Labyrinth type self-locking device of winder

A self-locking device and labyrinth technology, which is applied in the field of labyrinth self-locking devices, can solve problems such as troublesome manufacturing and installation, complex structure, broken teeth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

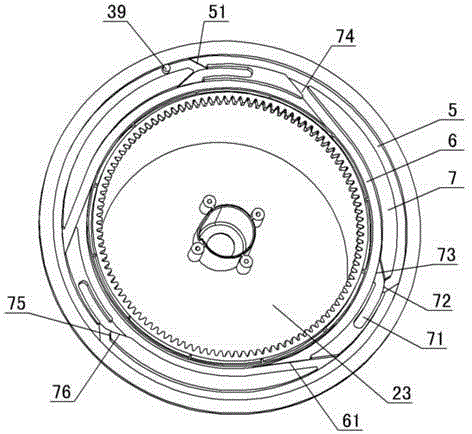

[0014] The invention relates to a labyrinth self-locking device of a hose reel, such as figure 1 — Figure 7As shown, it includes the right cover 21 and the right reel 23 of the hose reel. It is characterized in that: the inner wall of the right cover 21 limits the limiting cavity 29 and the fixing column 30, and the screw hole is opened in the fixing column. A stop card 31 is arranged in the cavity, and the stop card 31 includes a body 32. A circular groove 33 is formed on one end of the body, and a perforation 34 is opened in the circular groove. Limit washer 35, screw 36 passes through limit washer 35 and threadedly fits with the screw hole of fixed post 30, is shaped on elastic plate 37 and pressing plate 38 at the other end of body 32, and is shaped on guide post on the pressing plate 39. A labyrinth guide ring groove is formed on one side of the right reel 23. The labyrinth guide ring groove matches the guide column. The labyrinth guide ring groove includes the outer ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com