Front filter

A technology of pre-filter and filter interface, applied in the direction of filtration treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve problems such as uneven filtration accuracy, filter pollution, secondary pollution, etc., and achieve convenience Cleaning and maintenance, recovery of filtration performance, good self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

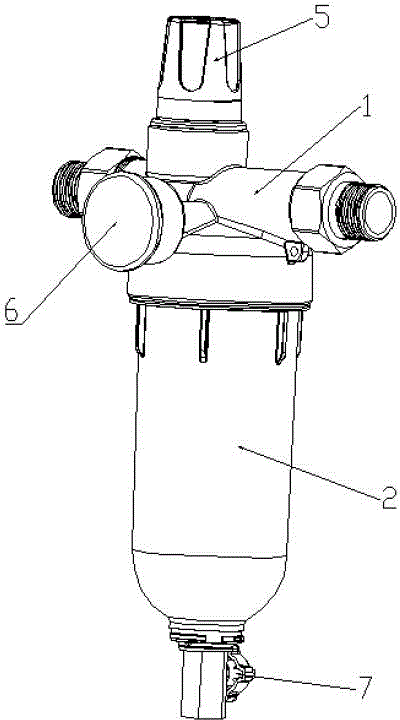

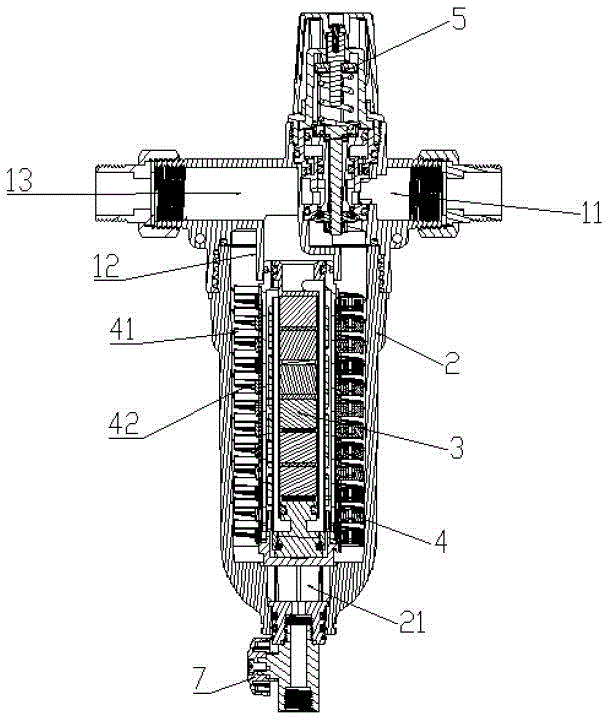

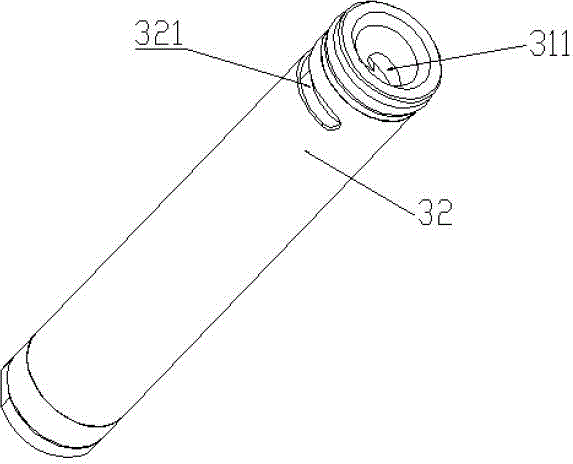

[0036] Such as figure 1 , 2 As shown, the pre-filter proposed by the present invention includes: an upper cover 1 , a cylinder 2 fixed at the lower end of the upper cover 1 , a magnetized filter element 3 and a spiral filter element 4 arranged in the cylinder body 2 . The bottom of the upper cover 1 is open and there are separated water inlets and outlets on both sides. The inner inlet of the water outlet 11 extends downward to form a filter interface 12. The upper end of the cylinder 2 is open, and the upper end of the cylinder 2 is connected to the bottom of the upper cover 1 The end opening is sealed and connected. The magnetized filter element 3 is arranged in the center of the cylinder body 2. The spiral filter element 4 includes a spiral frame 41 and at least one layer of spiral filter screen 42 covered along its spiral surface. The spiral frame 41 is arranged in the cylinder body 2 and surrounds it. In the magnetized filter element 3 , the outer edge of the spiral fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com