Multi-redundant metal framework platinum resistor temperature sensing element and manufacturing method thereof

A metal skeleton and temperature-sensing element technology, which is applied to thermometers, thermometers, and electrical devices that use directly heat-sensitive electric/magnetic elements, can solve problems such as low structural strength, large thermal conductivity, and difficult machining. Achieve the effect of increasing the medium conduction area, increasing the thermal conductivity, and reducing the conduction thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

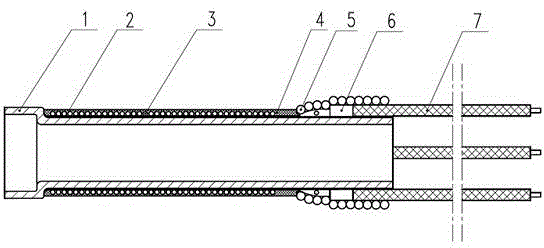

[0016] A redundant metal skeleton platinum resistance temperature sensing element, such as figure 1 As shown, it includes a hollow metal frame 1, and the periphery of the metal frame 1 is coated with Al 2 o 3 Insulating coating 2, one end of the metal frame 1 is trumpet-shaped, and the periphery of the other end has a plurality of silver lugs 6 uniformly arranged in the circumferential direction. The silver lugs 6 are connected with lead wires 7 and are surrounded by alkali-free glass fiber ropes. 5. A platinum wire 3 connected to a silver lug 6 is wound between the two ends of the metal skeleton 1 , and the periphery of the platinum wire 3 and the alkali-free glass fiber 5 is coated with a high-temperature resistant insulating sealing coating 4 .

[0017] The following is a method for manufacturing a redundant metal skeleton platinum resistance temperature sensing element of the present invention, which specifically includes the following steps:

[0018] a. Metal skeleton ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com