Quaternary phosphonium salt and application thereof

A technology of quaternary phosphorus salt and structural formula, which is applied in the field of quaternary phosphorus salt and its preparation, can solve the problems of complex preparation and post-treatment process, unfavorable environmental protection and sustainable development, uneconomical application, etc., and achieves strong catalytic activity and applicability, Improve the double bond retention rate, the effect of high double bond retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of alkylacrylamide: alkylacrylamide and iodomethane in weak base catalyst (conventional Na 2 CO 3 、K 2 CO 3 Under the action of inorganic salts), react at 30-50°C for 2-3 hours, filter, concentrate and dry.

[0033] For the detection method of the double bond retention rate in the embodiments, the double bond retention rate of the sample is tested with reference to GB / T 13892-1992, and the method introduced in the standard is the iodometric method.

[0034] For the detection method of the hydroxyl value in the examples, the hydroxyl value of the sample is tested with reference to GB / T 7387-2007, and the method introduced in the standard is the phthalic anhydride method.

[0035] The preparation of the catalyst of the present invention and its application in the synthesis of amide / imide polyether macromers will be described separately.

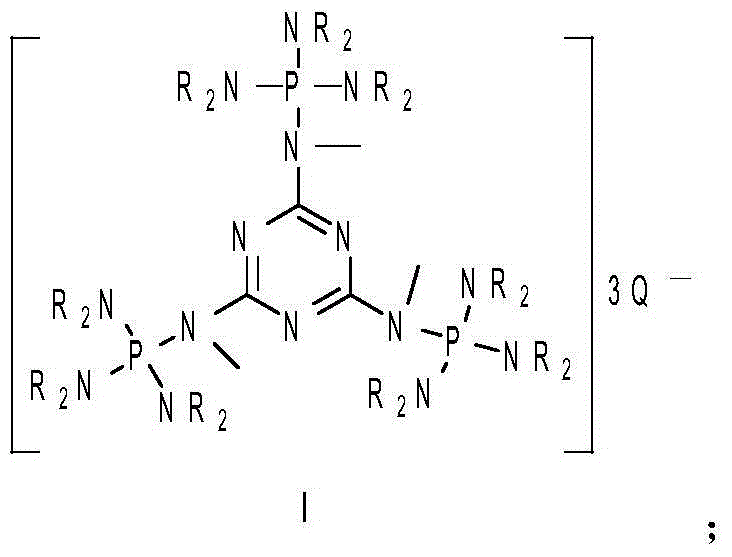

[0036] Preparation of quaternary phosphorus salt catalyst with melamine as the core.

Embodiment 1

[0038] Using dimethylamine and phosphorus pentachloride as raw materials to synthesize 3-dimethylaminophosphorus dichloride, and then react with melamine for condensation reaction, and then react with Me 2 SO 4 Methylation reaction occurs, and anion exchange reaction with sodium acetate, sodium tetrafluoroborate, etc. can also occur to generate the corresponding target product: melamine-based (3-dimethylamino) quaternary phosphonium compound. For specific synthesis methods, please refer to the article and Patents (US 6469218, EP 0791600A1, WO0190220A2, US2002183561A1, Jiangsu Chemical Industry, 2008, 36, 1-5; Fudan Journal (Natural Science Edition), 2013, 52, 39-43, etc.), the specific material ratio is as follows:

[0039]

[0040]

[0041] The product was recrystallized in a mixed solvent of methanol:ethyl acetate=10:1, and was obtained in the form of quaternary phosphorus salt, yield: 96%, black solid.

[0042] 1 H NMR (CDCl 3 ,25℃,TMS),δ=2.51(s,3H×18,-CH 3 ),2.32...

Embodiment 2

[0044] Using dimethylamine and phosphorus pentachloride as raw materials to synthesize 3-dimethylaminophosphorus dichloride, and then react with melamine for condensation reaction, and then react with Me 2 SO 4 Methylation reaction occurs, anion exchange reaction occurs with sodium tetrafluoroborate, and the corresponding target product is generated: melamine-based (3-dimethylamino) quaternary phosphonium compound, and the specific synthesis method can refer to articles and patents (US 6469218, EP 0791600A1, WO0190220A2, US2002183561A1, Jiangsu Chemical Industry, 2008, 36, 1-5; Fudan Journal (Natural Science Edition), 2013, 52, 39-43, etc.), the specific material ratio is as follows:

[0045]

[0046]

[0047] The product was recrystallized in a mixed solvent of methanol:ethyl acetate=10:1, and was obtained in the form of quaternary phosphorus salt, yield: 93%, black solid.

[0048] 1 H NMR (CDCl 3 ,25℃,TMS),δ=2.50(s,3H×18,-CH 3 ),2.33(s,3H×3,-CH 3 ),; elemental ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com