Trichoderma viride fermented extract improves the method of alcoholic fermentation yield

A technology of Trichoderma viride and alcohol fermentation, applied in microorganism-based methods, biochemical equipment and methods, fermentation and other directions, can solve the problems of limited product use effect and high production cost, achieve obvious use effect, reduce production cost and price cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

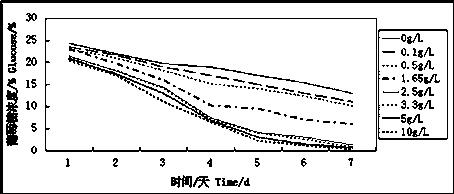

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

[0019] As shown in the figure: the method that a kind of Trichoderma viride fermented extract of the present invention improves alcohol fermentation output comprises the following steps at least:

[0020] (1) Solid-state fermentation with straw as raw material

[0021] Add straw powder into the fermentation tank, then add water and ammonium nitrate, and stir well, then insert Trichoderma viride CGMCC3.6619, so that the bacteria and straw powder can fully contact; continue to cultivate in a constant temperature room at 28°C for one month, after fermentation Dried to obtain the fermentation substrate for subsequent use;

[0022] (2) Extraction and purification of extract alcohol

[0023] Use 3.5% NaOH solution to extract the dried fermentation substrate obtained in step (1), filter it in a constant temperature water bath at 60°C for 1 hour, and then concentrate the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com