Aerobic granular sludge culture method

A technology of aerobic granular sludge and cultivation method, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc. It does not meet the actual problems of petrochemical wastewater treatment, and achieves the effect of overcoming bottlenecks and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

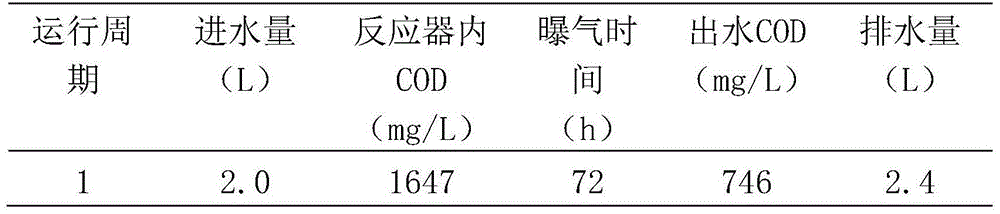

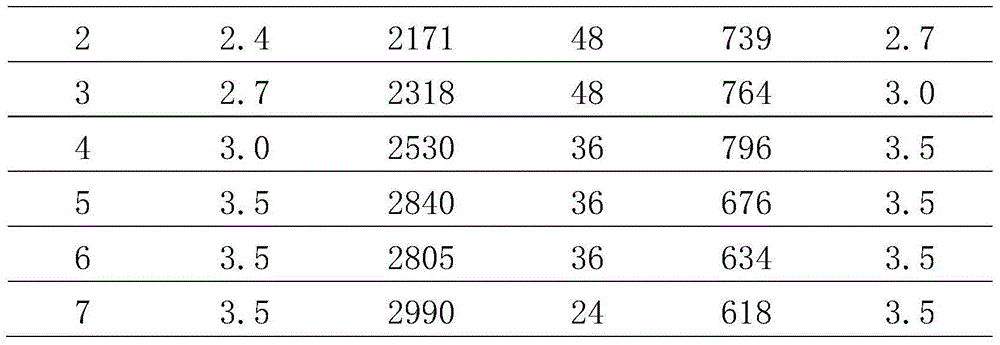

Examples

Embodiment Construction

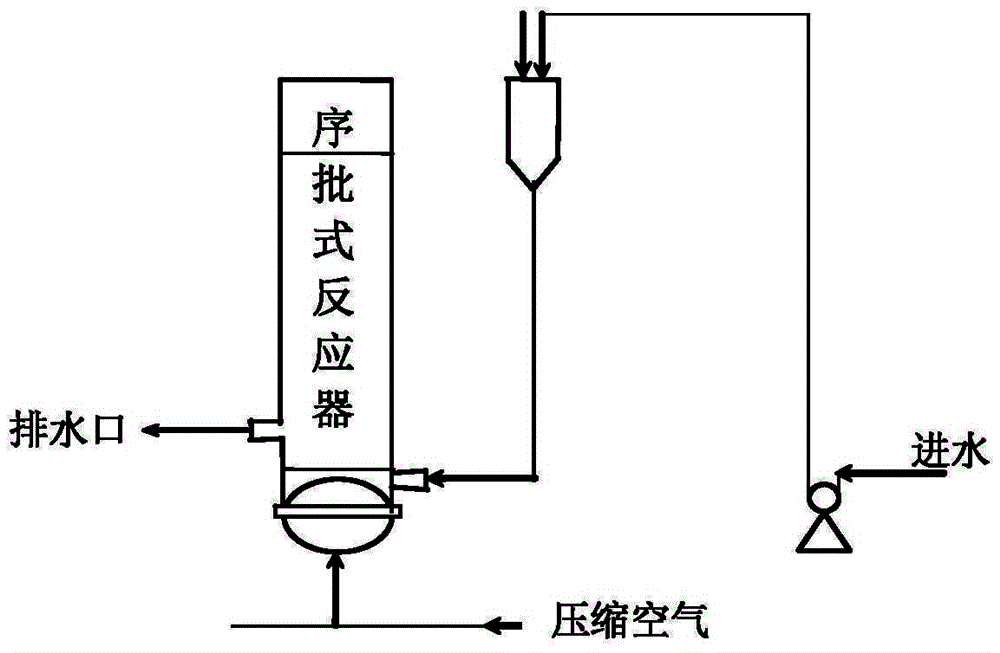

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0039] The cultivation method of aerobic granular sludge of the present invention comprises the following steps:

[0040] Step 1, inoculation: inoculate the activated sludge in the sequencing batch reactor;

[0041] Step 2. Water intake: first use sulfuric acid to adjust the pH value of the petrochemical wastewater to be treated between 8.0 and 9.0, and then pump the petrochemical wastewater with adjusted pH value into the reactor through the water inlet at the bottom of the sequencing batch reactor (reactor is the abbreviation of sequence batch reactor);

[0042] Step 3. Aeration: Aeration is carried out through the aeration device laid at the bottom of the reactor, so that the activated sludge and petrochemical wastewater are fully mixed and reacted; compressed air is sent into the aeration device through the pipeline;

[0043] Step 4, sedimentation: stop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com