Method for preparing carbon nanotubes by adopting coal tar

A carbon nanotube, coal tar technology, applied in nanotechnology, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of increased raw material cost, poor safety, high price, etc., and achieves simple structure and location. Smooth and improve the effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

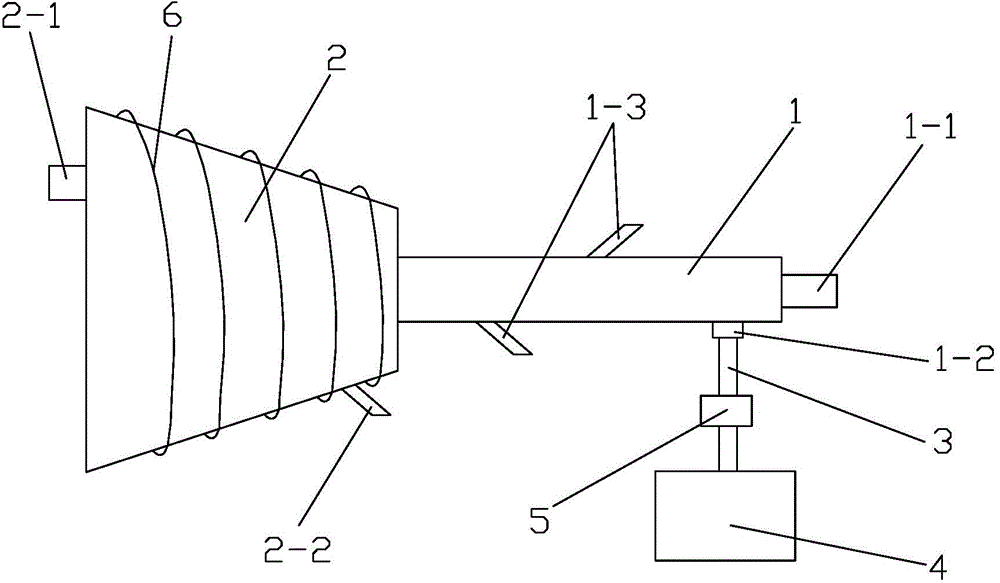

[0034] Such as figure 1 As shown, the coal tar vaporizer of this embodiment includes a vaporization pipeline 1 and a variable-diameter pipeline 2 communicated with the vaporization pipeline 1, and the end of the vaporization pipeline 1 away from the variable-diameter pipeline 2 is provided with a first air inlet 1-1, The pipe wall of the vaporization pipeline 1 is provided with a feed port 1-2, the feed port 1-2 communicates with the coal tar storage tank 4 through the feed pipe 3, and the variable diameter pipe 2 is far away from the vaporization pipe 1 One end of the pipe is closed and provided with an air outlet 2-1, and the size of the end of the reducing pipe 2 away from the vaporization pipe 1 is larger than that of the other end.

[0035] Such as figure 1 As shown, in this embodiment, the vaporization pipe 1 is an internally threaded pipe, and the variable diameter pipe 2 is a variable diameter internally threaded pipe.

[0036] Such as figure 1 As shown, in this emb...

Embodiment 2

[0040] Step 1. Soak ferric oxide powder with a particle size of 45 μm in SnCl with a concentration of 1.5 mol / L 2Carry out sensitization in the solution, the time of sensitization is 50min, dry after filtering, place the ferric oxide powder after the drying in the gas phase depositor, adopt physical deposition to the ferric oxide powder surface in the described vapor phase depositor Nickel plating to obtain an iron-containing catalyst; the pressure of the physical deposition is 0.01Pa, the temperature is 1200°C, and the time is 20min;

[0041] Step 2, using the coal tar vaporizer of Embodiment 1, pass the protective gas into the vaporization pipeline 1 through the first air inlet 1-1, and the flow rate of the protective gas is 100cm 3 / s, negative pressure is generated at the feed port 1-2 while ventilating so that the coal tar in the coal tar storage tank 4 is delivered to the vaporization pipeline 1 by the feed pipe 3, or the feed pipe 3 and the feed pipe 3 are opened while ...

Embodiment 3

[0046] Step 1. Soak ferric oxide powder with a particle size of 35 μm in SnCl with a concentration of 0.5 mol / L 2 Carry out sensitization in the solution, the time of sensitization is 40min, dry after filtering, place the ferric oxide powder after the drying in the vapor phase depositor, adopt physical deposition to the surface of the ferric oxide powder in the vapor depositor Nickel plating to obtain an iron-containing catalyst; the gas pressure of the physical deposition is 0.0001Pa, the temperature is 1000°C, and the time is 10min;

[0047] Step 2, using the coal tar vaporizer of Embodiment 1, pass the protective gas into the vaporization pipeline 1 through the first air inlet 1-1, and the flow rate of the protective gas is 100cm 3 / s, negative pressure is generated at the feed port 1-2 while ventilating so that the coal tar in the coal tar storage tank 4 is delivered to the vaporization pipeline 1 by the feed pipe 3, or the feed pipe 3 and the feed pipe 3 are opened while ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com