Printable double-faced heat sealing film, preparation method and application thereof

A film and double-sided technology, applied in the field of film production and processing, can solve the problem that PE film cannot have both printability and double-sided heat sealability, and achieve good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

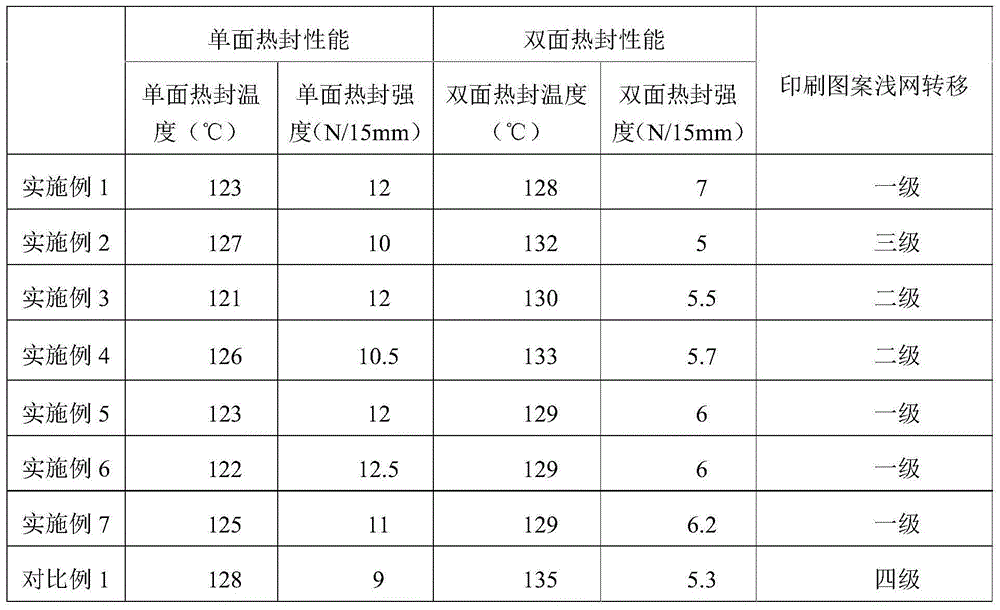

Examples

preparation example Construction

[0030] In addition, the present invention also provides a method for preparing a printable double-sided heat-sealing film, which includes the following steps: co-extruding and blow molding the raw materials of the outer layer, the middle layer and the inner layer. Specifically, the preparation process is as follows:

[0031] Step 1, mixing materials, respectively stirring the raw materials of the outer layer, the middle layer and the inner layer into a mixed material according to the consumption ratio of the raw materials of each layer;

[0032] Step 2, batching, batching according to the weight percentage between layers according to the compounding of each layer of the outer layer, the middle layer and the inner layer;

[0033] Step 3: Co-extrude the blown film, and use a blown film machine for blow molding to obtain the above-mentioned printable double-sided heat-sealable film.

[0034] The specific preparation process may include a mixing process, a feeding process, a plas...

Embodiment 1

[0038] (1) Ingredients:

[0039] Raw materials and weight percentages for the outer layer: 60% LLDPE-7042; 20% LDPE-2420H; and 20% MLLDPE-5100G;

[0040] Raw materials and weight percentages for the middle layer: 75% LLDPE-7042; 25% MDPE-2230;

[0041] Raw materials and weight percentages for the inner layer: 48% LLDPE-0220KJ; 24% LDPE-2426H; 24% MLLDPE-5100G; 2% anti-blocking agent EAZ-10; and 2% slip agent ESQ-4 ;

[0042] Among them, the raw materials for the outer layer, the raw materials for the middle layer and the raw materials for the inner layer account for 25%, 50% and 25% of the total mass of the raw materials respectively.

[0043] (2) Blow molding:

[0044] The above proportioned materials are processed in multi-layer co-extrusion blow molding equipment, including the following processes: mixing process, feeding process, plasticizing extrusion process, inflation traction process, air ring cooling process, herringbone splint process, traction Roller pulling pro...

Embodiment 2

[0046] (1) Ingredients:

[0047] Raw materials and weight percentages for the outer layer: 50% LLDPE-7042; 25% LDPE-2420H; and 25% SP1520;

[0048] Raw materials and weight percentages for the middle layer: 70% of 201XV; 30% of MDPE-2230;

[0049] Raw materials and weight percentages for the inner layer: 40% LLDPE-0220KJ; 30% 2426D; 27% SP1520; 2% anti-blocking agent EAZ-10; and 1% slip agent ESQ-4;

[0050] Among them, the raw materials for the outer layer, the raw materials for the middle layer and the raw materials for the inner layer account for 25%, 50% and 25% of the total mass of the raw materials respectively.

[0051] (2) Blow molding:

[0052] The above proportioned materials are processed in multi-layer co-extrusion blow molding equipment, including the following processes: mixing process, feeding process, plasticizing extrusion process, inflation traction process, air ring cooling process, herringbone splint process, traction Roller pulling process, corona treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com