Method for preparing beta-molecular sieve from oil shale waste

A technology of β molecular sieve and oil shale slag, which is applied in the field of in-situ crystallization to synthesize β molecular sieve, which can solve the problems of ineffective use of aluminum elements, large energy consumption, and high requirements for containers, and achieve low cost, large external area, and diffusion long range short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Using oil shale slag as raw material, according to the liquid-solid ratio of 10mL / g, the oil shale slag was mixed with NaOH, K 2 CO 3 , TEAOH mixed alkali solution (NaOH, K in the alkali solution 2 CO 3 , TEAOH mass fractions were 15%, 10% and 5%) at room temperature for 1 h, washed, dried, crushed to 7 μm, and roasted at 800 °C in a muffle furnace at a heating rate of 5 °C / min for 4 h to obtain Activate oil shale residue.

Embodiment 2

[0055] Using oil shale slag as raw material, according to the liquid-solid ratio of 10mL / g, put oil shale slag in a mixed alkali solution composed of NaOH, KOH, and TEAOH (the mass fractions of NaOH, KOH, and TEAOH in the alkali solution are respectively 10% , 5% and 5%) at 50°C for 2 h, washed, dried, crushed to 10 μm, and roasted in a muffle furnace at 850°C for 2 h at a heating rate of 10°C / min to obtain activated oil shale slag.

Embodiment 3

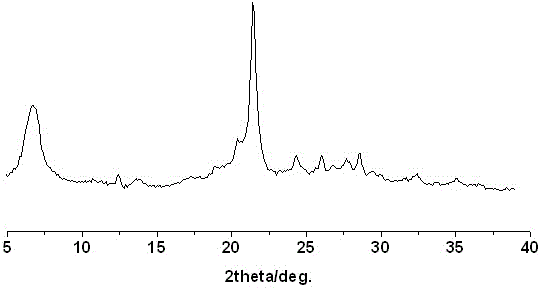

[0057] Soak 20 g of the activated oil shale slag of Example 1 in 40 mL of tetraethylammonium hydroxide with a weight concentration of 25 wt % at 60° C. for 5 h. Then put 1.0g of sodium hydroxide, 0.3g of sodium chloride, 1.0g of potassium chloride, 20mL of distilled water, 30mL of tetraethylammonium hydroxide with a concentration of 25wt%, and 25g of white carbon black into a beaker and stir at 70°C. 4h to make the mixture gel. The gel was transferred to a stainless steel reactor for static crystallization at 140 °C for 48 h. After the crystallization is completed, cool, filter and separate from the mother liquor, wash and dry the filter cake to obtain a crystallized product. According to X-ray measurement, its phase belongs to β molecular sieve, the relative crystallinity of β molecular sieve in the product is 80%, and the crystal grain of molecular sieve reaches 80~120nm. The single-pot yield reaches more than 70wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com