflux device made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com