Dimercaptopropanol modified clay mineral material, and preparation method and application thereof

A technology of dimercaptopropanol and clay minerals, applied in chemical instruments and methods, water pollutants, and other chemical processes, can solve problems such as unsatisfactory heavy metal adsorption effects and environmental hazards, and achieve effective utilization, low cost, and Good effect on material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

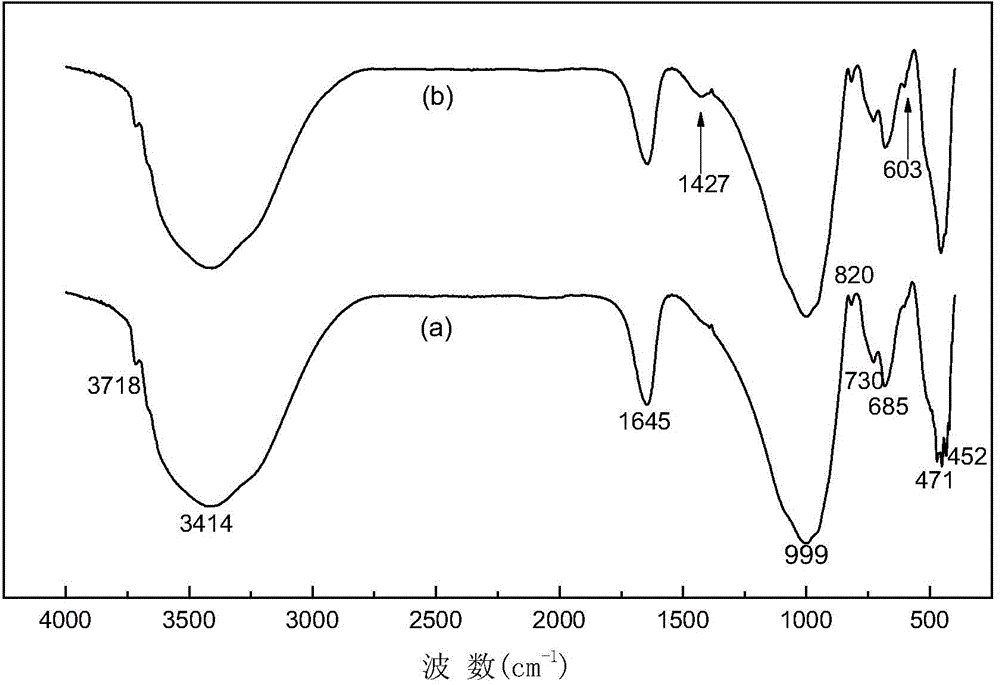

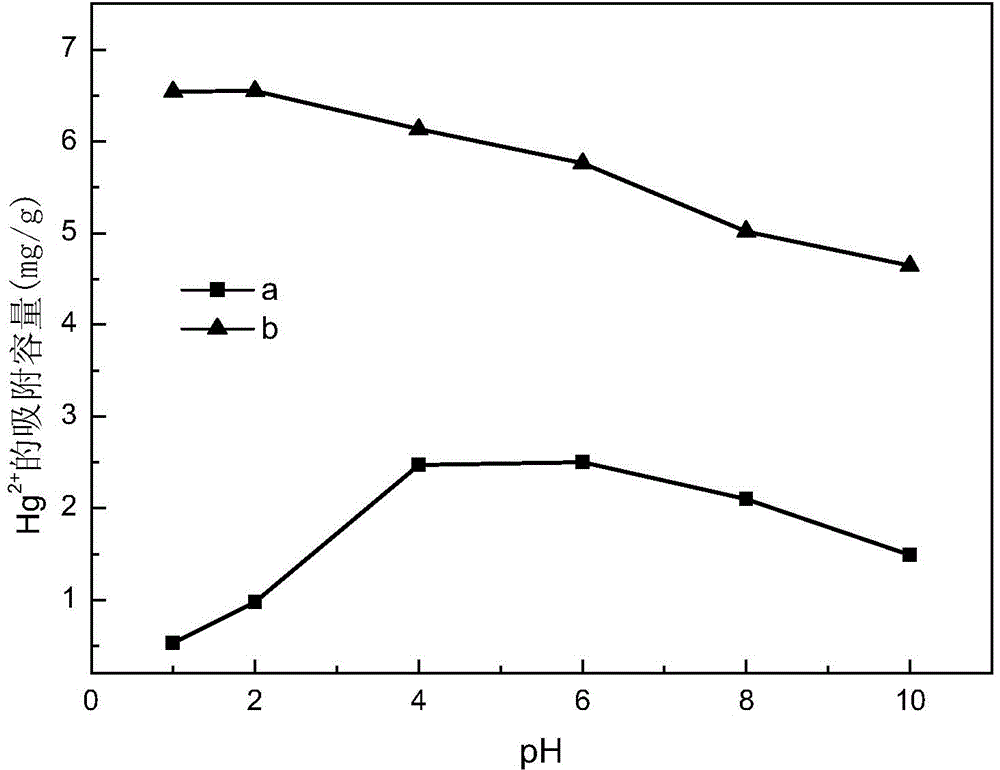

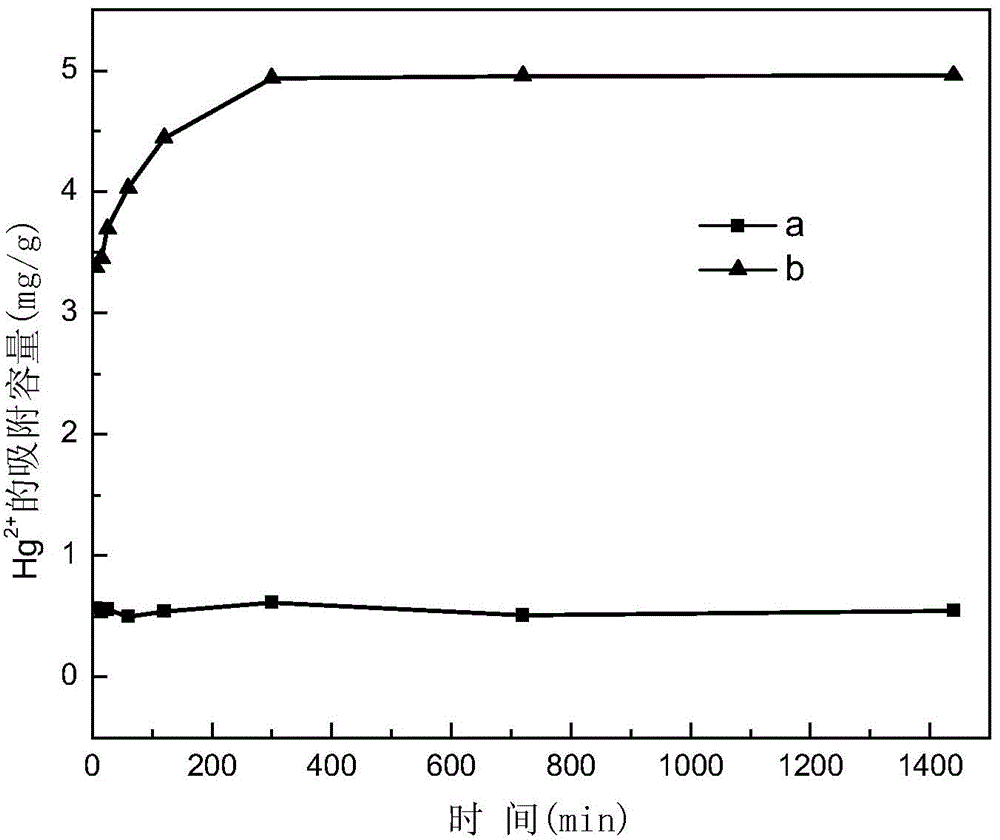

[0036] A dimercaptopropanol modified clay mineral material adopts dimercaptopropanol to modify vermiculite, and the specific steps are as follows:

[0037] (1) take 5g of vermiculite after grinding and pass through 200 mesh sieve processing and join in 100mL absolute ethanol to make the suspension that concentration is 5%, this suspension is ultrasonically treated 10min under 60 ℃ of conditions;

[0038] (2) Press n 二巯基丙醇 : m 蛭石 12.825 mmol dimercaptopropanol was added to the suspension at a ratio of = 2.565 mmol / g, then the pH of the suspension was adjusted to 1 with 0.1 mol / L HCl and NaOH, and refluxed at 80 °C for 20 h to obtain a modified product solution ;

[0039] (3) The obtained modified product solution was placed in a centrifuge at 4000 rpm for 5 min to remove the supernatant, and then the obtained precipitate was washed 6 times with absolute ethanol to make the pH value close to 7, and then vacuum-dried at 60 °C for 24 h , and grinded through a 200-mesh sieve to ...

Embodiment 2

[0044] A dimercaptopropanol modified clay mineral material adopts dimercaptopropanol to modify vermiculite, and the specific steps are as follows:

[0045] (1) take by weighing 5g vermiculite after grinding and pass through 200 mesh sieve processing and join in 100mL absolute ethanol to make the suspension that concentration is 5%, this suspension is ultrasonically treated 10min under 55 ℃ of conditions;

[0046] (2) Press n 二巯基丙醇 : m 蛭石Add 12.825 mmol dimercaptopropanol to the suspension at a ratio of =2.565 mmol / g, then adjust the pH of the suspension to 4 with 0.1 mol / L HCl and NaOH, and reflux at 90 °C for 20 h to obtain a modified product solution ;

[0047] (3) The obtained modified product solution was placed in a centrifuge at 4000 rpm for 10 min to remove the supernatant, and then the obtained precipitate was washed 6 times with absolute ethanol to make the pH value close to 7, and then vacuum-dried at 65 °C for 24 h , and grinded through a 200-mesh sieve to obtain...

Embodiment 3

[0051] A dimercaptopropanol modified clay mineral material adopts dimercaptopropanol to modify vermiculite, and the specific steps are as follows:

[0052] (1) take 5g of vermiculite after grinding and pass through 200 mesh sieve processing and join in 100mL absolute ethanol to make the suspension that concentration is 5%, this suspension is ultrasonically treated 10min under 60 ℃ of conditions;

[0053] (2) Press n 二巯基丙醇 : m 蛭石 Add 4.275mmol dimercaptopropanol to the suspension at a ratio of =0.855mmol / g, then adjust the pH of the suspension to 1 with 0.1mol / L HCl and NaOH, and reflux at 80°C for 20h to obtain a modified product solution ;

[0054] (3) The obtained modified product solution was placed in a centrifuge at 4000 rpm for 5 min to remove the supernatant, and then the obtained precipitate was washed 6 times with absolute ethanol to make the pH value close to 7, and then vacuum-dried at 60 °C for 24 h , and grinded through a 200-mesh sieve to obtain dimercaptoprop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com