Antibacterial composite nanofiltration membrane with high salt rejection rate and preparation method of antibacterial composite nanofiltration membrane

A composite nanofiltration membrane, high-cut technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as troublesome use, inability to remove bacteria and viruses, and achieve simple experimental process and enhanced antibacterial performance , The effect of increasing the salt interception rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

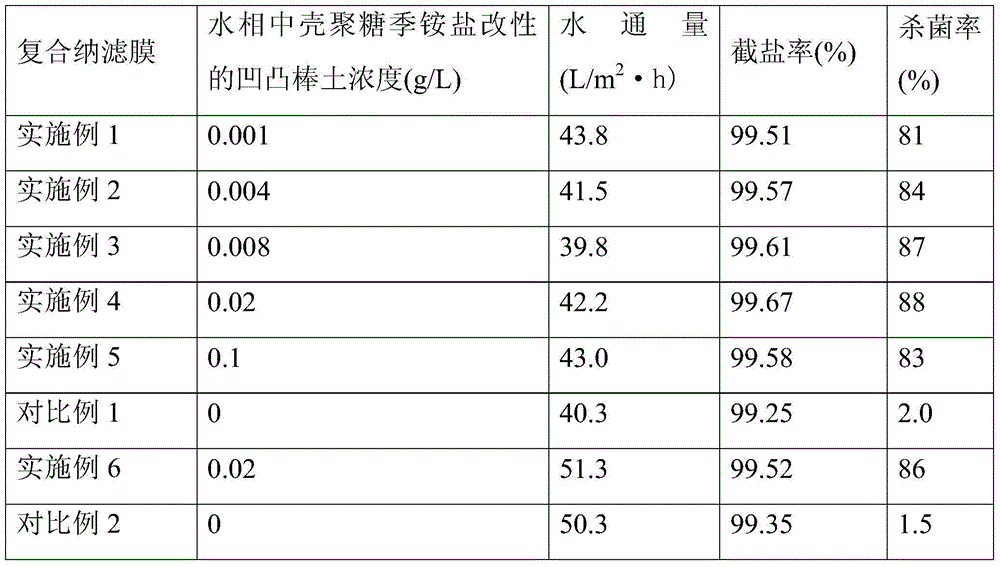

Embodiment 1

[0068] The specific purification steps of the attapulgite used in the present embodiment are as follows:

[0069] Prepare an attapulgite aqueous solution with a mass concentration of 10%, add a dispersant sodium hexametaphosphate whose mass is 10% of the attapulgite mass, mechanically stir for 30 minutes, ultrasonically treat for 30 minutes, and centrifuge at 2000r / min ; The supernatant was discarded and dried in an oven at 80°C.

[0070] The specific steps of the attapulgite modification after the purification in the present embodiment are as follows:

[0071] Prepare a purified attapulgite aqueous solution with a mass concentration of 10%, add chitosan quaternary ammonium salt powder with a mass of 20% of the mass of attapulgite; at 70°C, magnetically stir for 2 hours; the above reaction solution is passed through After centrifugation (2000r / min) for a certain period of time, the supernatant was discarded; the modified attapulgite was dried in an oven at 80°C, cooled and gr...

Embodiment 2

[0075] Except that the concentration of the attapulgite modified by chitosan quaternary ammonium salt is changed to 0.004g / L in the water phase added again on the polyamide layer generated, other processing steps and test conditions are all the same as in Example 1, The test results of the prepared composite nanofiltration membrane are listed in Table 1.

Embodiment 3

[0077] Except that the concentration of the attapulgite modified by chitosan quaternary ammonium salt is changed to 0.008g / L in the aqueous phase added again on the polyamide layer generated, other processing steps and test conditions are all the same as in Example 1, The test results of the prepared composite nanofiltration membrane are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com