Burst wine cap with novel burst ring

A wine cap, a new type of technology, applied in the direction of locking equipment, etc., can solve the problems of irregular appearance of the burst ring, low efficiency, waste of hot stamping paper, etc., and achieve the effect of facilitating production and assembly, reducing the outer diameter and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

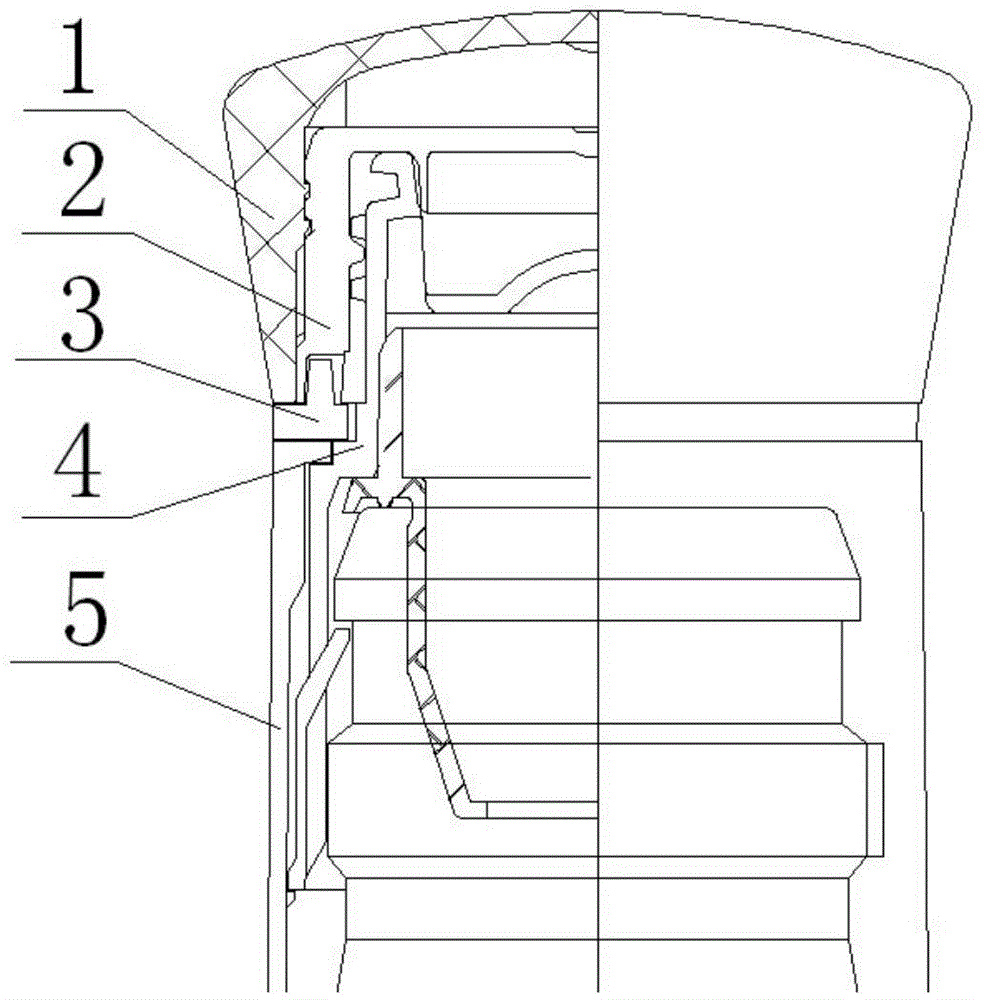

[0019] Such as image 3 , a bursting wine cap with a novel bursting ring, comprising a crown-shaped cap 1, a bursting inner cap 2, a bursting ring 3, a wine pourer 4, and a jacket 5, and the outer diameter of the bursting ring is 0.1mm~ 0.8mm, preferably 0.6mm. After the assembly of the wine cap, because there is a gap between the burst ring 3 and the wine pourer 4, and 0.1mm~0.8mm is used as the deformation space between the burst ring 3 and the wine pourer 4, the burst ring 3 after assembly Able to line up just right with the jacket 5, giving the popped wine cap a flat look.

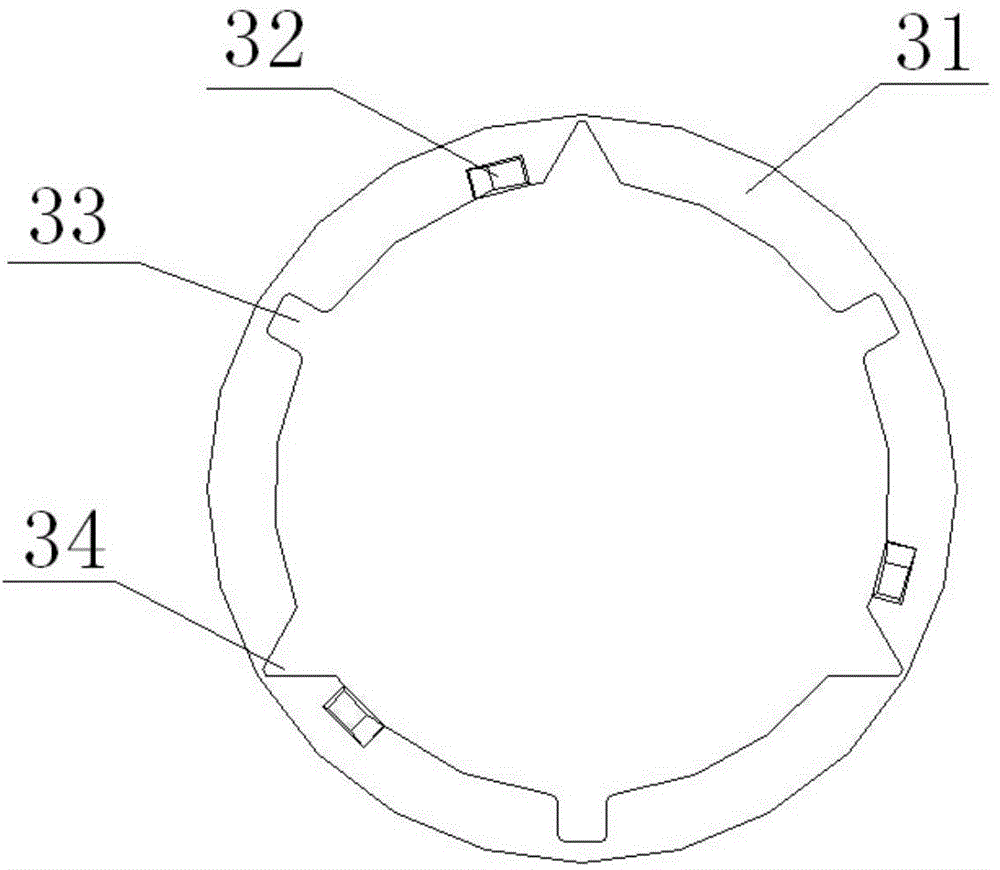

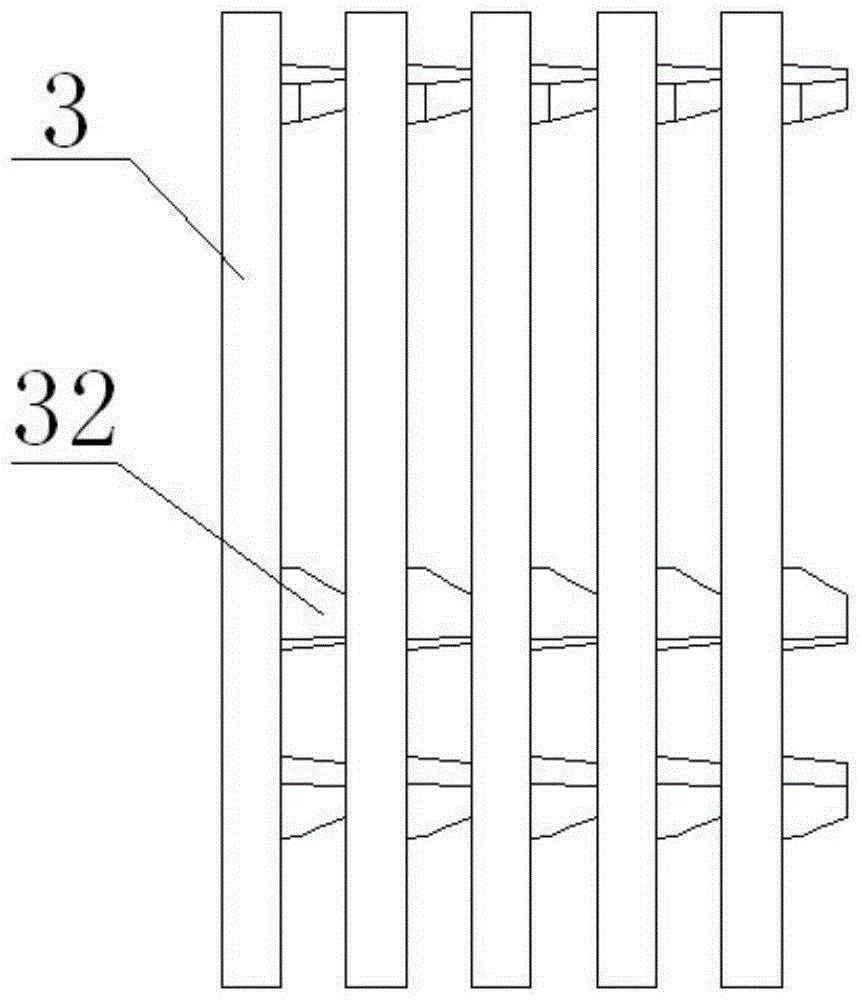

[0020] Such as Figure 4 , Figure 5 , a bursting wine cap with a novel bursting ring, the bursting ring 3 includes a ring body 31, a protrusion 32, a fixing notch 33 and a stress concentration notch 34, and the stress concentration notch 34 includes a breakable notch 341 and stress spines Claw 342. The width of the protrusion 32 is not greater than the width of the stress concentration notch 34 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com