Fibre cutting device for asphalt-macadam synchronous sealing vehicle or equipment

A technology of asphalt gravel and cutting device, which is applied to roads, road repairs, roads, etc. It can solve the problems of being unable to satisfy the simultaneous spraying of asphalt, and can only spray asphalt and stones, and achieve simple structure, easy operation, and reliability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

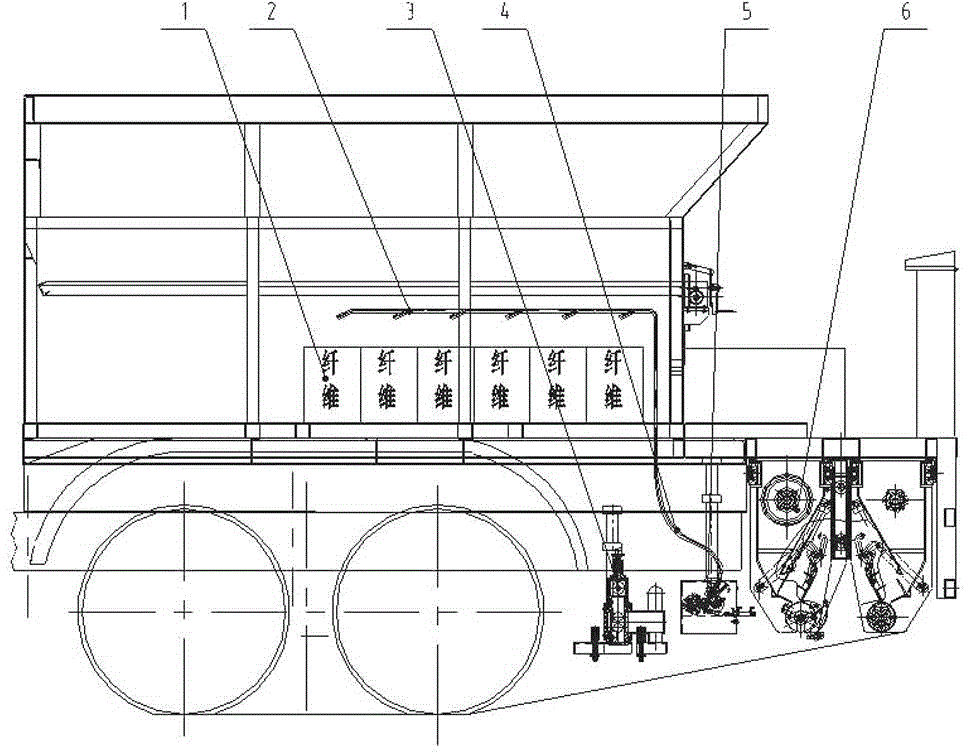

[0013] Example: figure 1 , 2 As shown, an asphalt, gravel and fiber sealing vehicle, it realizes the three-in-one simultaneous spreading (spreading) of asphalt, gravel and fiber through the asphalt spraying rod 11, the fiber cutting assembly 4 and the stone spreading device 12 ; It can also be sprinkled (scattered) alone.

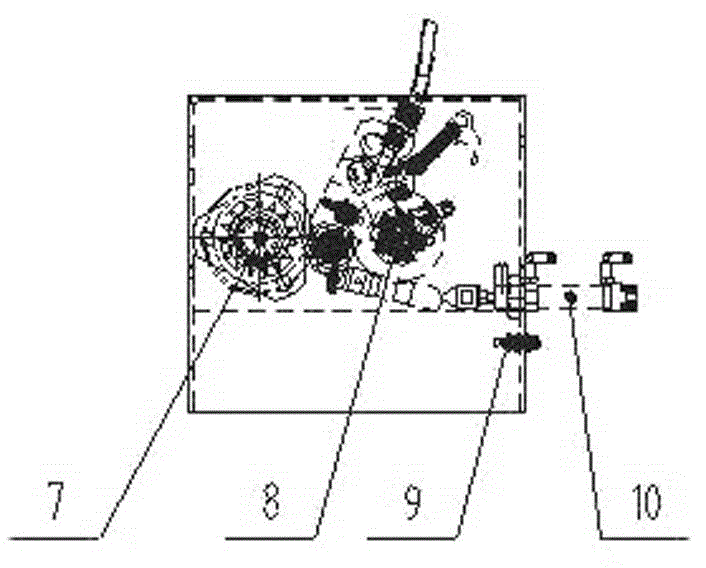

[0014] The fiber raw material 2 enters the fiber cutting assembly 4 through the steel pipe channel 3 and the hose channel 5; the hydraulic motor 7 drives the driving wheel 8 to rotate, and drives the rotary cutting tool 6 to rotate through friction, and cuts the fiber during the tool rotation. The high-pressure air passes through the blowing nozzle 9 to evenly blow the cut fibers to the construction road surface. By controlling the cutter switch cylinder 10, the switch of the cutter is realized, thereby realizing the adjustment of the fiber spreading width.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com