Application of in-situ combustion flue gas to oil deposit exploitation and system

A technology of burning oil beds and oil reservoirs, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of increased oil production operation costs, multiple ground spaces, etc., to improve single well oil production, surface Air quality improvement, enhanced distillation effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

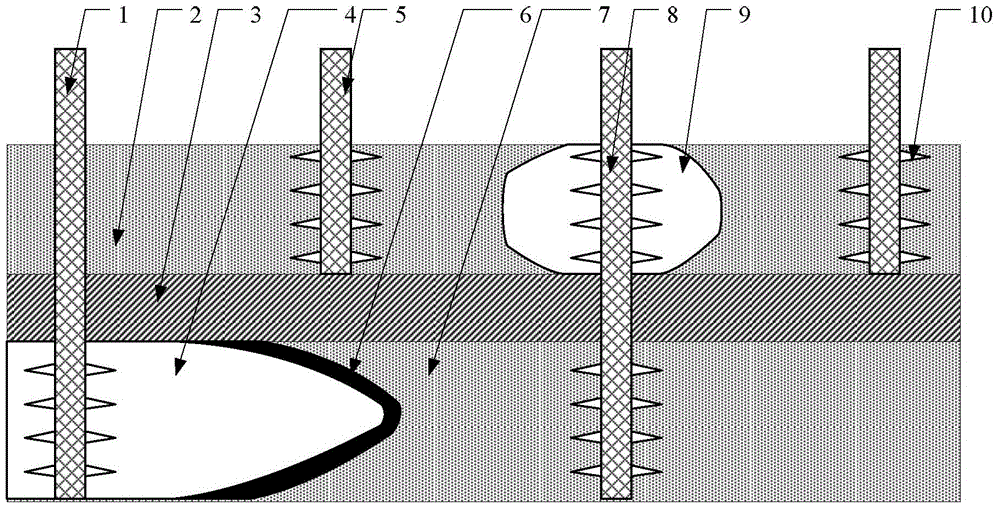

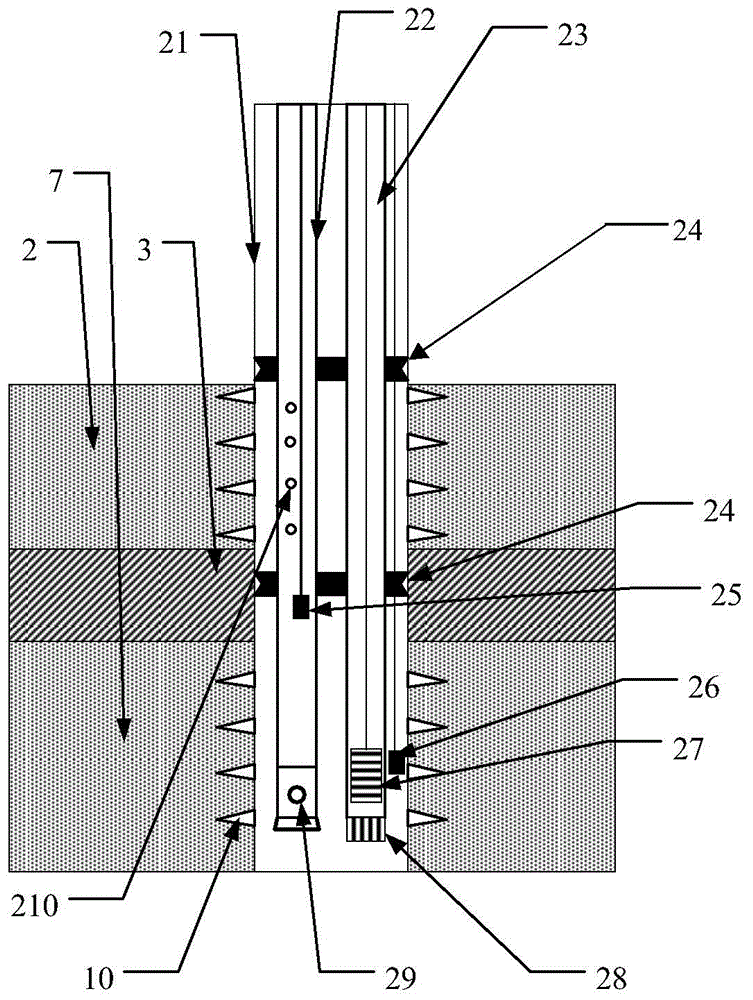

[0061] Attached below figure 1 The method for reinjecting flue gas from the combustion oil layer of the present invention is described in detail. In the figure, the oil layers 2 and 7 are divided into two sets of independent well patterns by the interlayer 3. The interlayer is well sealed, and the flue gas cannot break through the interlayer and rise to the upper part of the interlayer. The upper and lower wells are developed with two sets of well patterns respectively. The oil layer above the interlayer is developed by steam injection technology, and the oil layer below the interlayer is developed by fire technology. Fire-fired gas injection vertical well 1 is an air injection vertical well, through the ground high-pressure air injection pump 3 Inject air into oil layer 7 at / d speed. After air injection into the oil layer 7, the pressure is 4 MPa, and the combustion zone 6 advances toward the burning production well 8 at a rate of 3-10 cm / d per day. Behind the combustion z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com