Electric automatic control system of pneumatic conveying system for raw cement materials

A technology of electric automatic control and pneumatic conveying system, which is applied in the field of electric automatic control system and electric automatic control system of pneumatic conveying technology, can solve the problems of raw material grinding loss, etc., and achieve the effect of reducing operating costs and optimizing control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

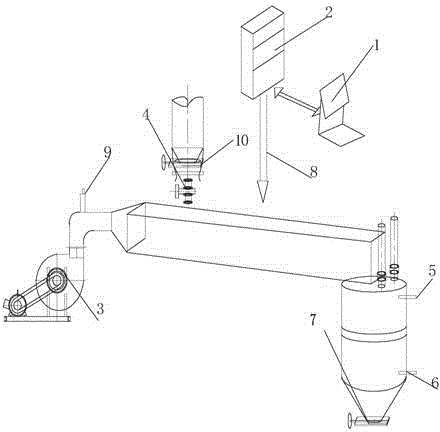

[0010] Example 1 Composition and function of an electrical automatic control system for a cement raw material pneumatic conveying system:

[0011] Electrical automatic control system includes PLC programmable control system 1, industrial computer or DCS system 2, fan motor 3, pneumatic discharge valve 4, high level gauge 5, low level gauge 6, pneumatic plug valve 7, signal transmission cable 8. The weighing sensor 9 and the mass flow meter 10 are composed of the electric automatic control system which is centralized controlled by the PLC programmable control system 1, and its material-gas ratio is 32-35. Equipment regulation. Described industrial control computer or DCS system 2 display the various operations of each control point, monitor drawing respectively with interface; And status; with instrument screen list, system overview screen, alarm overview screen, parameter setting screen. The high-level material level gauge 5 and the low-level material level gauge 6 are ins...

Embodiment 2

[0012] Example 2 The working process of the electric automatic control system of a cement raw meal pneumatic conveying system:

[0013] The industrial computer or DCS system 2 uses the PLC programmable control system 1 to measure the data through the load cell 9 and the mass flow meter 10 according to the material-gas ratio, and sends the material from the hopper to the rotary feeder according to the ratio of the material-gas ratio of 32-35. Cement raw meal is sent to the lower end of the air chute into the bin, and the high-level material level gauge 5 and the low-level material level gauge 6 are installed on the silo for controlling the material level of the silo. The action of the pneumatic flapper valve 7 is used to open and close the outlet of the silo, so as to transport the cement raw meal to the user.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com