A kind of polyaluminium-modified sodium alginate inorganic-organic composite flocculant and preparation method thereof

A composite flocculant and sodium alginate technology, applied in the field of environmental chemistry, can solve problems such as unsatisfactory effects, and achieve good coagulation treatment effect, good flocculation effect, and good product stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

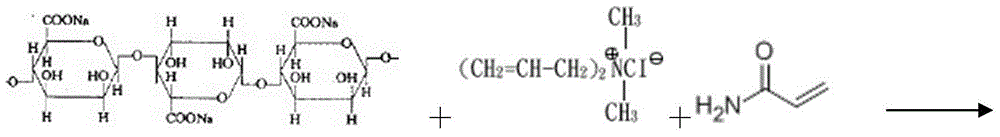

Method used

Image

Examples

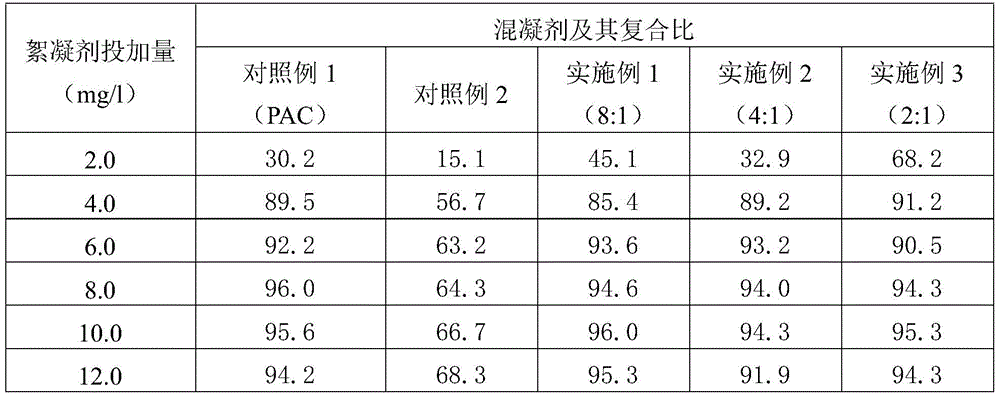

Embodiment 1

[0043] The preparation method of the polyaluminum-modified sodium alginate inorganic-organic composite flocculant with a composite ratio of PAC and modified sodium alginate of 8:1 comprises the following steps:

[0044] (1) Preparation of Polyaluminum Chloride

[0045] 22.3546g AlCl 3 ·6H 2 O was dissolved in 100ml deionized water to get 9.8125g Na 2 CO 3 Add a little distilled water to dissolve, add Na under magnetic stirring 2 CO 3 Adjust the alkalization degree of the solution, stir and react at room temperature for 2 hours, and set the volume to 250mL to obtain a polyaluminum chloride solution with an alkalization degree of 2 and a concentration of 10g / L;

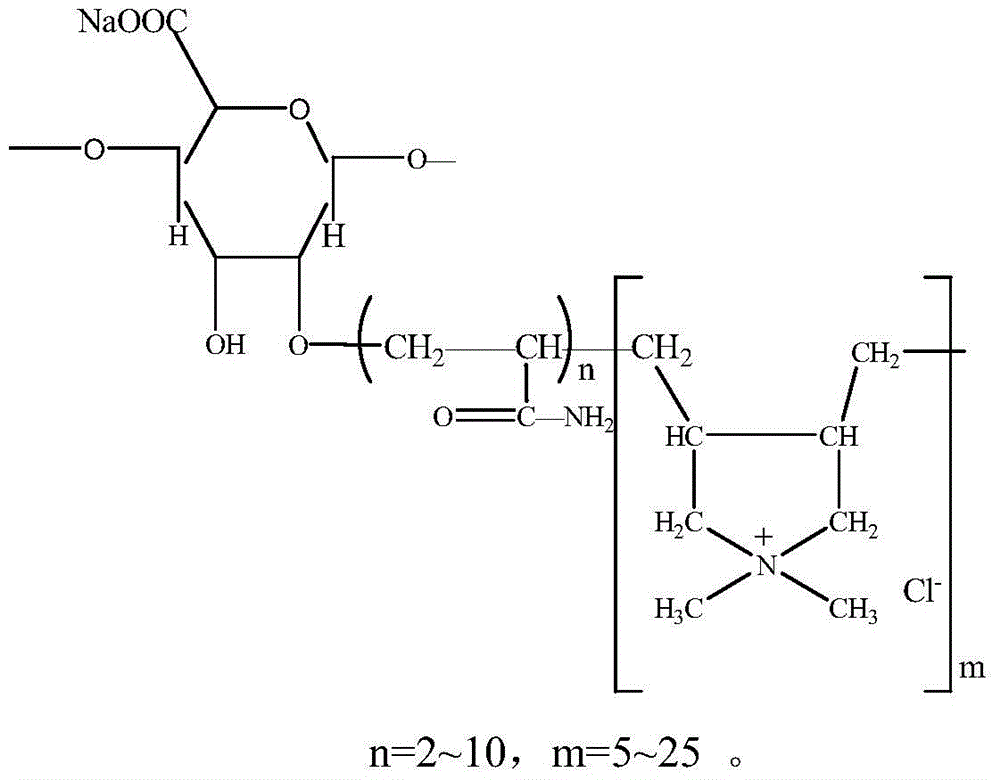

[0046] (2) Preparation of modified sodium alginate

[0047] Weigh 1.0g of natural sodium alginate SA, add 100mL deionized water and stir fully at a temperature of 50°C. After the sodium alginate is completely dissolved in water, add it to a reactor equipped with a stirring device, protect it under nitrogen, and wa...

Embodiment 2

[0052] The preparation of polyaluminum-modified sodium alginate inorganic-organic composite flocculant with a compound ratio of PAC and modified sodium alginate of 4:1, the preparation method is the same as in Example 1, except that:

[0053] In step (3), the amount of modified sodium alginate with a concentration of 1 g / L is 25 mL.

Embodiment 3

[0055] The preparation of polyaluminum-modified sodium alginate inorganic-organic composite flocculant with a composite ratio of PAC and modified sodium alginate of 2:1, the preparation method is the same as in Example 1, the difference is that:

[0056] In step (3), the added amount of modified sodium alginate with a concentration of 1 g / L is 50 mL.

[0057] Comparative example 1 degree of alkalinity is 2, the preparation of the PAC of concentration 10g / L:

[0058] (1) Weigh 22.3546g of AlCl3·6H2O solid in a beaker, add appropriate amount of distilled water to dissolve, place on a magnetic stirrer, weigh 9.8125g of Na2CO3 and add a little distilled water to dissolve. Add Na2CO3 solution dropwise to the AlCl3 solution under magnetic stirring, continue to stir for 2 hours after the dosing, and set the volume to 250mL to obtain polyaluminum chloride with a degree of alkalinity of 2.10g / L.

[0059] (2) Pipette the above 10mL PAC and dilute to 100mL to obtain 1g / L PAC for use.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com