Treatment method for reverse osmosis concentrated water

A reverse osmosis concentrated water and treatment method technology, which is applied in the field of reverse osmosis concentrated water standard treatment, can solve the problems of poor biodegradability, failure to meet COD emission standards, continuous and stable operation of ozone generators, ozone generation cost problems, etc., to achieve well-developed pores , Remarkable treatment effect, good chroma removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

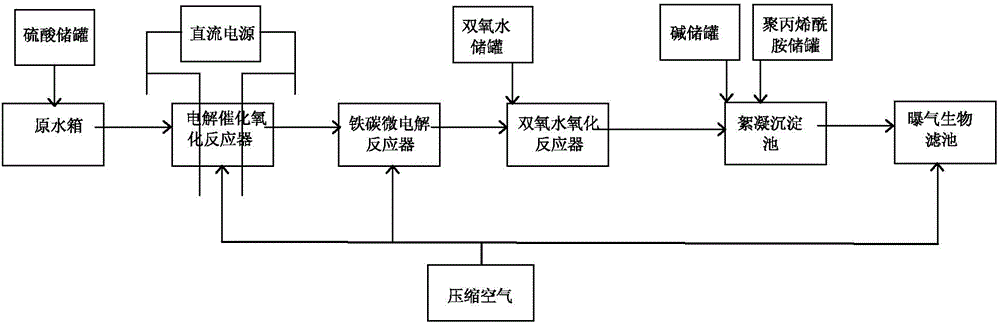

[0038] The reverse osmosis concentrated water of a biochemical standard wastewater reuse unit in an oil refinery, with a COD of 200mg / L, enters figure 1 In the process flow shown, the main process parameters of each processing unit are:

[0039] (1) Electrolytic catalytic oxidation. The reverse osmosis concentrated water is added sulfuric acid to the raw water tank to adjust the pH value to 3.0, and enters the electrolytic catalytic oxidation reactor for electrolytic catalytic oxidation. The catalyst in the electrolytic catalytic oxidation reactor supports metal ions including Cu 2+ , Fe 2+ , Fe 3+ , Mn 2+ 、Ni 2+ , the electrode material is 316L stainless steel, the electrode spacing is 2cm, and the current density is 20mA / cm 2 , the reaction time is 30 minutes, and the COD of the electrolytic catalytic oxidation water is 97mg / L.

[0040] (2) Iron-carbon micro-electrolysis. The iron-carbon micro-electrolysis reactor is filled with iron-carbon fillers, the reaction gas-w...

Embodiment 2

[0045] The reverse osmosis concentrated water of a biochemical standard sewage reuse device in an oil refinery, with a COD of 180mg / L, enters figure 1 In the process flow shown, the main process parameters of each processing unit are:

[0046] (1) Electrolytic catalytic oxidation. Sulfuric acid is added to the raw water tank to adjust the pH value to 2.8, and the reverse osmosis concentrated water enters the electrolytic catalytic oxidation reactor for electrolytic catalytic oxidation. The catalyst in the electrolytic catalytic oxidation reactor carries metal ions including Cu 2+ , Fe 2+ , Fe 3+ , Mn 2+ , the electrode material is 316L stainless steel, the electrode spacing is 4cm, and the current density is 27mA / cm 2 , the reaction time is 25 minutes, and the COD of the electrolytic catalytic oxidation water is 90mg / L.

[0047] (2) Iron-carbon micro-electrolysis. The iron-carbon micro-electrolysis reactor is filled with iron-carbon fillers, the reaction gas-water ratio ...

Embodiment 3

[0052] The reverse osmosis concentrated water of a biochemical standard sewage reuse device in an oil refinery, with a COD of 150mg / L, enters figure 1 In the process flow shown, the main process parameters of each processing unit are:

[0053] (1) Electrolytic catalytic oxidation. The concentrated reverse osmosis water is added with hydrochloric acid to the raw water tank to adjust the pH value to 2.7, and enters the electrolytic catalytic oxidation reactor for electrolytic catalytic oxidation. The catalyst in the electrolytic catalytic oxidation reactor carries metal ions including Cu 2+ , Fe 2+ , Fe 3+ , Mn 2+ , the material of the electrode material is carbon, the electrode spacing is 3cm, and the current density is 15mA / cm 2 , the reaction time is 20 minutes, and the COD of the electrolytic catalytic oxidation water is 72mg / L.

[0054] (2) Iron-carbon micro-electrolysis. The iron-carbon micro-electrolysis reactor is filled with iron-carbon fillers, the reaction gas-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com