Special strain culture medium for mushroom liquefaction and corresponding culture method

A strain culture medium and strain culture technology, which are applied in mushroom cultivation, application, cultivation and other directions, can solve the problems that liquid fermentation strains cannot be applied on a large scale, increase the risk of fruiting bag pollution, and produce fruiting bag pollution accidents. , to achieve the effect of eliminating secondary pollution, solving the cultivation of provenance, and reducing the amount of inoculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

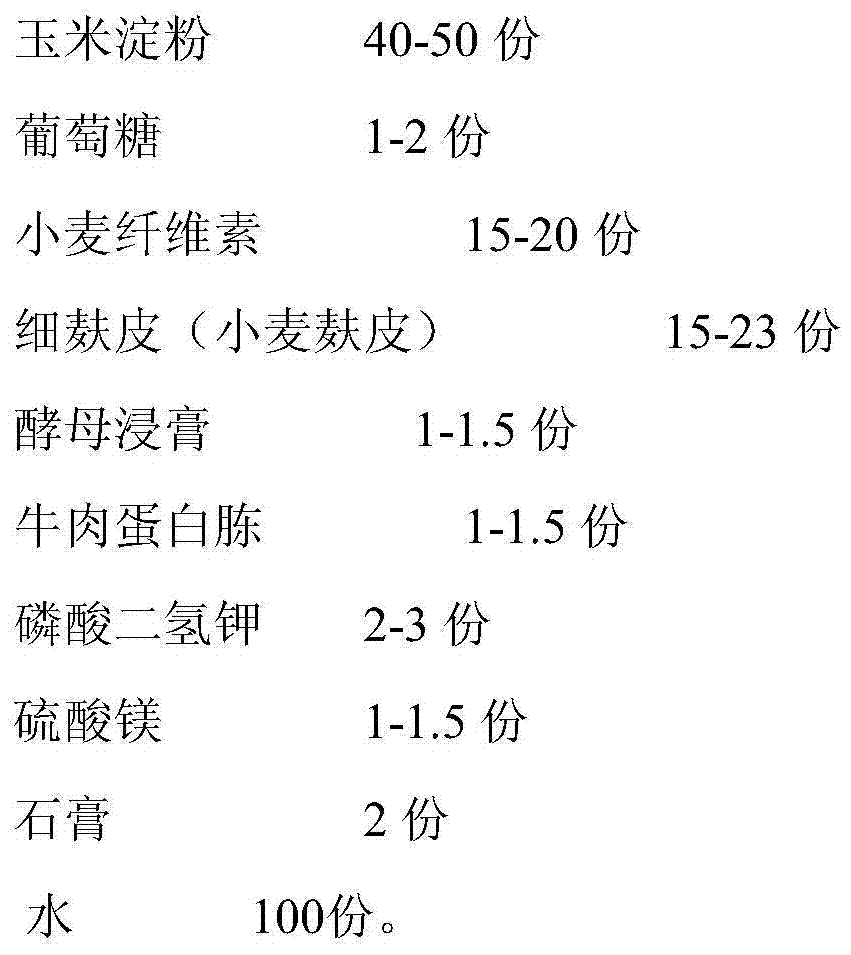

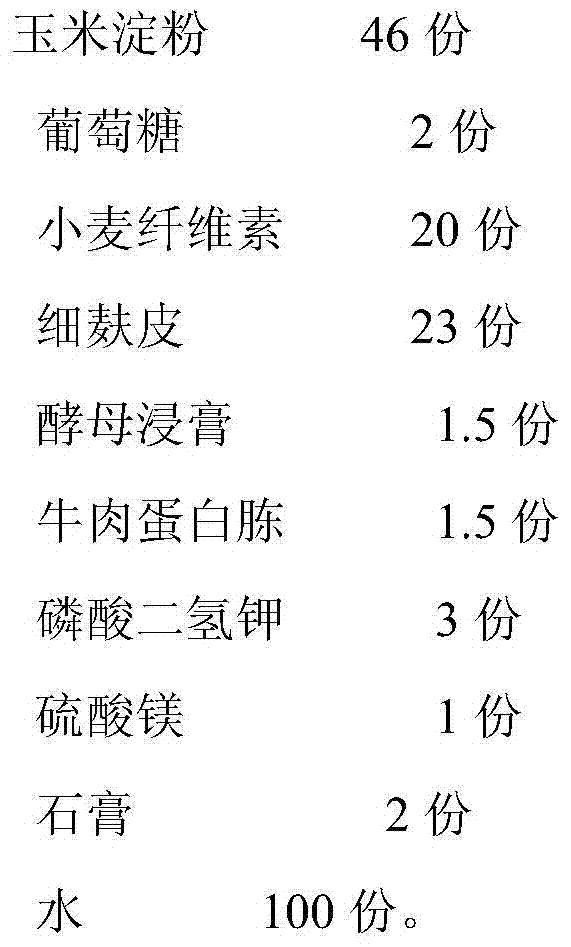

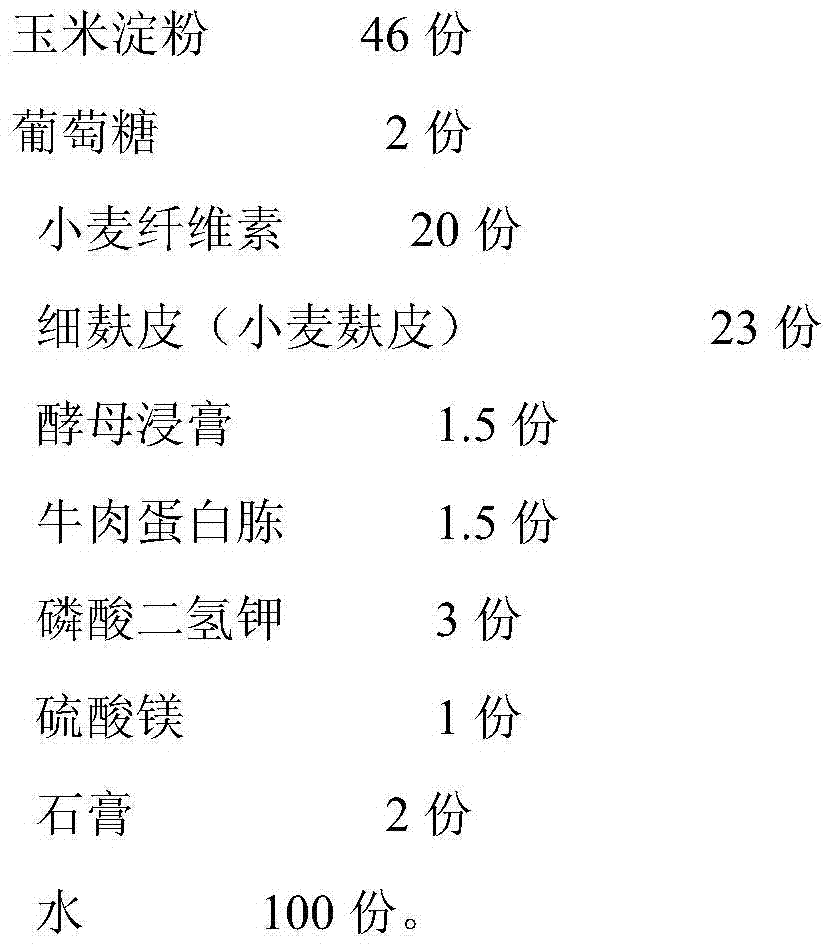

[0037] Embodiment 1, a kind of culture medium special for mushroom liquefaction, it is made up of the composition of following parts by weight:

[0038]

[0039] The preparation method of above-mentioned culture medium is to carry out following steps successively:

[0040] In a stainless steel container, cornstarch, fine bran (wheat bran), wheat cellulose, and gypsum are mixed uniformly under dry conditions to obtain ingredient I;

[0041] Add glucose, yeast extract, beef peptone, potassium dihydrogen phosphate, and magnesium sulfate into water, and fully stir (dissolve glucose, yeast extract, beef peptone, potassium dihydrogen phosphate, and magnesium sulfate in water) to obtain ingredient II;

[0042] After ingredients I and II are fully mixed, a culture medium dedicated to the liquefaction of shiitake mushrooms is obtained.

[0043] Remarks: The special culture medium for mushroom liquefaction is prepared and used now.

Embodiment 2

[0044] Embodiment 2, utilize the mushroom liquefaction strain culture method that the substratum of embodiment 1 gained carries out, the female kind of mushroom is carried out following steps successively:

[0045] 1), strain production:

[0046] Immediately dispense 200 g of the prepared mushroom liquefaction-specific culture medium into 200 ml special culture bottles, cover the microporous membrane vent cap (choose ZP14-200 vent culture bottle from Shanghai Suntuo Industrial Co., Ltd.), and store at 121 ° C. , Under 0.11Mpa, carry out high temperature and high pressure sterilization for 90 minutes; obtain the culture medium after sterilization;

[0047] Under sterile conditions, insert 5 grams of shiitake mushroom mother species (solid mother species) into the above-mentioned sterilized medium, and culture in the dark at 23°C for 25 days to obtain solid strains for liquefaction; at this time, the mycelia fill the whole bottle.

[0048] After testing, the purity is 100%;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com