Method for producing aluminum oxide by treating low-grade bauxite with ammonia-alkali combination method

A technology of low-grade bauxite and combined method, which is applied in the direction of alumina/hydroxide, etc., can solve the problems of low resource utilization, high energy consumption, and low recovery rate, and improve the comprehensive utilization of resources and energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

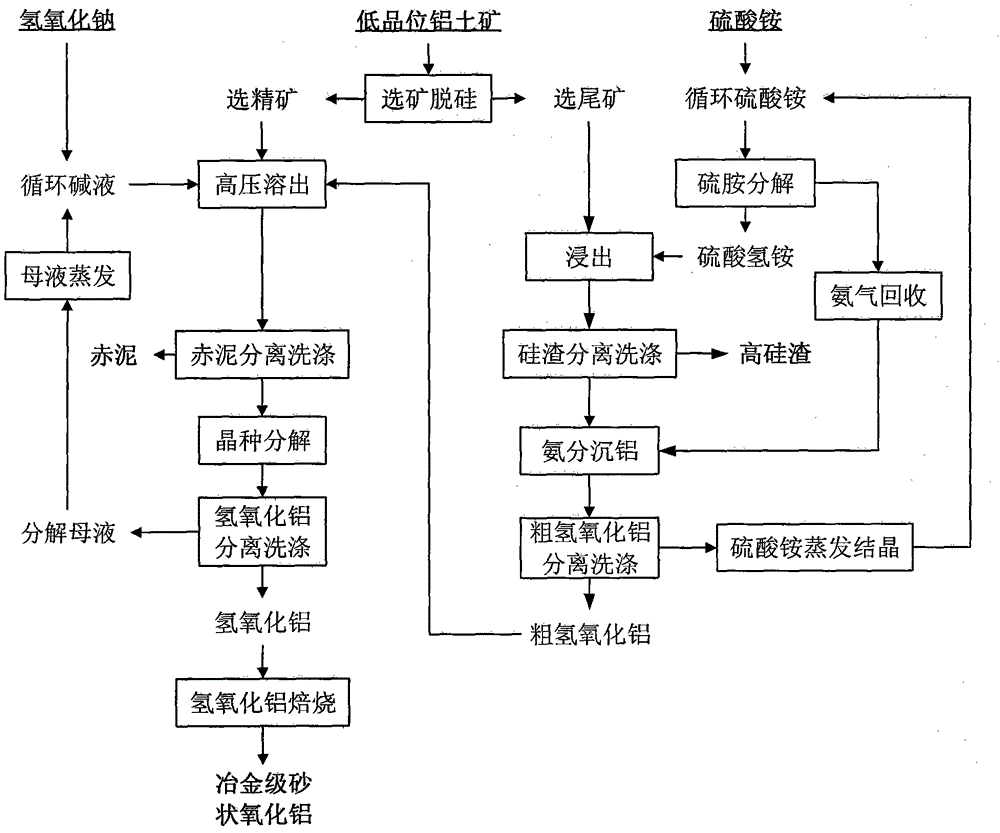

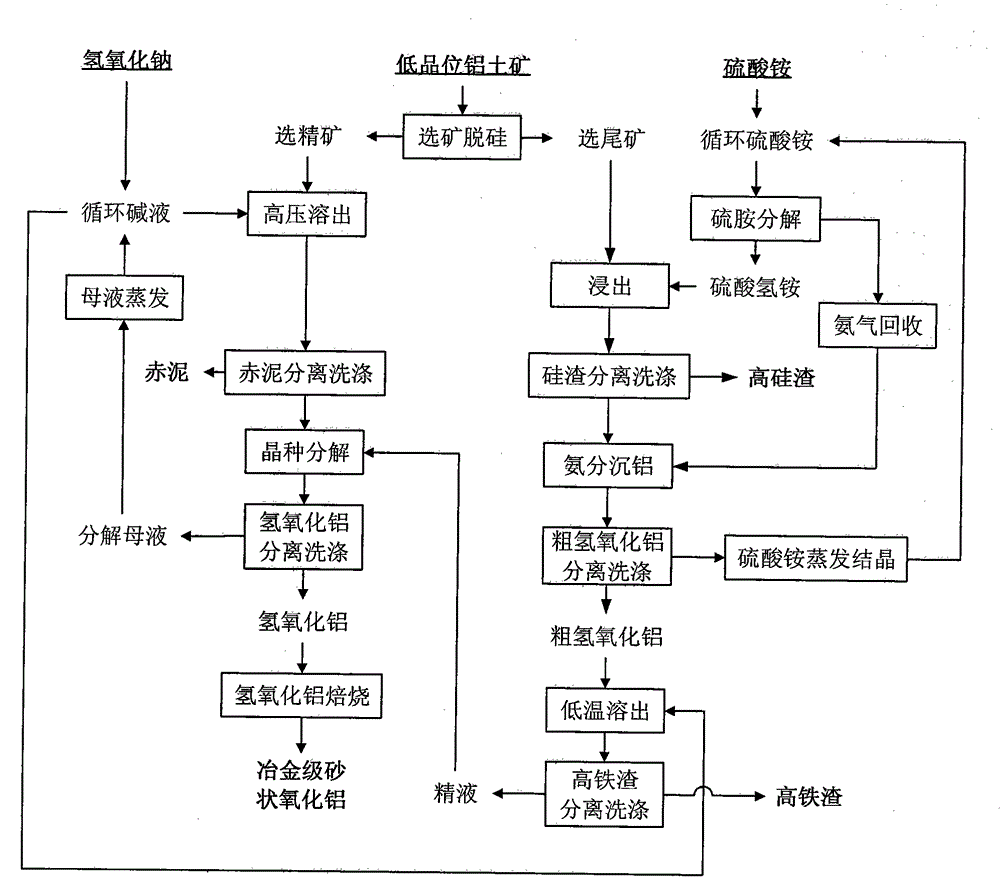

Method used

Image

Examples

Embodiment 1

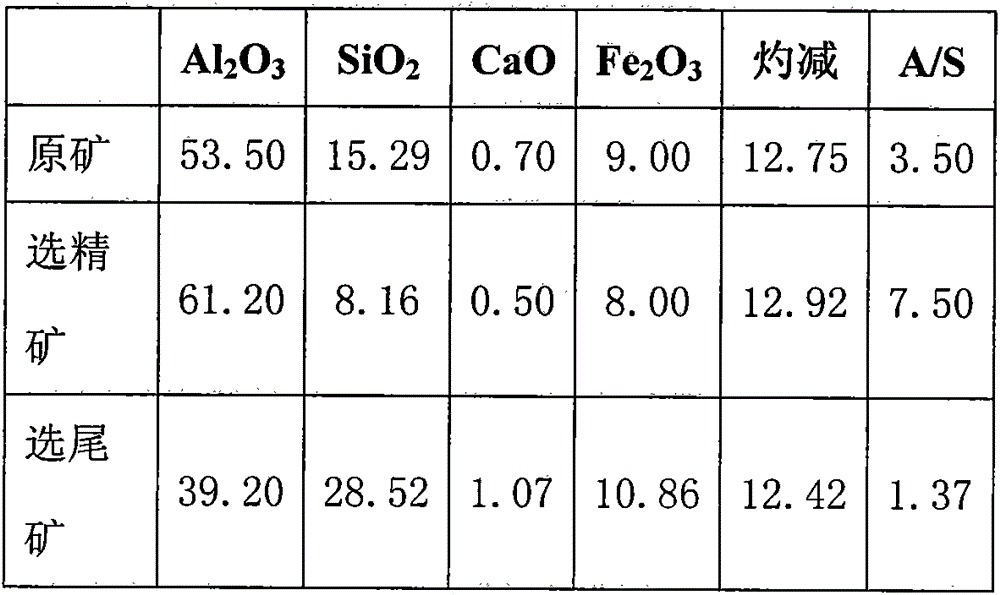

[0028] The composition of low-grade bauxite, concentrated ore and tailings is shown in the table below, and the ore composition of other embodiments is the same as this table.

[0029]

[0030] 1000g of low-grade bauxite is desiliconized by positive flotation to obtain about 650g of concentrate and 350g of tailings. The concentrate is processed according to steps A1-A5, and the tailings are processed according to steps B1-B5.

[0031] A1. High-pressure stripping: After the concentrated ore is mixed with the circulating lye, it is stripped at 265°C under high pressure (naturally formed at a pressure of 265°C, the same below) for 60 minutes;

[0032] A2. Separation and washing of red mud: After the dissolution, the slurry is separated and washed with red mud;

[0033] A3. Decomposition of seed crystals: After the semen is cooled to 65°C, add seed crystals to decompose;

[0034] A4. Separation and washing: after separation and washing, aluminum hydroxide and decomposed mother...

Embodiment 2

[0043] 1000g of low-grade bauxite is desiliconized by reverse flotation to obtain about 650g of concentrate and 350g of tailings. The concentrate is processed according to steps A1-A5, and the tailings are processed according to steps B1-B5.

[0044] A1. High-pressure stripping: After the concentrated ore is mixed with circulating lye, it is stripped at 290°C for 10 minutes under high pressure;

[0045] A2. Separation and washing of red mud: After the dissolution, the slurry is separated and washed with red mud;

[0046] A3. Decomposition of seed crystals: After the semen is cooled to 65°C, add seed crystals to decompose;

[0047] A4. Separation and washing: after separation and washing, aluminum hydroxide and decomposed mother liquor are obtained; the decomposed mother liquor is evaporated and prepared to obtain circulating lye and sent to step A1 for recycling;

[0048] A5. Roasting of aluminum hydroxide: aluminum hydroxide is roasted at 1050°C to obtain metallurgical grade...

Embodiment 3

[0056] 1000g of low-grade bauxite is desiliconized by positive flotation to obtain about 650g of concentrate and 350g of tailings. The concentrate is processed according to steps A1-A5, and the tailings are processed according to steps B1-B5.

[0057] A1. High-pressure stripping: After the concentrated ore is mixed with circulating lye, it is stripped at 300°C for 5 minutes under high pressure;

[0058] A2. Separation and washing of red mud: After the dissolution, the slurry is separated and washed with red mud;

[0059] A3. Decomposition of seed crystals: After the semen is cooled to 65°C, add seed crystals to decompose;

[0060] A4. Separation and washing: after separation and washing, aluminum hydroxide and decomposed mother liquor are obtained; the decomposed mother liquor is evaporated and prepared to obtain circulating lye and sent to step A1 for recycling;

[0061] A5. Roasting of aluminum hydroxide: aluminum hydroxide is roasted at 1050°C to obtain metallurgical grade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com