Method for improving fermentation efficiency of anaerobic gas feeding microorganisms

A technology for microbial fermentation and microorganisms, which is applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as low efficiency, and achieve the effect of improving efficiency and gas-liquid mass transfer rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

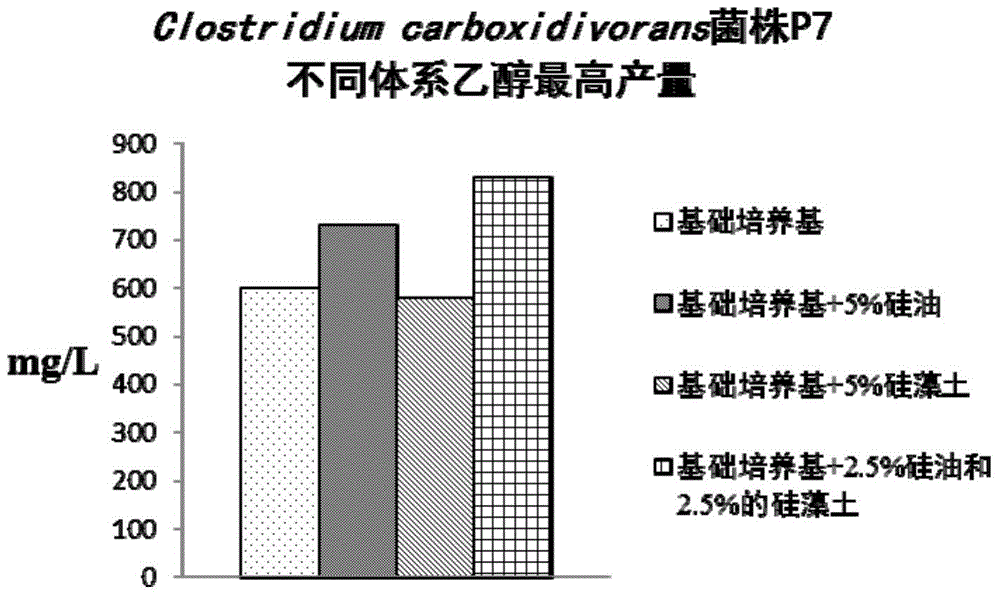

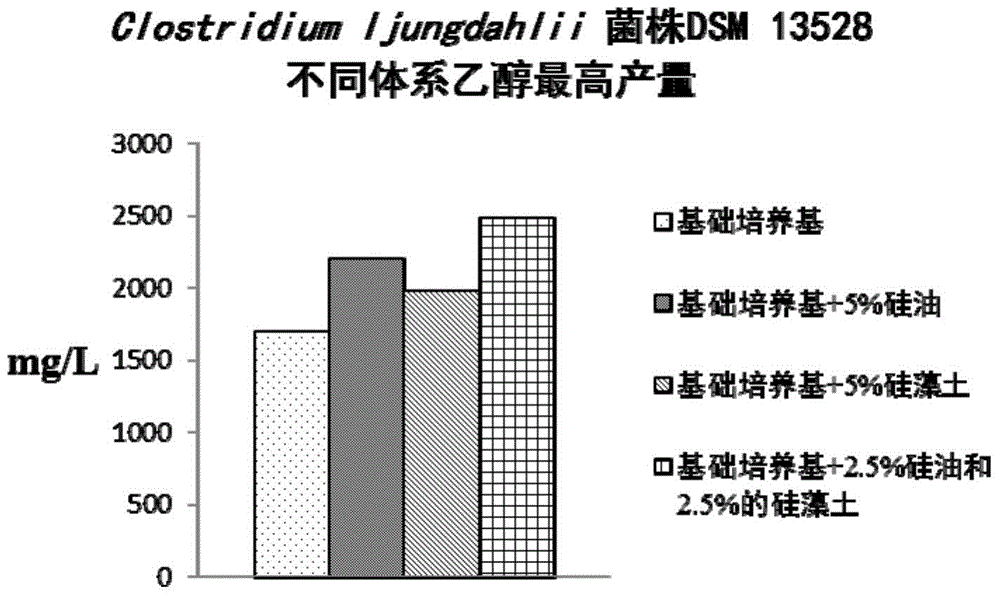

[0024] Shaking culture at constant temperature: add 2ml mineral solution stock, 0.05g yeast extract and 0.5g morpholine ethanesulfonic acid, and a certain proportion of diatomaceous earth and / or simethicone to 100ml system, 5ml reducing agent stock , filled with 99.999% nitrogen at a rate of 2 L / min for 5 minutes, sealed, and sterilized at 121 degrees for 20 minutes. After sterilization, cool to about 40 degrees, and then add 0.1ml of trace element storage solution to complete the construction of the culture system. Insert 10ml of Clostridium carboxidivorans bacterial strain P7 or Clostridium ljungdahlii bacterial strain DSM 13528 culture solution cultivated to the logarithmic growth phase, then continuously feed simulated syngas (gas composition: 50% CO, 35% CO 2 , 15%H 2 ) to balance for 5 minutes, pressurize to 0.6bar to seal. Shake culture at 37 degrees and 180 rpm, and take samples at regular intervals for fermentation product detection.

[0025] The constructed cultur...

Embodiment 2

[0030] Embodiment 2: continuous aeration and stirring culture

[0031] In the continuous aerated culture system of Clostridium carboxidivorans strain P7 with added substances, the production of acetic acid was significantly higher than that of the culture system composed of the basic medium, the basic medium system, the basic medium system + 5% silicone oil system and the basic medium system + The content of acetic acid in the 5% diatomite system has reached 9.8g / L, 28g / L and 19g / L ( Figure 5 ). Compared with the basal culture system, the yield of the latter two systems increased by 185% and 93.9% respectively. Compared with the shaking culture system, the continuous aeration and stirring culture method can give full play to the advantages of this culture system.

Embodiment 3

[0032] Example 3: Effects of Different Proportions of Additives on the Alcohol Production Effect of Fermentation System

[0033] 1%, 2%, 3%, 4% and 5% simethicone oil were added to the basal medium of Clostridium carboxidivorans strain P7 for fermentation, and the effect of butanol fermentation was detected. It is found that different proportions of additives will increase the butanol production of the system to varying degrees, and the butanol production of the fermentation system with the additive concentration from low to high is 70mg / L, 82mg / L, 97mg / L, 131mg / L , 157mg / L and 168mg / L ( Image 6 ), with the increase of the addition ratio, the butanol yield also showed a significant increase.

[0034]Clostridium ljungdahlii strain DSM 13528 was added 1%, 2%, 3%, 4% and 5% diatomaceous earth to the basal medium for fermentation, and the ethanol fermentation effect was detected. It is found that different proportions of additives will increase the ethanol production of the sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com