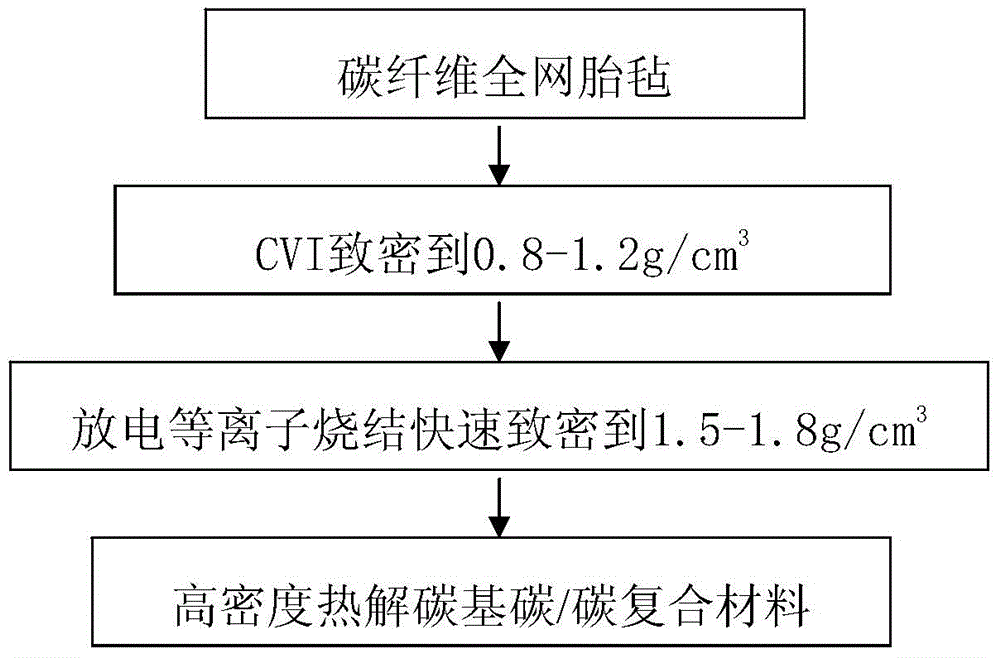

Rapid densification method of carbon/carbon composite material

A carbon composite material and composite material technology are applied in the field of rapid preparation of carbon/carbon composite materials to achieve the effect of improving densification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Set the initial density to 0.19g / cm 3 The carbon fiber full mesh felt is densified to 0.9g / cm by CVI 3 , control the pyrolytic carbon microstructure of the substrate to rough layer structure pyrolytic carbon; CVI process parameters are: temperature: 1180 °C; pressure: 15KPa; propylene flow rate: 6.0L / min; nitrogen flow rate: 9L / min; time: 50h.

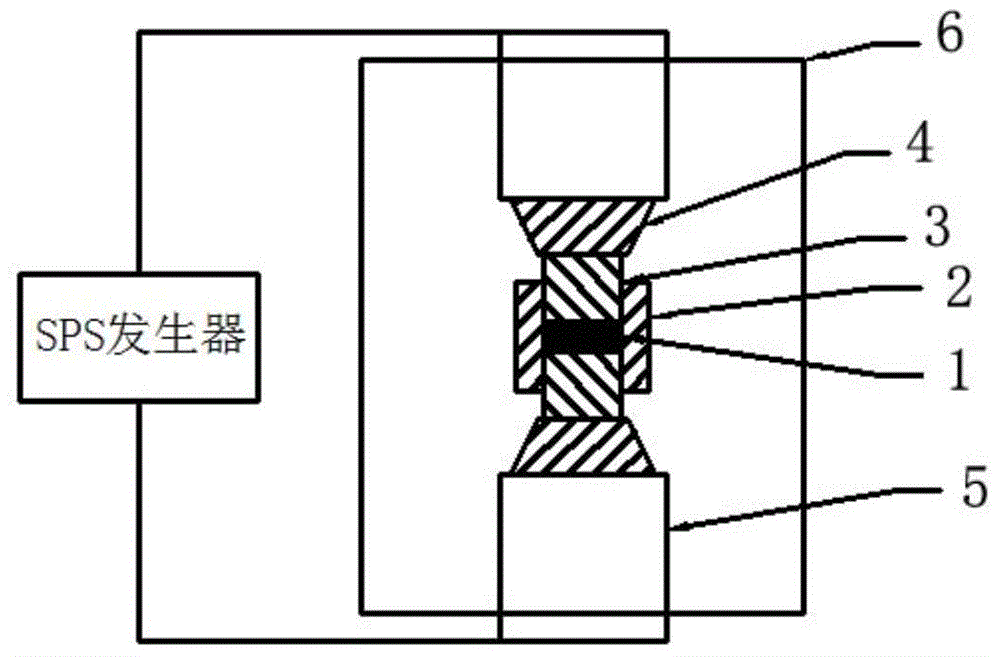

[0039] (2) The carbon / carbon composite material is machined into a workpiece with a diameter of 40 mm and a height of 10 mm, which is loaded into a graphite mold in an SPS furnace and pre-pressed with a force of 5KN to keep the surface of the sample flat.

[0040] (3) Using SPS furnace, vacuumize to 10 -2 After Pa, the carbon / carbon composite material is rapidly heated to a temperature of 1700°C, then slowly pressurized to a pressure of 31MPa, the temperature rise rate is controlled to be 140°C / min, and the pressurization rate is 0.5MPa / min;

[0041] (4) Insulation and pressure holding for 25 minutes, cooling and pressure ...

Embodiment 2

[0043] (1) Set the initial density to 0.15g / cm 3 The carbon fiber full mesh tire felt is densified to 1.32g / cm by CVI 3 , control the pyrolytic carbon microstructure of the substrate to rough layer structure pyrolytic carbon; CVI process parameters are: temperature: 1190 °C; pressure: 12kPa; propylene flow rate: 5.0L / min; nitrogen flow rate: 8L / min; time: 80h.

[0044](2) The carbon / carbon composite material is machined into a workpiece with a diameter of 40 mm and a height of 10 mm, which is loaded into a graphite mold in an SPS furnace and pre-pressed with a force of 5KN to keep the surface of the sample flat.

[0045] (3) Using SPS furnace, vacuumize to 10 -2 After Pa, the carbon / carbon composite material is rapidly heated to a temperature of 2000°C, then slowly pressurized to a pressure of 35MPa, and the temperature rise rate is controlled to be 120K / min, and the pressurization rate is 0.6MPa / min;

[0046] (4) Insulation and pressure holding for 30 minutes, cooling and p...

Embodiment 3

[0048] (1) Set the initial density to 0.2g / cm 3 The carbon fiber full mesh felt is densified to 1.15g / cm by CVI 3 , control the pyrolytic carbon microstructure of the substrate to rough layer structure pyrolytic carbon; CVI process parameters are: temperature: 1200 °C; pressure: 12kPa; methane flow rate: 7.0L / min; nitrogen flow rate: 11L / min; time: 70h.

[0049] (2) The carbon / carbon composite material is machined into a workpiece with a diameter of 40 mm and a height of 10 mm, which is loaded into a graphite mold in an SPS furnace and pre-pressed with a force of 5KN to keep the surface of the sample flat.

[0050] (3) Using SPS furnace, vacuumize to 10 -2 After Pa, the carbon / carbon composite material is rapidly heated to a temperature of 2100°C, then slowly pressurized to a pressure of 38MPa, and the temperature increase rate is controlled to be 180K / min, and the pressurization rate is 0.8MPa / min;

[0051] (4) Insulation and pressure holding for 15 minutes, cooling and pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com