Wide-gap square butt joint welding technology and welding structure

A welding process and flat butt joint technology, which is applied in the field of single-sided flat butt joint automatic welding, can solve the problems of segregation, inclusions, weld cracks and other problems of the bottom weld bead, and achieve beautiful and beautiful weld shape, prevent impact toughness reduction, crystal Small and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

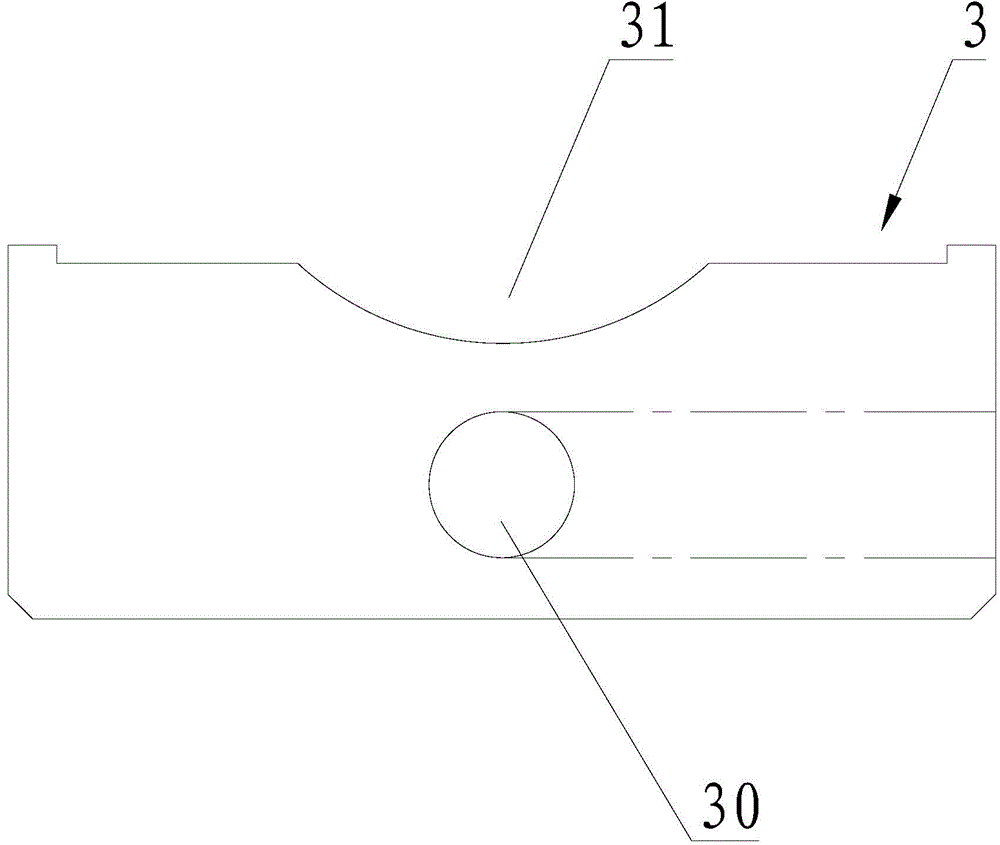

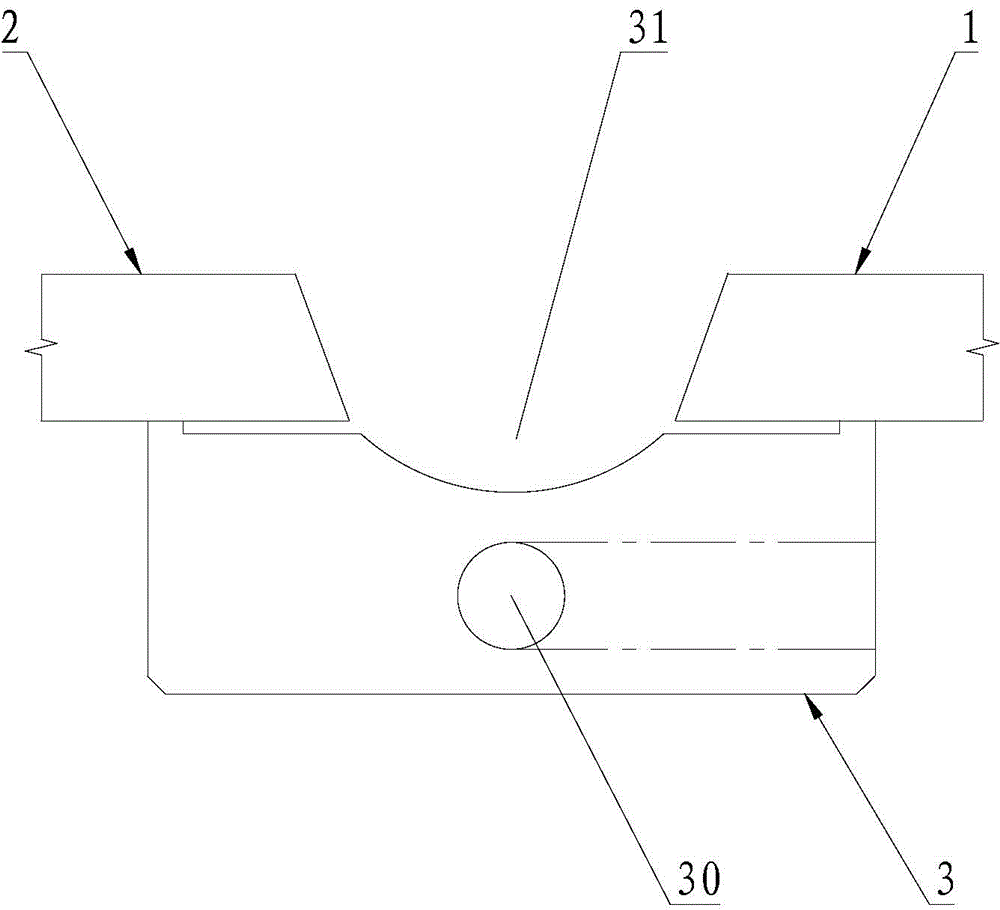

[0020] The most critical idea of the present invention is: use copper liner instead of ceramic liner, there is no problem of inclusions caused by ceramics being melted and stirred; the copper liner is cooled during bottom welding, so that the weld can be rapidly cooled and formed while preventing welding The joint produces overheated tissue, which effectively reduces the degree of segregation and improves the mechanical properties of the welded joint; the solid welding wire is used for root welding, which is not easy to produce weld cracks and thorns. The use of backing flux ensures weld bead formation.

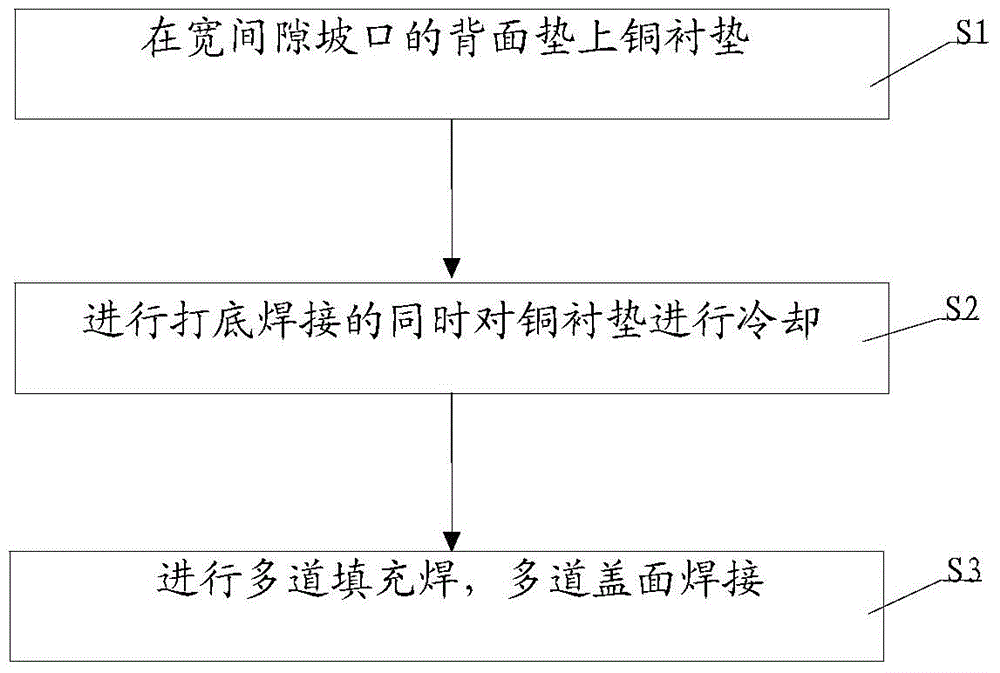

[0021] Specifically, please refer to Figure 1 to Figure 5 Shown, wide gap flat butt welding process of the present invention comprises:

[0022] S1. A cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com