Method and device for preparation of superfine spherical metal powder on basis of uniform droplet spray method

A technology of droplet spraying and metal powder, which is applied in the field of spherical microparticle preparation, can solve the problems of poor spreadability, fluidity, and poor sphericity, and achieve the effect of controllable particle size, uniform size, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

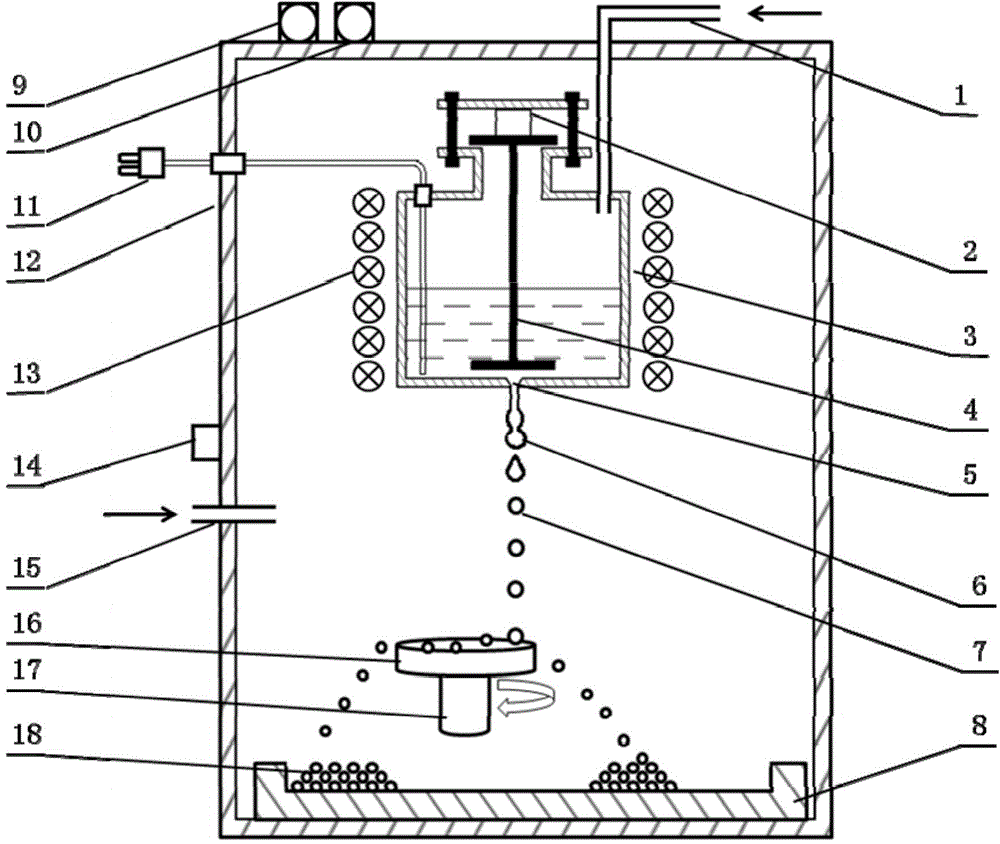

[0042] Specific implementation of batch preparation of Sn63-Pb37 spherical powder for 3D printing:

[0043] Break the Sn63-Pb37 raw material into small pieces, put them into the crucible 3 after ultrasonic vibration, and select the size of the small hole diameter of the nozzle 5 according to the requirements, such as preparing 25 μm-50 μm particles, select the aperture of 0.02mm-1.0mm, such as To prepare 50μm-100μm particles, select a pore size of 1.0mm-2.0mm; the amount of Sn63-Pb37 raw materials should reach 1 / 2-3 / 4 of the crucible 1, such as figure 1 shown;

[0044] Use the mechanical pump 9 to pump the housing 12 and the crucible 3 to a low vacuum of 5 Pa, and then use the diffusion pump 10 to pump the housing 12 and the crucible 3 to a high vacuum of 0.001 Pa; The inert gas argon makes the pressure in the shell 12 and the crucible 3 reach 0.1 MPa;

[0045] Use the induction heater 13 to heat the crucible 3 at a heating temperature of 260° C. to melt the metal material i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com