Cement production device and method

A cement production device and cement technology are applied in the field where flue gas desulfurization is required, which can solve the problems of environmental damage, high energy consumption, difficult treatment, etc., and achieve the effects of improving quality, ensuring high-efficiency operation, and ensuring sufficient saturation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

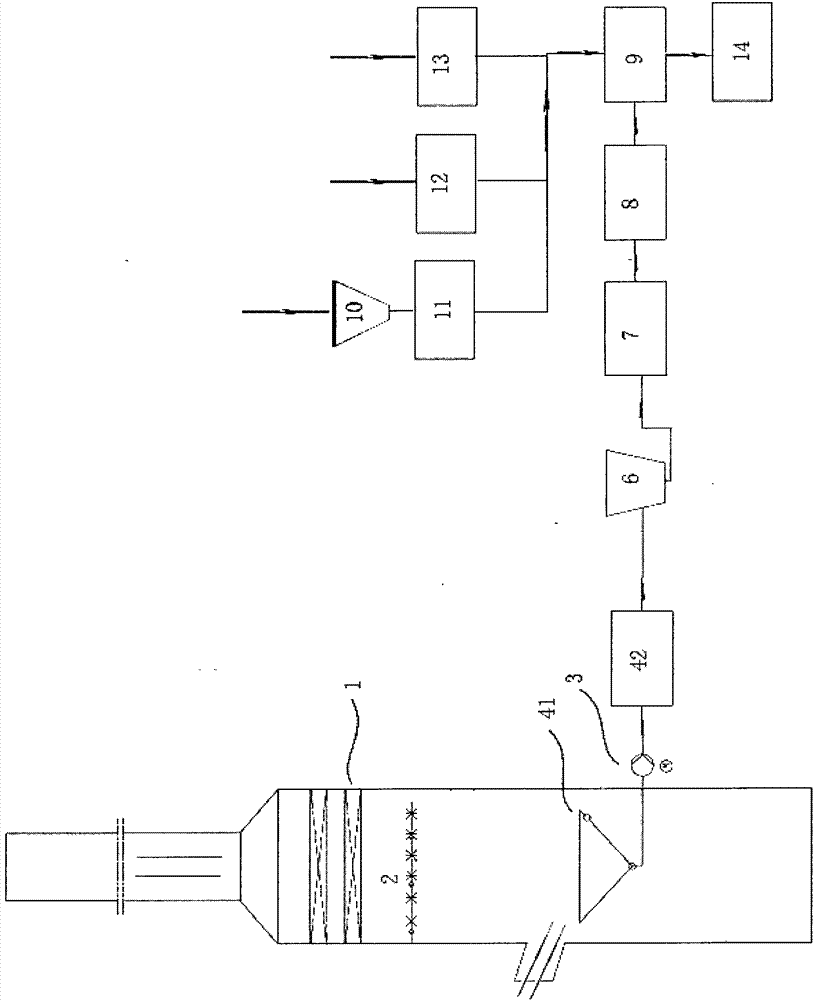

[0095] figure 1 Is the device schematic diagram of this embodiment. Add industrial tap water to the desulfurizing agent magnesium oxide powder to make desulfurizing agent slurry-magnesium hydroxide slurry, and pump it to the desulfurization tower 1 for absorbing sulfur dioxide in the flue gas in the sulfur dioxide absorption spray area.

[0096] Flue gas from sintering machines in steel mills (sulfur dioxide content is 2000mg / Nm 3 , adjusting the oxygen content to be 18vt%) enters the interior of the desulfurization tower 1 from the bottom of the desulfurization tower 1 . During the rising process of the flue gas, it contacts with the sulfur dioxide absorbing and spraying area 2, and the flue gas is discharged from the top of the desulfurization tower 1. The sulfur dioxide absorbing spray zone 2 sprays desulfurizer slurry to absorb sulfur dioxide in the flue gas.

[0097] Magnesium sulfate-containing absorption product formed by desulfurizer slurry after absorbing sulfur di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com