A kind of rolling method of ta7 titanium alloy plate

A technology of titanium alloy and rolling direction, which is applied in metal rolling and other directions, can solve the problems of narrow processing window, slag falling, hurting people, etc., and achieve the effect of ensuring the billet rolling temperature, reducing the amount of grinding, and reducing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment TA7

[0031] The rolling method of present embodiment TA7 titanium alloy plate comprises the following steps:

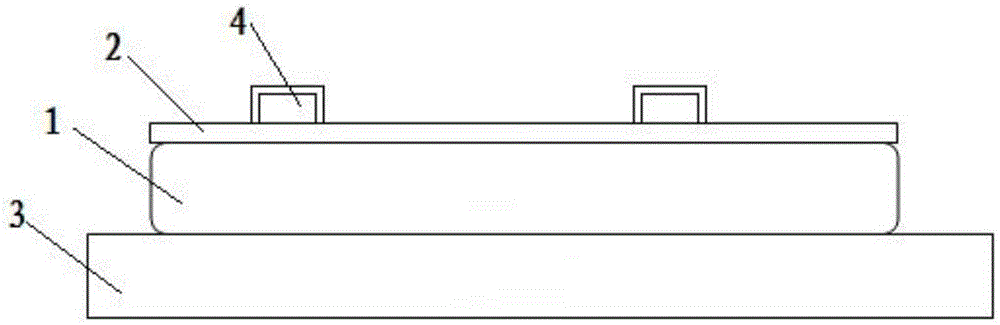

[0032] Step 1, placing the TA7 titanium alloy slab 1 between the upper cladding material 2 and the lower cladding material 3 to obtain a composite plate (such as figure 1 shown), and then the composite plate is kept at a temperature of 1150° C. for 4 hours for the first heat treatment; the thickness of the TA7 titanium alloy slab 1 is 180 mm, the width is 1100 mm, and the length is 1300 mm; the above The thickness of the covering material 2 is 4mm, the width is 1110mm, and the length is 1310mm; the thickness of the lower covering material 3 is 25mm, the width is 1200mm, and the length is 1400mm; the upper surface of the upper covering material 2 is welded with two pull rings 4; The upper covering material 2 and the lower covering material 3 are both 304 stainless steel plates;

[0033]Step 2, separating the upper cladding material 2 and the lower cladding material 3 after...

Embodiment 2

[0042] The rolling method of present embodiment TA7 titanium alloy plate comprises the following steps:

[0043] Step 1, placing the TA7 titanium alloy slab 1 between the upper cladding material 2 and the lower cladding material 3 to obtain a composite plate (such as figure 1 shown), and then the composite plate is kept at a temperature of 1130° C. for 4.5 hours for the first heat treatment; the thickness of the TA7 titanium alloy slab 1 is 150 mm, the width is 900 mm, and the length is 1200 mm; the The thickness of the overlying material 2 is 3mm, the width is 905mm, and the length is 1205mm; the thickness of the underlying material 3 is 20mm, the width is 920mm, and the length is 1220mm; the upper surface of the overlying material 2 is welded with two Ring 4; the upper covering material 2 and the lower covering material 3 are 304 stainless steel plates;

[0044] Step 2, separating the upper cladding material 2 and the lower cladding material 3 after the first heat treatment...

Embodiment 3

[0053] The rolling method of present embodiment TA7 titanium alloy plate comprises the following steps:

[0054] Step 1, placing the TA7 titanium alloy slab 1 between the upper cladding material 2 and the lower cladding material 3 to obtain a composite plate (such as figure 1 shown), and then the composite plate is kept at a temperature of 1140° C. for 3 hours for the first heat treatment; the thickness of the TA7 titanium alloy slab 1 is 130 mm, the width is 850 mm, and the length is 1300 mm; the above The thickness of the covering material 2 is 3mm, the width is 850mm, and the length is 1300mm; the thickness of the lower covering material 3 is 30mm, the width is 910mm, and the length is 1360mm; the upper surface of the upper covering material 2 is welded with two pull rings 4; The upper covering material 2 and the lower covering material 3 are both 304 stainless steel plates;

[0055]Step 2. Separate the upper cladding material 2 and the lower cladding material 3 after the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com