Method for preparing thin film ordered microstructure based on a reaction ion beam etching technology

A technology of reactive ion etching and microstructure, which is applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., and can solve problems such as difficult preparation of various patterns

Inactive Publication Date: 2015-04-29

JILIN UNIV

View PDF5 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

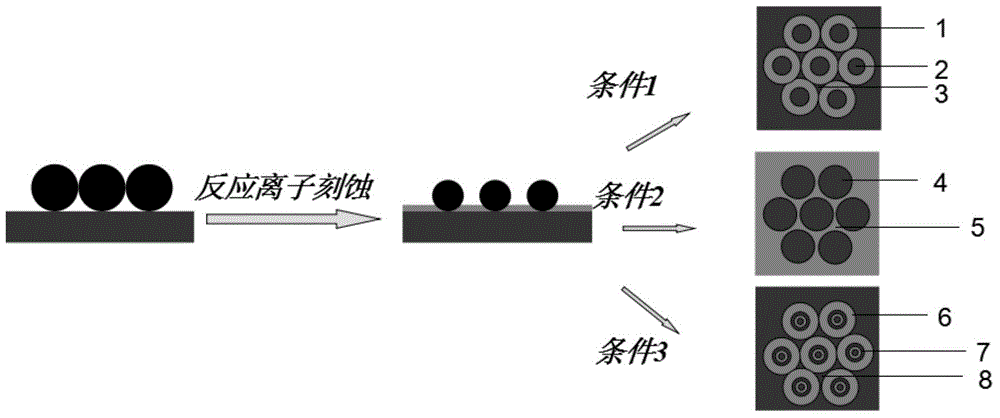

[0005] The deficiencies of the existing technology for preparing thin film patterns include the following two points: 1. New substances need to be introduced; 2. Usually, it is difficult to prepare multiple patterns by using one template

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-7

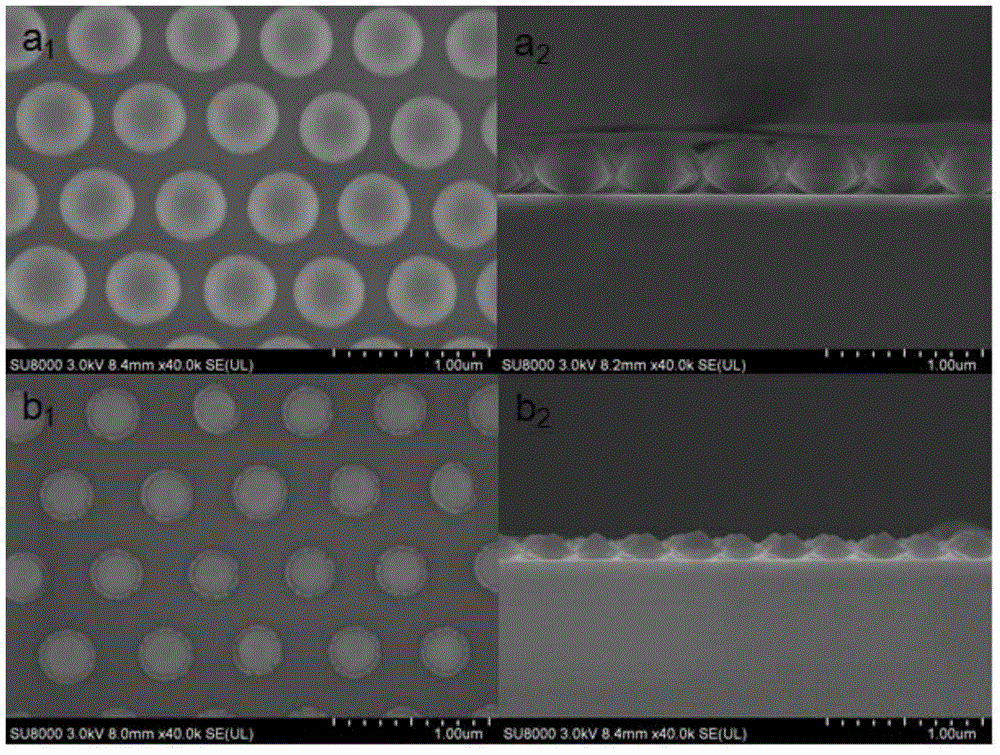

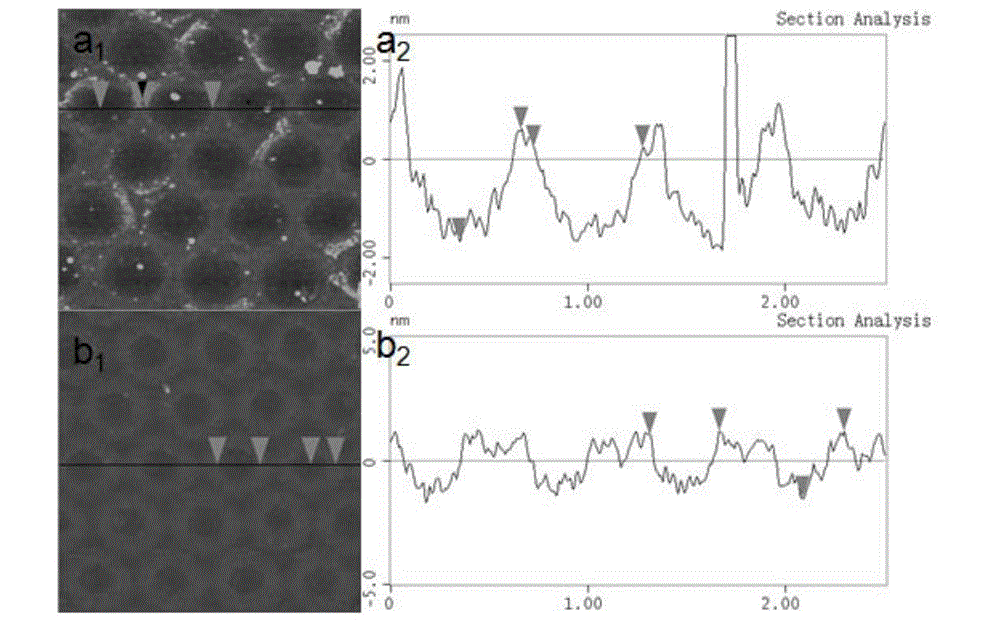

[0050] Put the silicon wafer with polystyrene microspheres into the cavity of the reactive ion etching machine, and vacuumize it. When the pressure reaches 7.26×10 -5 Pa, the program with edited parameters will run. The set parameters are as follows:

Embodiment 1

[0051]Example 1: Condition 1 etching for 1 min; Example 2: Condition 1 etching for 2 min;

Embodiment 3

[0052] Example 3: Condition 2 etching for 3 minutes; Example 4: Condition 2 etching for 9 minutes;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a method for preparing ordered thin film patterns based on a reaction ion etching polymer and belongs to the technical field of ordered microstructures. Specifically, reaction ion etching is conducted on a substrate and single-layer polymeric microspheres on the surface of the substrate, accordingly the ordered thin film patterns are formed on the surface of the substrate and can be regulated and controlled by changing reaction ion etching parameters. Furthermore, electroless deposition is conducted on the surface of the substrate, metal nano particles can be selectively absorbed in the area provided with no a thin film or a non-compact thin film, and further an ordered array of the metal nano particles is formed. The ordered array of the metal nano particles has certain application value on the aspects of Raman detection and plasma regulation and control. In addition, due to the fact that the surface of the generated thin film is provided with functional groups, the method can be applied to selective self assembly, preferential absorption of enzyme and protein and also has good application prospect on the aspects of biological monitoring and sensing.

Description

technical field [0001] The invention belongs to the technical field of ordered microstructures, and in particular relates to a method for preparing thin film ordered microstructures based on reactive ion etching polymers. Background technique [0002] The self-assembly of molecules on the substrate surface refers to the process in which molecules spontaneously form a thermodynamically stable and regularly arranged molecular film on the substrate. The order degree of molecular self-assembly mainly depends on the interaction between molecules and substrates and between molecules. The force of molecular assembly on the substrate mainly includes physical adsorption and chemical adsorption. Physical adsorption refers to the effect that the enthalpy is less than 10kcal / mol, and the interaction force between molecules and the substrate is relatively weak, such as van der Waals force; chemical adsorption refers to thermal The effect of enthalpy greater than 10kcal / mol mainly includ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B82B3/00H01L21/02

Inventor 吕男李宁滕飞封雷吴菲菲

Owner JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com