A dual-cylinder electro-hydraulic servo synchronous vibration cutting device and method

A synchronous excitation, double-cylinder electro-hydraulic technology, applied in servo motors, fluid pressure actuators, fluids using vibration, etc., can solve problems such as insufficient excitation power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

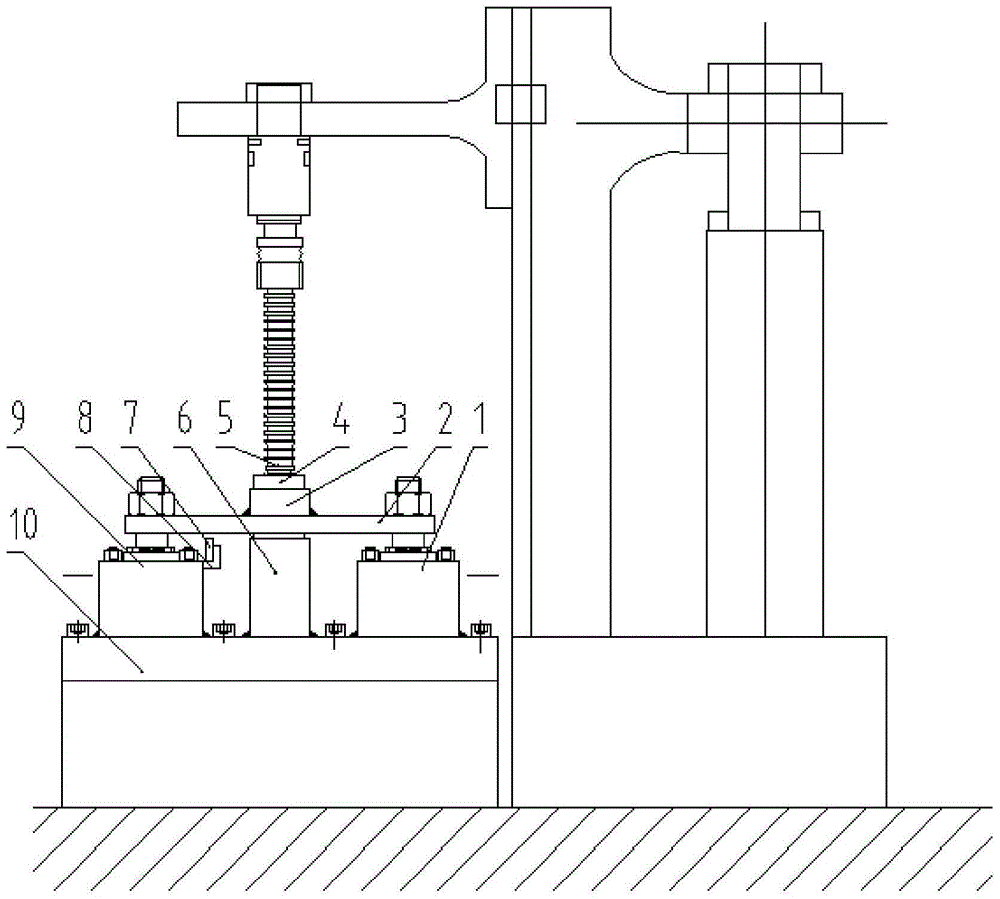

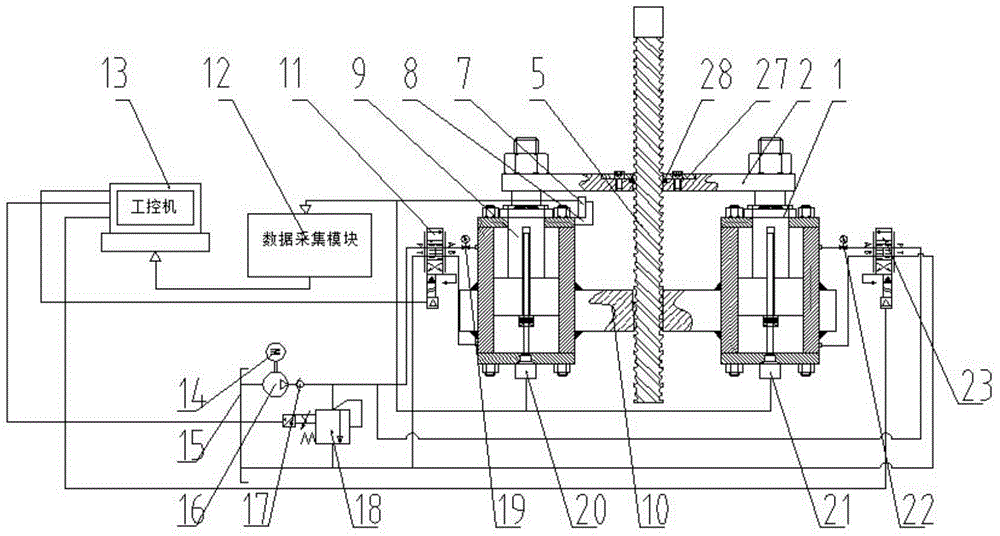

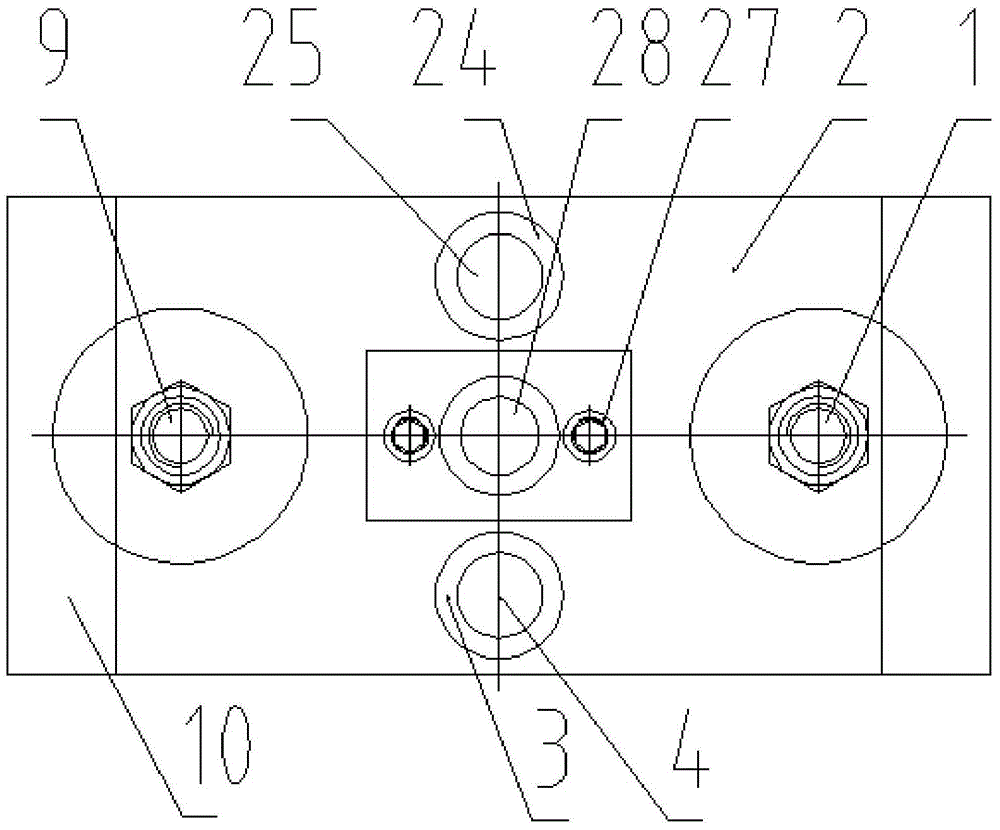

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] like figure 1 , figure 2 , image 3 , Figure 4As shown, a double-cylinder electro-hydraulic servo synchronous vibration excitation device for high-power cutting includes a first vibration hydraulic cylinder 1, a worktable 2, a first guide post guide sleeve 3, a first guide post 4, and a first guide post fixed Set 6, eddy current sensor 7, sensor bracket 8, second vibration hydraulic cylinder 9, base 10, first servo valve 11, data acquisition module 12, industrial computer 13, motor 14, oil source 15, hydraulic pump 16, one-way Valve 17, overflow valve 18, first pressure flow sensor 19, first piston displacement sensor 20, second piston displacement sensor 21, second pressure flow sensor 22, second servo valve 23, second guide column guide sleeve 24, The second guide post 25 , the second guide post fixing sleeve 26 and the clamp 27 .

[0026] The first vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com