Method for producing biodiesel and feed by use of acorn vinasse

A biodiesel, distiller's grains technology, applied in animal feed, biofuel, animal feed, etc., can solve the problems of uncompetitive nutritional value and price, short storage time, difficult to market, etc., and achieve good product marketization and operation. Convenience and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

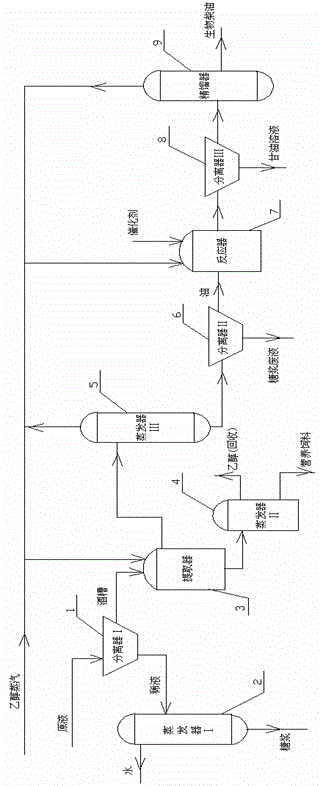

[0022] Put 100kg of raw liquid into separator I1 for separation, and separate to obtain 8kg of distiller's grains and 92kg of thin liquid, and the thin liquid enters evaporator I2 to evaporate water to obtain syrup; send distiller's grains and ethanol steam into the extractor, and extract 6 kg of distiller's grains at a temperature of 75°C Hours later, the extract and roughage were obtained. After the roughage was evaporated by the evaporator I4, about 2.94kg of nutritious feed was obtained. The protein content of the nutritious feed was 39.7% (the shelf life was 12 months); the extract was evaporated in the evaporator III5, and about 5kg of concentrated feed was obtained. Then the concentrated liquid enters the separator Ⅱ6 and stratifies at room temperature, and about 1.7kg of oil in the upper layer is separated, and the oil, ethanol vapor and sulfuric acid catalyst (8.5g) of 0.5% oil quality are carried out in the reactor for transesterification. React at a temperature of 15...

Embodiment 2

[0024] Put 100kg of raw liquid into separator Ⅰ1 for separation, and separate to obtain 8kg of distiller's grains and 92kg of thin liquid, and the thin liquid enters evaporator I2 to evaporate water to obtain syrup; send distiller's grains and ethanol steam into the extractor, and extract 7 Hours later, the extract and roughage were obtained, and the roughage was evaporated by the evaporator I4 to obtain 2.76kg of nutritious feed, and the protein content of the nutritious feed was 40.1% (the shelf life was 12 months); the extract was evaporated into the evaporator III5 to obtain 5.2kg of concentrated liquid , and then the concentrated liquid enters the separator Ⅱ6 to separate layers at room temperature, and about 1.78kg of oil in the upper layer is separated, and the oil, ethanol vapor and 0.8% oil quality NaOH catalyst (14.24g) are transesterified in the reactor, React at a temperature of 160°C for 8 hours, and then the product enters the separator III 8 and stands at room te...

Embodiment 3

[0026] Put 100kg of raw liquid into separator I1 for separation, and separate to obtain 8kg of distiller's grains and 92kg of thin liquid, and the thin liquid enters evaporator I2 to evaporate water to obtain syrup; send distiller's grains and ethanol steam into the extractor, and extract 6 kg of distiller's grains at a temperature of 90°C Hours later, the extract and roughage were obtained. After the roughage was evaporated by evaporator I4, 2.72kg of nutritious feed was obtained. The protein content of the nutritious feed was 39% (shelf life was 13 months); the extract was evaporated in evaporator III5 to obtain 5.23kg of concentrated liquid , and then the concentrated solution enters the separator II6 to separate layers at room temperature, and about 1.8kg of oil in the upper layer is separated, and the oil, ethanol vapor and 1% oil quality KOH catalyst (18g) carry out transesterification in the reactor. The reaction temperature was 170°C for 8 hours, and then the product en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com