Industrial synthesis method of high-thermal-stability terminated polysulfone resin

A high thermal stability, polysulfone resin technology, applied in the field of polymer materials, can solve the problems of increasing recycling equipment, restricting the quality of polysulfone, and high equipment costs, and achieving the effects of shortening reaction time, saving procurement costs, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

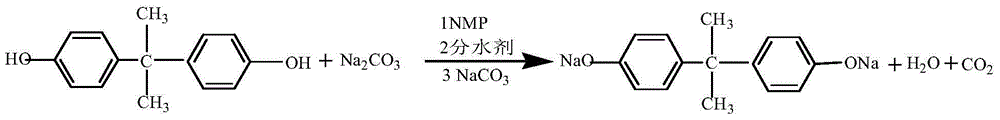

Method used

Image

Examples

Embodiment 1

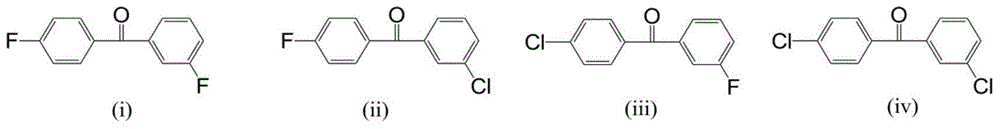

[0029] In a 200-liter stainless steel reaction kettle equipped with a nitrogen pipe, a condensing water separator and a high-efficiency stirrer, first add 100.00KG N-methylpyrrolidone, then start stirring and raise the temperature to 80°C, and then add 23.30KG 4,4'- Dichlorodiphenyl sulfone, 18.67KG bisphenol A, after the monomers are completely dissolved, add 9.50KG sodium carbonate to the system when the temperature rises to 100°C, then add 9.0 liters of mesitylene, and continue stirring to raise the temperature to 180°C. The salt-forming reaction starts, the water generated in the system azeotropes with mesitylene, cooling water begins to drip from the condenser tube, and the layers are separated in the water separator. After the upper layer of mesitylene turns from turbid to clear, reflux continues for 20 minutes In order to ensure the complete salt formation reaction, the salt formation stage is 1 hour, after the salt formation is completed, the temperature is raised to 21...

Embodiment 2

[0033] Same as Example 1, except that 3-fluoro-4-chlorobenzophenone replaces 3,4′-difluorobenzophenone, tetramethylbenzene replaces mesitylene, other conditions are the same.

[0034] The resulting PSU resin melt index MI = 16.0g / 10min (343.0°C, 2.16KG, 5 minutes);

[0035] MI=15.4g / 10min (343.0°C, 2.16KG, 30 minutes).

Embodiment 3

[0037] Same as Example 1, except that 3-chloro-4-fluorobenzophenone is substituted for 3,4'-difluorobenzophenone, other conditions are the same.

[0038]The resulting PPSU resin melt index MI = 16.0g / 10min (343.0°C, 2.16KG, 5 minutes);

[0039] MI=15.4g / 10min (343.0°C, 2.16KG, 30 minutes).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com