Process device of coke oven fume denitrification, desulfuration and reheating system

A technology for a process device and a flue gas reheater, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of system corrosion, low denitration and desulfurization efficiency, and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

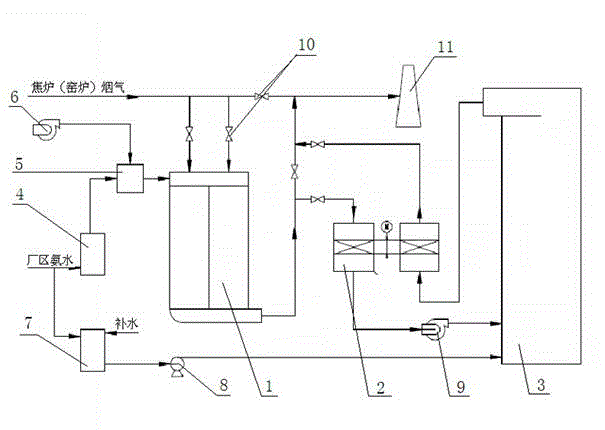

[0020] The flue gas from the coke oven first enters the SCR denitrification reactor 1 for denitrification, and the hot flue gas after denitrification enters the GGH flue gas reheater 2 and the wet flue gas after desulfurization in the desulfurization tower 3 for heat exchange. After -350°C drops to 150-160°C, it is pressurized by booster fan 9 and then enters desulfurization tower 3 for desulfurization. The wet flue gas at the outlet of desulfurization tower 3 enters the GGH flue gas reheater and changes heat from 70-80°C to about 160°C. The gas enters the chimney 11 for discharge. The flue gas of the whole system is switched through the flue gas switching valve 10, that is, when desulfurization maintenance or power failure occurs, the flue gas after denitration is directly discharged into the chimney 11 through the switching valve; when the SCR denitrification reactor is poisoned by flue gas tar, etc. The on-line reproduction is switched by the flue gas switching valve 10 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com