Method for removing metal thallium in wastewater

A waste water and metal technology, applied in chemical instruments and methods, water pollutants, multi-stage water treatment, etc., can solve the problems of investment cost and lack of convenient operation and maintenance, and achieve the effect of convenient operation cost and convenient operation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

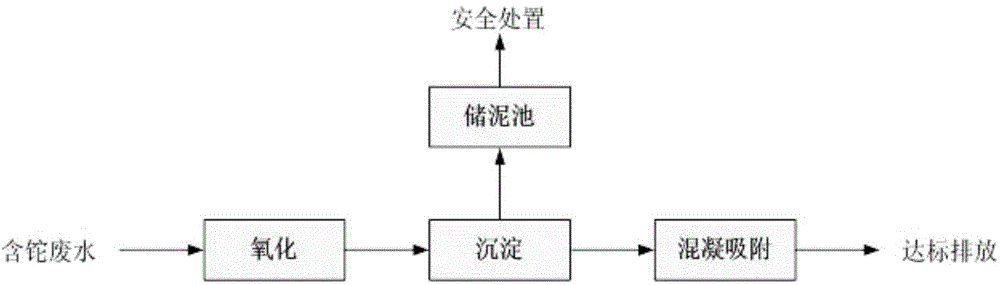

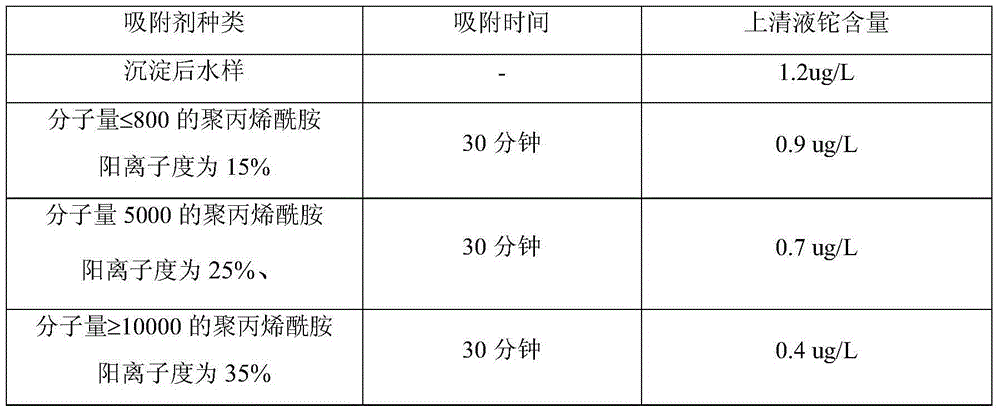

Method used

Image

Examples

Embodiment Construction

[0017] The present invention can be further clearly understood through the specific examples of the present invention given below, but they are not intended to limit the present invention. Parts not described in detail in the specific embodiments are obtained by using prior art, known technical means and industry standards.

[0018] Unless otherwise stated, the percentages used in the present invention are all percentages by weight.

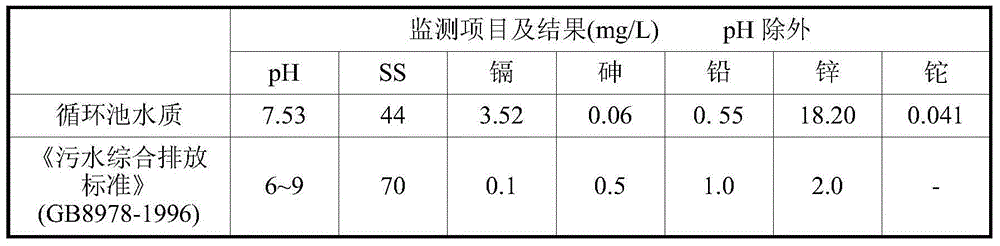

[0019] The method of the invention is adopted to treat the slag flushing circulating water (thallium-containing waste water) of Xiangxiang Jialian Zinc Industry Co., Ltd.

[0020] Xiangxiang Jialian Zinc Industry Co., Ltd. belongs to the non-ferrous metal smelting industry, mainly smelting zinc oxide; the main raw materials for production come from blast furnace gas mud and zinc smelting water-quenching slag. The production process: firstly, the gas mud, water-quenching slag, Combustion coal, etc. are crushed and then mixed in proportion and tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com