Bottle cap discharging water through stirring

A bottle cap and fixed cap technology, applied in the field of liquid packaging bottles, can solve the problems of unsmooth water discharge, difficult production and processing, complex structure, etc., and achieve the effect of smooth water discharge and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

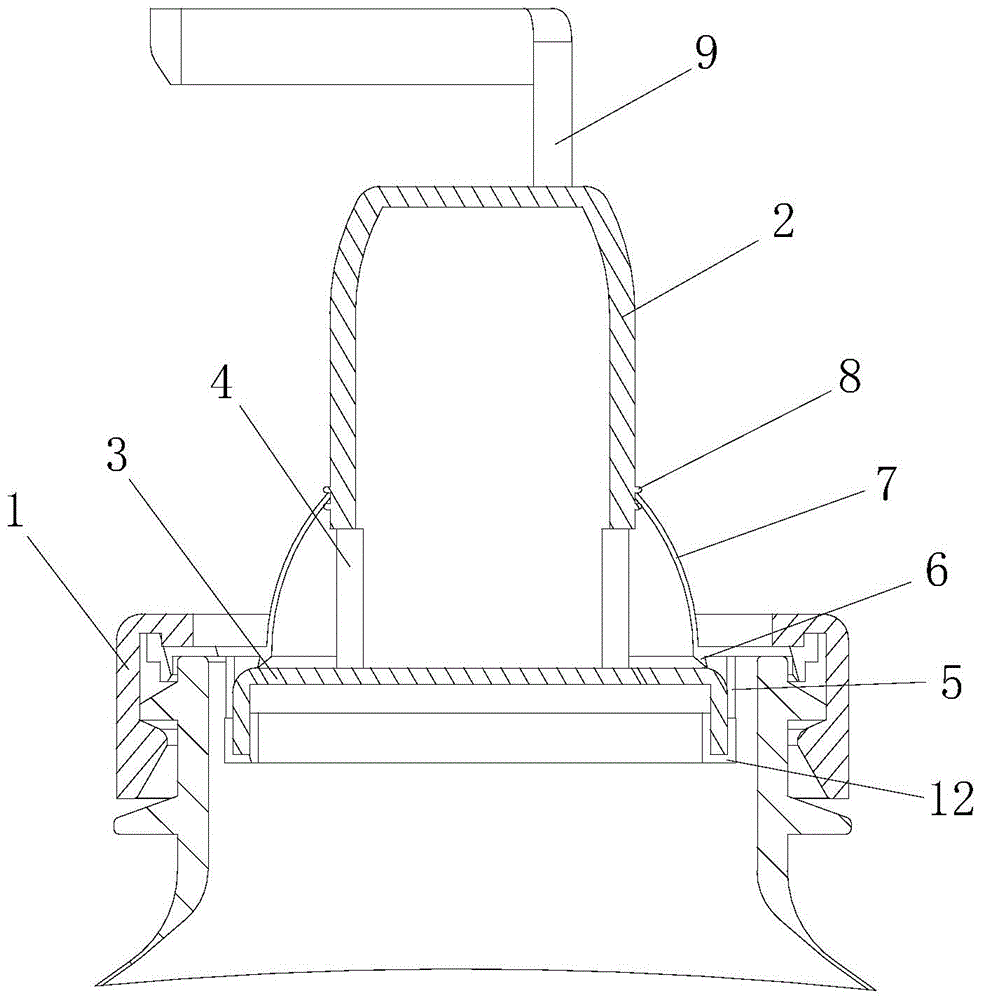

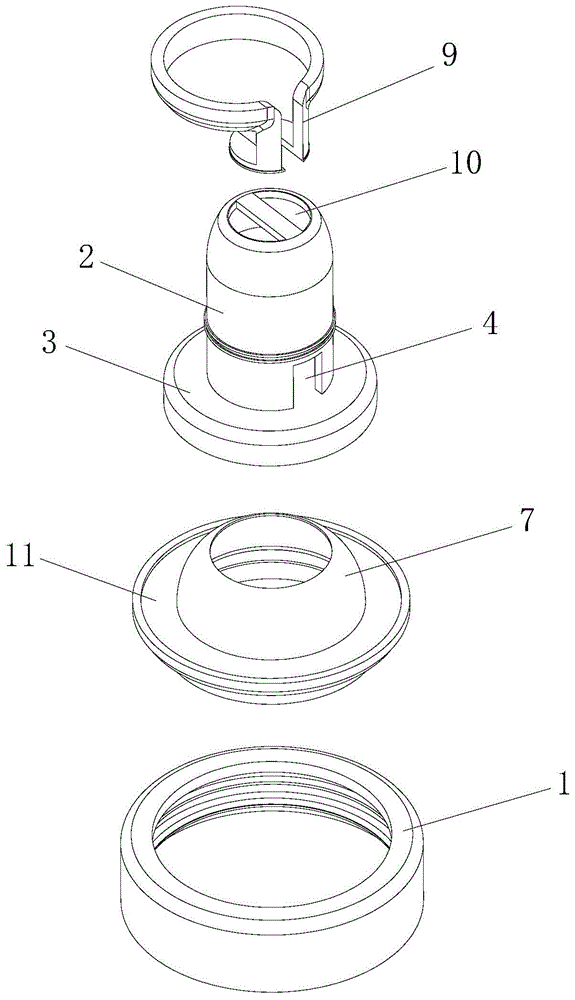

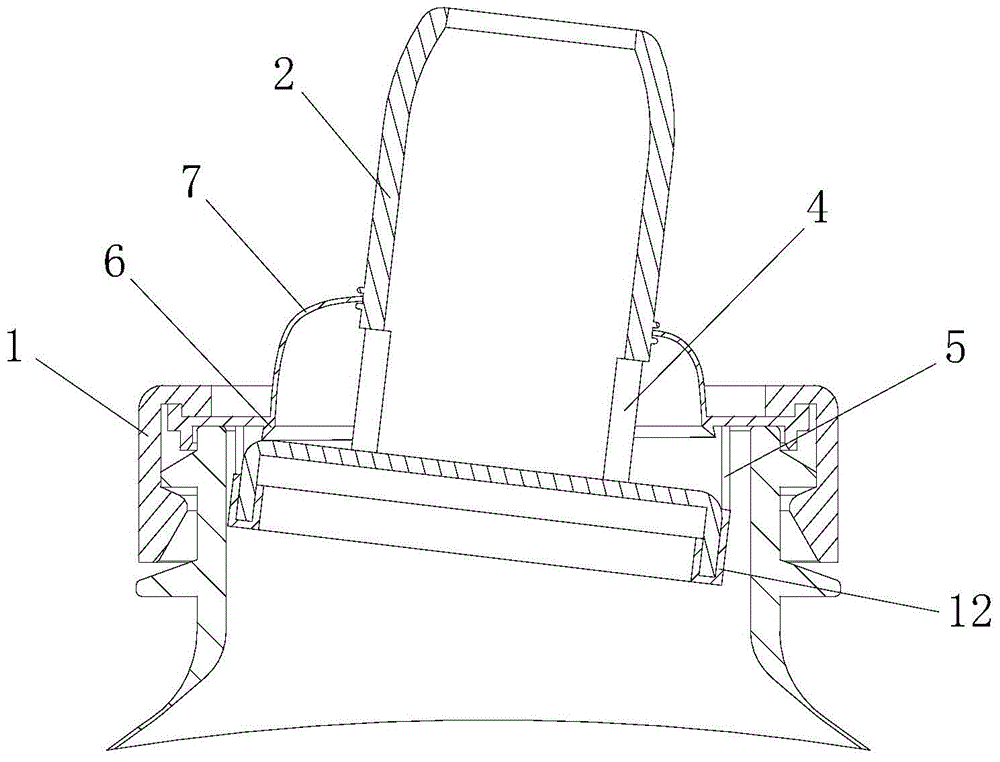

[0014] refer to Figure 1 to Figure 4 , a toggle water bottle cap, including a fixed cap 1, a sealing valve 11 made of elastic material is installed in the fixed cap 1, and the fixed cap 1 and the sealing valve 11 are provided with corresponding suction nozzle insertion holes A suction nozzle 2 with a closed bottom is installed in the nozzle insertion hole, the suction nozzle 2 is made of hard material such as hard plastic, the upper side of the sealing valve 11 is provided with a deformation part 7, and the middle part is provided with a sealing part 6, the lower end is provided with a holding part 12, the lower end of the suction nozzle 2 is provided with a protruding chassis 3, the sealing valve 11 forms a sealing connection with the side wall of the suction nozzle 2, and the sealing part 6 is connected with the suction nozzle 2 The surface of the chassis 3 forms a seal, the lower end of the chassis 3 is fixedly connected to the holding part 12, the suction nozzle 2 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com