Method for modifying desulfuration ash for cement retarder

A technology of cement retarder and desulfurization ash, applied in the field of cement retarder, can solve the problems that desulfurization ash cannot be directly used as cement retarder and environmental pollution, so as to improve oxidation efficiency, shorten reaction time and solve environmental problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

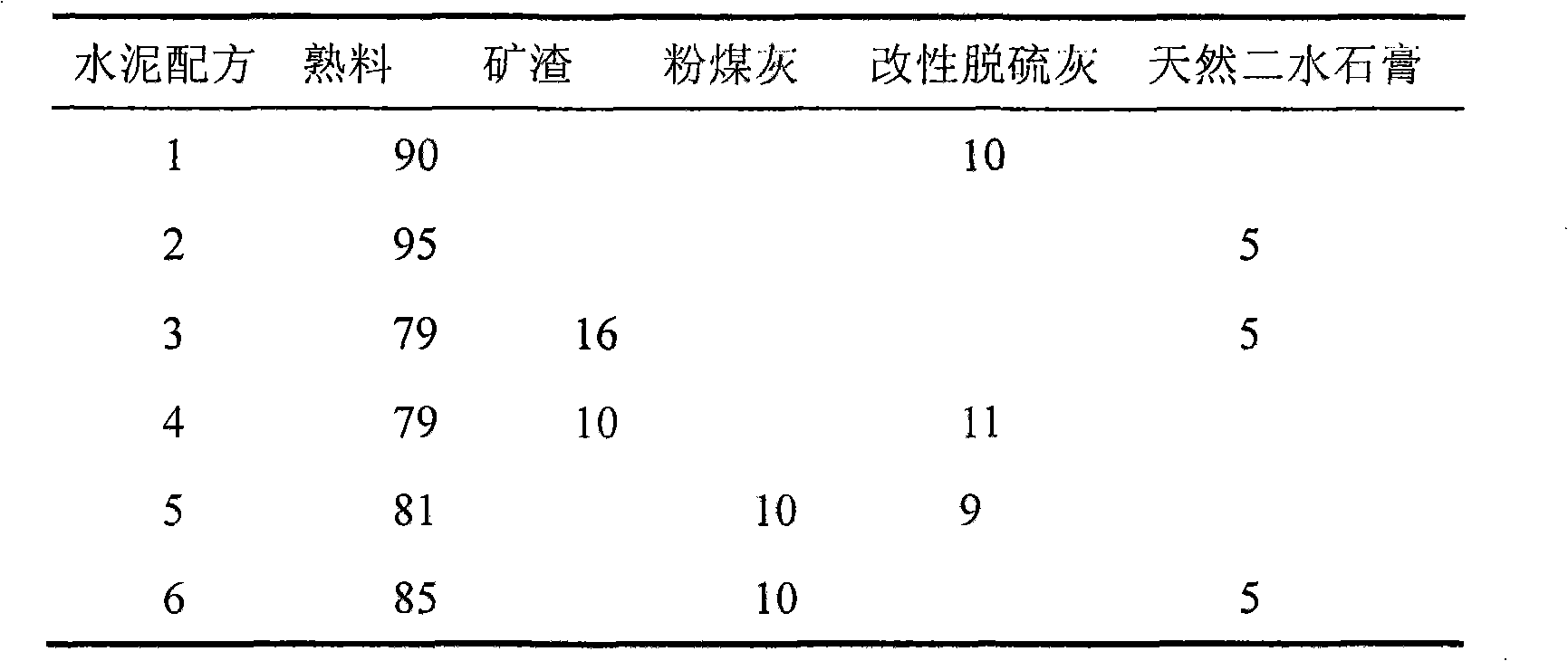

Examples

Embodiment 1

[0014] Take 1 kg of desulfurized ash, and ball mill it for 30 minutes to obtain a crushed desulfurized ash with a specific surface area of 650m2 / kg, and then treat it at 500°C for 30 minutes, and the oxidation rate of calcium sulfite is 98.6%.

Embodiment 2

[0016] Take 1 kg of desulfurized ash, and ball mill it for 40 minutes to obtain a specific surface area of 690m2 / kg, and then treat it at 480°C for 30 minutes, and the oxidation rate of calcium sulfite is 98.8%.

Embodiment 3

[0018] Take 1 kg of desulfurized ash, and ball mill it for 25 minutes to obtain a crushed desulfurized ash with a specific surface area of 620m2 / kg, and then treat it at 550°C for 30 minutes, and the oxidation rate of calcium sulfite is 97.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com