Labeling Machine

A labeling machine and labeling technology, which is applied in the direction of labeling machines, labels, packaging, etc., can solve the problems of labeling machines with complex structures and large footprints, and achieve small footprints, short machine adjustment time, and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

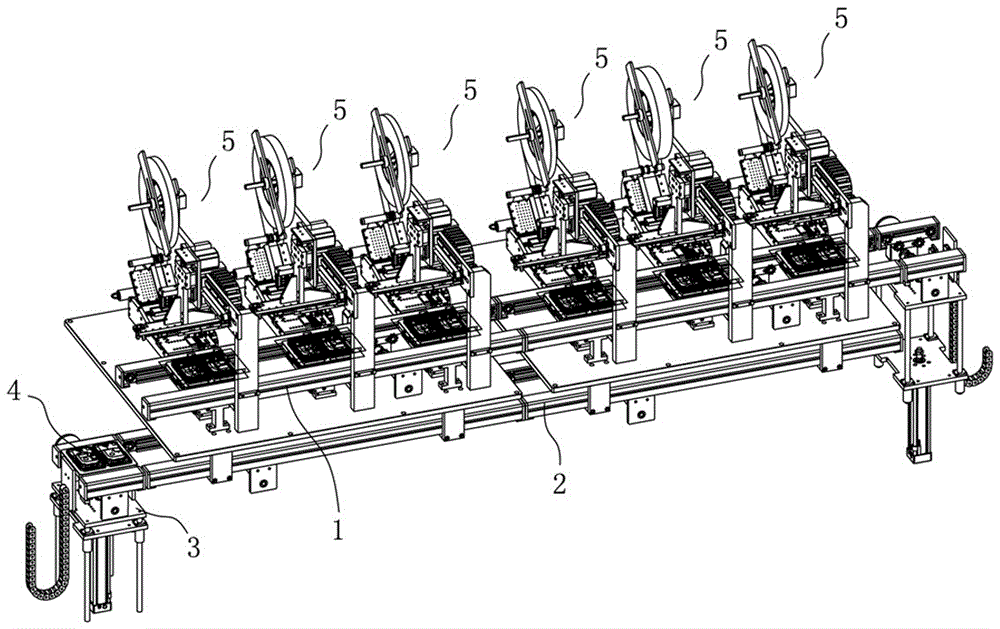

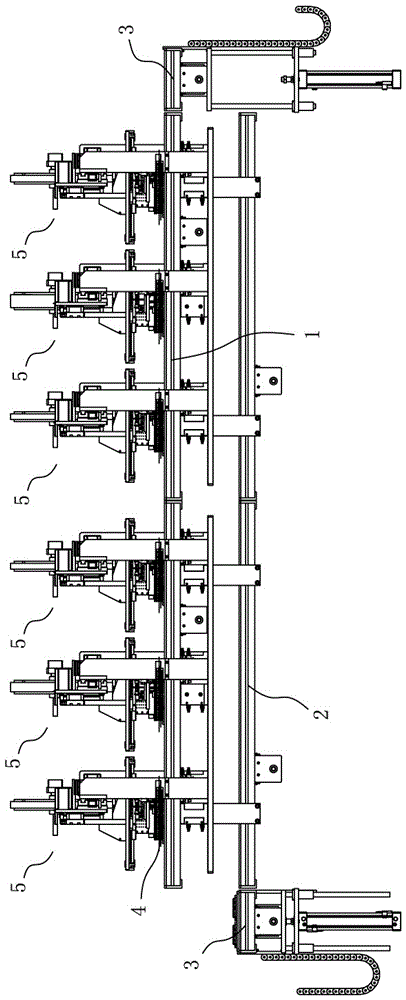

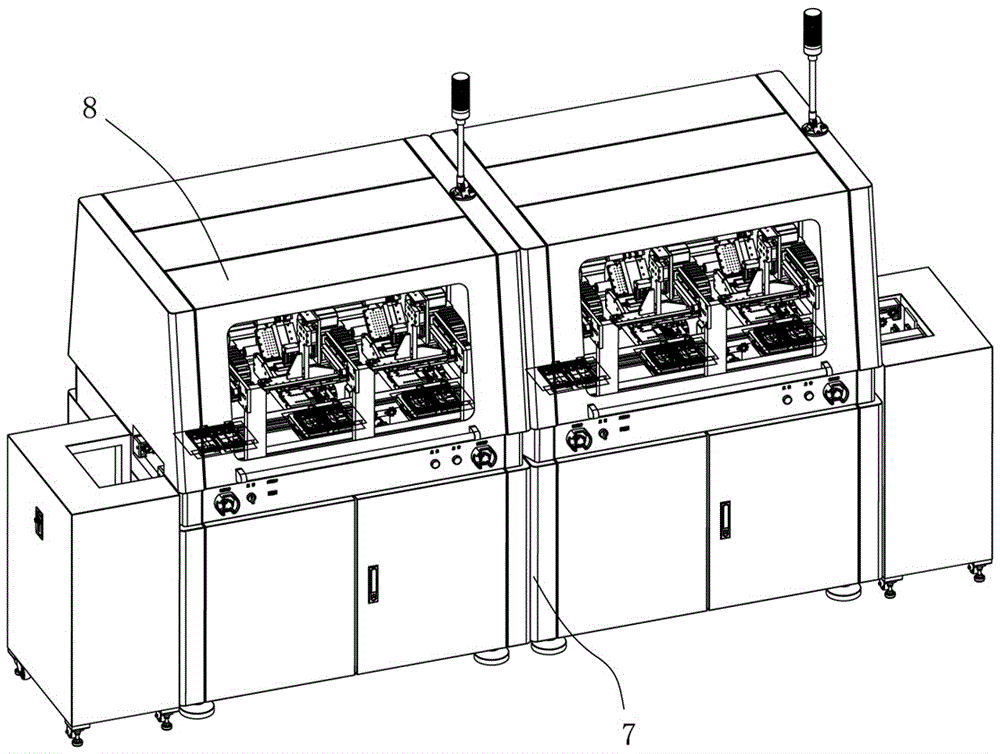

[0025] Example: see Figure 1 to Figure 10 , a labeling machine, including a sticking production line 1, a fixture return line 2, the sticking production line 1 and the fixture return line 2 are arranged in two layers and are respectively provided with lifting tables 3 at both ends for transfer and transportation The fixture 4 is provided with more than one labeling station along the sticking production line 1, and a labeling device 5 is installed at each station, and each labeling device on the production line cooperates to complete the labeling operation on the mobile phone shell. A jig positioning device 6 is provided below the labeling station, and the present invention also includes a frame 7 and an outer machine cover 8 . The jig 4 of the present invention is provided with at least one product fixing groove 41, such as Figure 9 , There are two product grooves on the jig to cooperate with double suction heads. The jig positioning device 6 of the present invention inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com