Preparation method of beta-Ga2O3/SiC nanometer composite material

A nanocomposite material, -ga2o3 technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of complex preparation process, large particle size, long reaction time, etc., and achieve simple device structure and small particle size. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

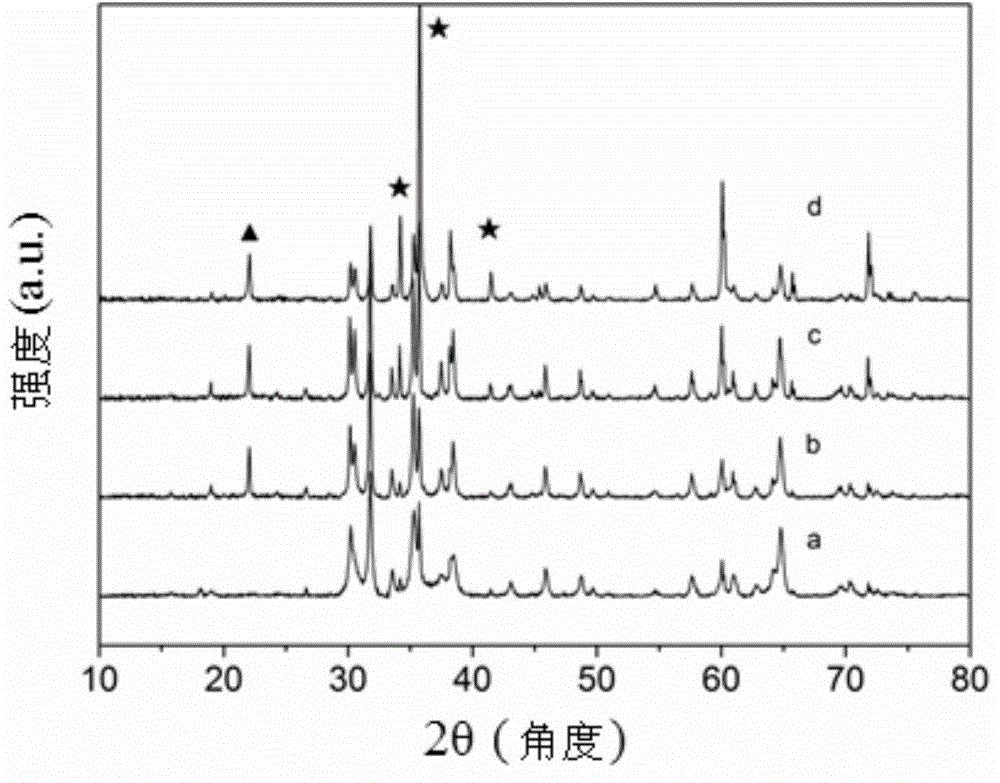

[0038] Specific implementation mode 1: a kind of β-Ga in this implementation mode 2 o 3 The preparation method of SiC nanocomposite material is carried out according to the following steps:

[0039] 1. Add urea into deionized water under magnetic stirring at a stirring speed of 100r / min to 500r / min, and then heat the urea at a temperature of 40 to 100°C and a stirring speed of 100r / min to 500r / min Dissolve completely, then add Ga(NO 3 ) 3 aqueous solution, and stirred at a stirring speed of 100r / min to 500r / min until a colorless and transparent solution is obtained;

[0040] The ratio of the quality of the urea to the volume of the deionized water is 1g: (2-4) mL, the quality of the urea to the Ga(NO 3 ) 3 The volume ratio of the aqueous solution is 1g: (2-4) mL, the Ga(NO 3 ) 3 The concentration of the aqueous solution is 50g / L~70g / L;

[0041] 2. Transfer the colorless and transparent solution obtained in step 1 to a container lined with polytetrafluoroethylene, then ...

specific Embodiment approach 2

[0051] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, urea is added to the deionized water under magnetic stirring at a stirring speed of 200 r / min. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0052] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 1, the temperature is 60° C. and the stirring speed is 200 r / min, and then heated until the urea is completely dissolved. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com