Preparation method of melatonin controlled-release composition and preparation method of melatonin controlled-release tablet

A sustained-release composition, the technology of melatonin, applied in the direction of non-active ingredient medical preparations, drug delivery, pharmaceutical formulations, etc., can solve the unstable curative effect of melatonin sustained-release tablets, intermediates or sustained-release Uneven tablet content, small drug content, etc., to improve the phenomenon of easy adhesion to the inner wall of the metal, prevent uneven content of wet particles, and improve content uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

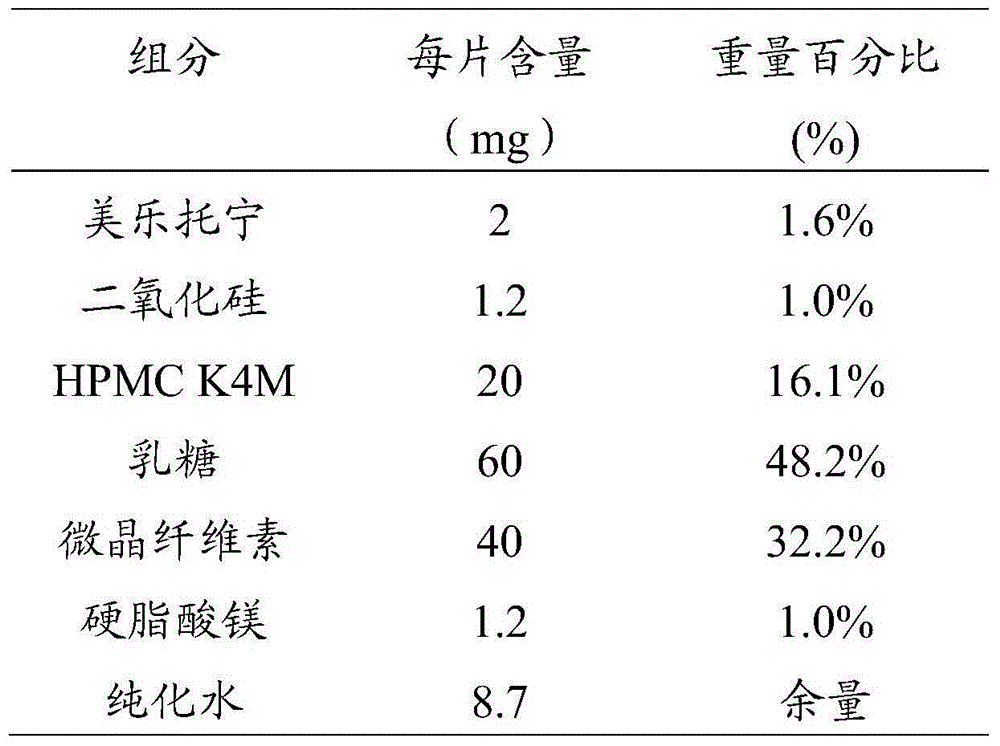

[0048] The preparation of embodiment 1 Meiletonin sustained-release tablet

[0049]

[0050] Preparation method: weigh each raw and auxiliary material according to the prescription amount in batches of 10,000 tablets, mix melatonin and silicon dioxide evenly, sieve, and set aside. According to the order of lactose, microcrystalline cellulose, the mixture of melatonin and silicon dioxide, and HPMC K4M, the raw and auxiliary materials are added to the 4L pot of the Mini-CG high-speed mixing granulator, and the bottom slurry and side slurry are opened. Set the rotation speed of the bottom slurry to 400rpm, the rotation speed of the side slurry to 800rpm, and the protective air pressure of the bottom slurry and the side slurry are both 0.05MPa, and mix them. When mixing for 5min, 10min, and 15min respectively, in the upper, middle and lower three stages of the 4L granulation pot Samples were taken at each location, and a total of 9 samples were obtained, and the content uniform...

Embodiment 2

[0055] The preparation of embodiment 2 Meiletonin sustained-release tablets

[0056]

[0057] Preparation method: weigh each raw and auxiliary material according to the prescription amount in batches of 10,000 tablets, sieve and mix melatonin and silicon dioxide evenly, and set aside. According to the order of calcium hydrogen phosphate, microcrystalline cellulose, the mixture of melatonin and silicon dioxide, and HPMC K15M, the raw and auxiliary materials are sequentially added to the 4L pot of the Mini-CG high-speed mixing granulator, and the bottom pulp and side pulp are opened. Slurry, set the rotation speed of the bottom slurry to 400rpm, the rotation speed of the side slurry to 800rpm, the protection air pressure of the bottom slurry and the side slurry is 0.05MPa, mix, and when mixing for 5min, 10min, and 15min respectively, in the upper, middle, and The next three positions were sampled respectively, and a total of 9 samples were obtained, and the content uniformity...

Embodiment 3

[0062] The preparation of embodiment 3 Meiletonin sustained-release tablets

[0063]

[0064] Preparation method: weigh each raw and auxiliary material according to the prescription amount in batches of 10,000 tablets, mix melatonin and kaolin evenly, sieve, and set aside. According to the order of calcium hydrogen phosphate, mannitol, mixture of melatonin and kaolin, and sodium alginate, add the raw and auxiliary materials into the 4L pot of the Mini-CG high-speed mixing granulator, open the bottom slurry and side slurry, and set The rotation speed of the bottom slurry is 400rpm, the rotation speed of the side slurry is 800rpm, and the protection pressure of the bottom slurry and the side slurry are both 0.05MPa. Mix them. When mixing for 5min, 10min, and 15min, respectively, in the upper, middle, and lower parts of the 4L granulation pot, Samples were taken at each location, and a total of 9 samples were obtained to measure the content uniformity. After mixing, add ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com