Toxigenic medium of AFG2, and AFG2 toxigenic fermentation method of Aspergillus parasiticus

A technology of toxin-producing medium and Aspergillus parasiticus, applied in the field of fermentation engineering, can solve the problems of long time consumption, unevenness, and low AFG2 concentration, and achieve the effects of shortened culture time, high spore vigor, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

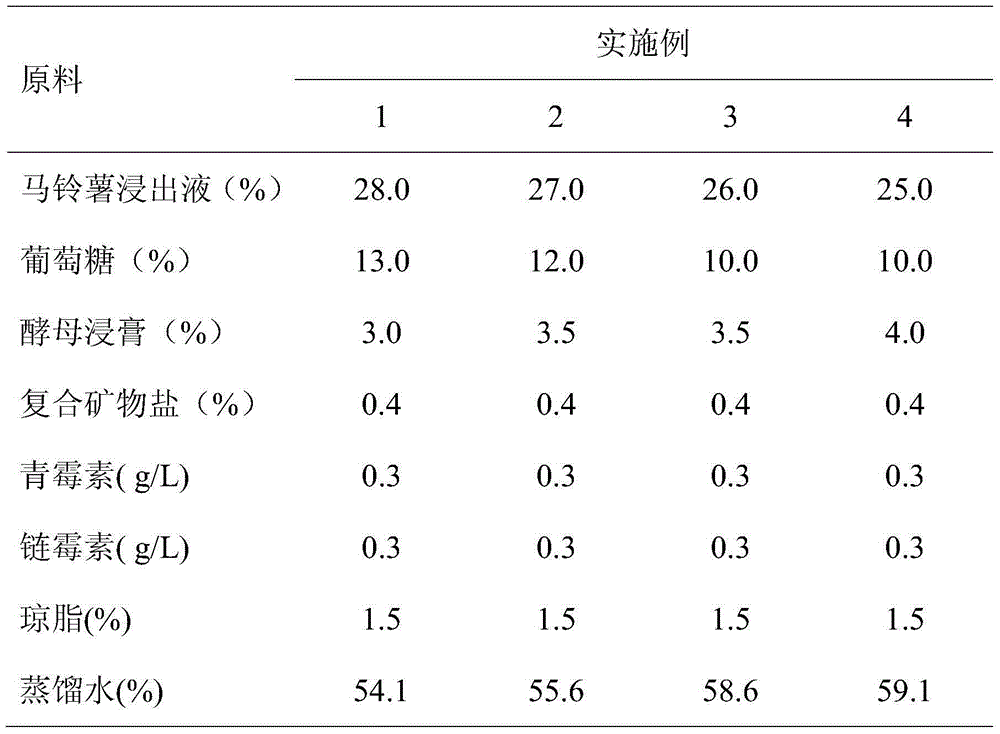

[0018] The preparation of embodiment 1-4 enrichment culture medium

[0019] A bacterium enrichment medium for Aspergillus parasiticus strains, after mixing the components shown in Table 1, adjust the pH value of the bacterium enrichment medium to 5.5-7.0 with hydrochloric acid and sodium hydroxide solution.

[0020] Table 1

[0021]

Embodiment 5-8

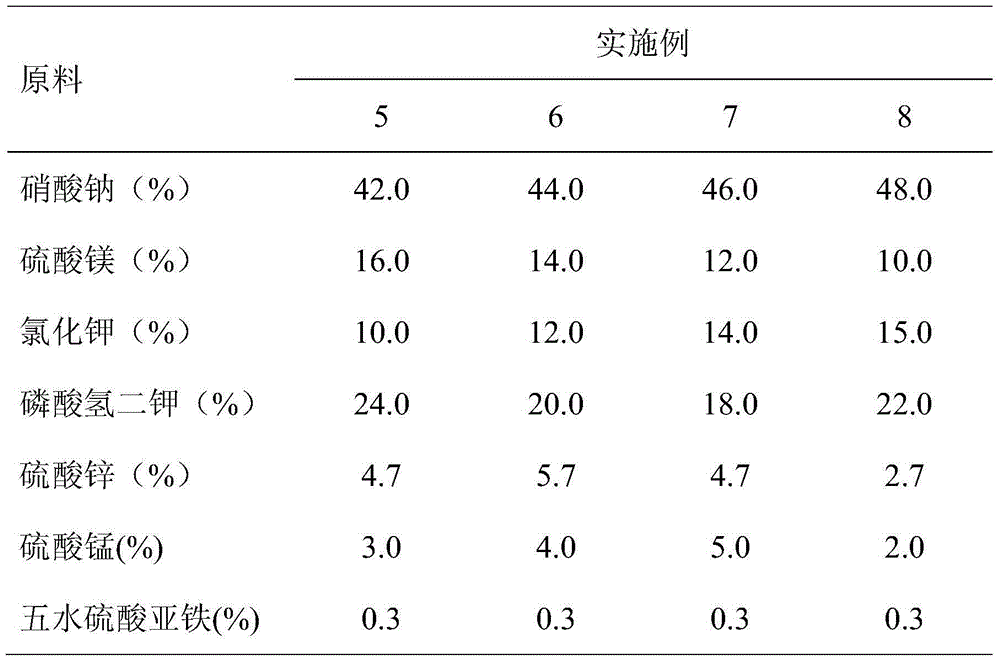

[0022] The preparation of embodiment 5-8 compound mineral salt

[0023] Take sodium nitrate, magnesium sulfate, potassium chloride, dipotassium hydrogen phosphate, zinc sulfate, manganese sulfate and ferrous sulfate pentahydrate according to the ratio in Table 2, mix the above mineral salts evenly, and pulverize them through an 80-mesh sieve , mixed again for later use, to obtain the compound mineral salts described in the enrichment medium and solid fermentation medium.

[0024] Table 2

[0025]

[0026] Now take the compound mineral salt formula of embodiment 6 and the bacterium enrichment medium formula of embodiment 2 as examples, prepare 100g compound mineral salt and 1L bacterium enrichment medium.

[0027] Composite mineral salt (100g): take by weighing 44.0g sodium nitrate, 14.0g magnesium sulfate, 12.0g potassium chloride, 20.0g dipotassium hydrogen phosphate, 5.7g zinc sulfate, 4.0g manganese sulfate, 0.3g pentahydrate with analytical balance respectively Mix fe...

Embodiment 9-12

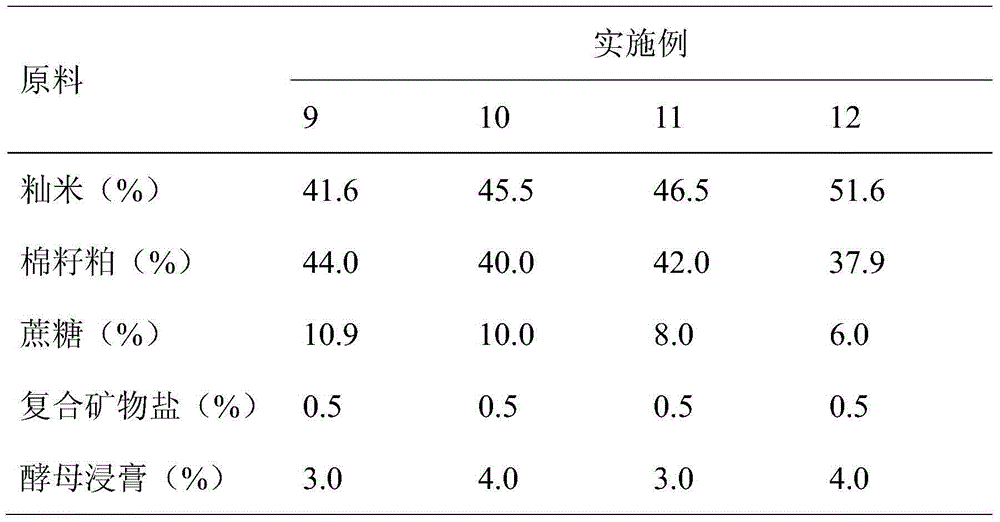

[0032] The preparation of embodiment 9-12 Aspergillus parasiticus solid fermentation medium

[0033] According to the formula in Table 3, prepare the required solid fermentation medium.

[0034] table 3

[0035]

[0036] Raw material preparation: crush the indica rice and cottonseed meal, and it is required to pass through a 20-mesh standard sampling sieve, but not through a 40-mesh standard sampling sieve, that is, the particle size is between 20-40 mesh.

[0037] Now take the compound mineral salt formula of embodiment 6 and the component of embodiment 10 as example, prepare 100g compound mineral salt and 1L bacteria enrichment medium.

[0038] Composite mineral salt (100g): take by weighing 44.0g sodium nitrate, 14.0g magnesium sulfate, 12.0g potassium chloride, 20.0g dipotassium hydrogen phosphate, 5.7g zinc sulfate, 4.0g manganese sulfate, 0.3g pentahydrate with analytical balance respectively Mix ferrous sulfate in a beaker evenly, then put all the mixed mineral salts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com