Preparation method and application of alpha-manganese oxide supported iron-samarium catalyst

A technology of catalyst and manganese oxide, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of high reaction temperature for complete catalytic elimination of benzene series

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

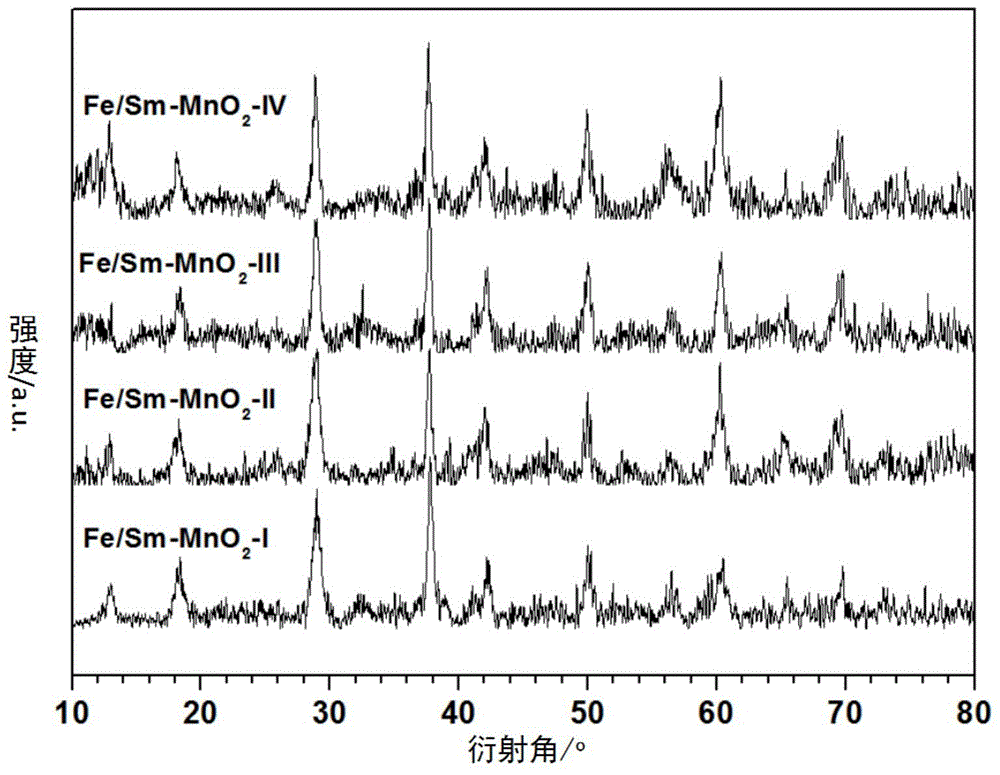

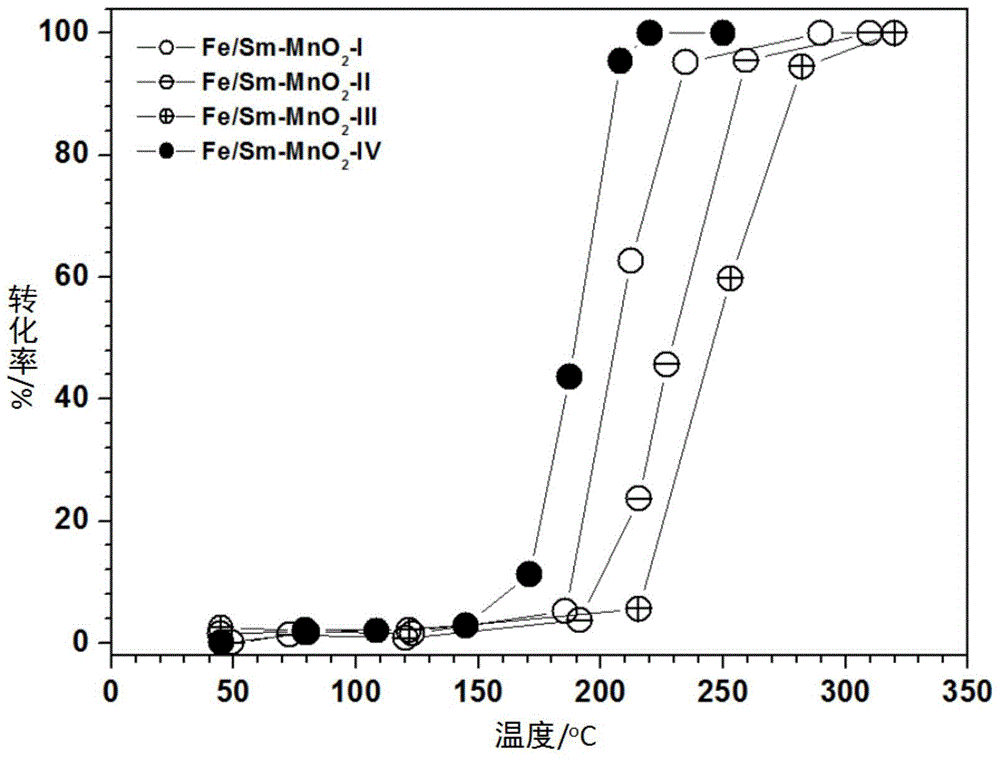

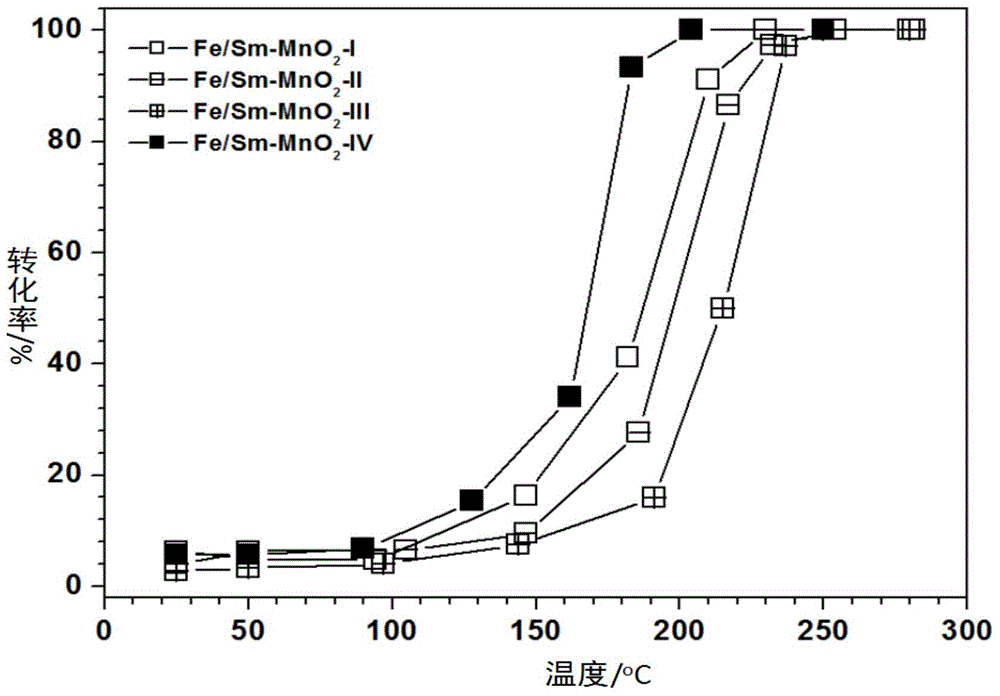

Embodiment 1

[0017] (1) the preparation method of above-mentioned catalyst provided by the present invention, comprises the steps:

[0018] Mix a certain amount of NaOH and citric acid into distilled water to form a buffer solution, wherein NaOH / citric acid is mixed in a molar ratio=1.02 to form a buffer solution, adjust the pH to 3.00, and then add 0.01g of Sm(NO 3 ) 3 .6H 2 O and 0.50gFe(NO 3 ) 3 .9H 2 O was dissolved in the above 40ml citric acid buffer solution. The above buffer solution containing metal salts was added to 24ml with a concentration of 1.0mol / L MnSO 4 solution, mix well. Then 120ml concentration of 0.1mol / L KMnO 4 The solution was dropped into the above mixed solution, in which KMnO 4 / MnSO 4 (molar ratio) = 0.5, stirred for 2 hours, sealed and aged for 12 hours, refluxed at 80°C for 20 hours, rotary steamed for 3 hours until powdery, rinsed with deionized water until neutral, dried at 100°C for 10 hours to obtain a black precursor body, and then ground into p...

Embodiment 2

[0021] (1) the preparation method of above-mentioned catalyst provided by the present invention, comprises the steps:

[0022] Mix a certain amount of NaOH and citric acid into distilled water to form a buffer solution, wherein NaOH / citric acid is mixed in a molar ratio=1.15 to form a buffer solution, adjust the pH between 4.00, and then add 0.03g of Sm(NO 3 )3 .6H 2 O and 1.50g Fe(NO 3 ) 3 .9H 2 O was dissolved in the above 40ml citric acid buffer solution. 0.5g of polyvinyl alcohol PVA (molecular formula (C 2 h 4 O) n , molecular weight 20000) dissolved in 33.3ml concentration is 1.2mol / L MnSO 4 In the solution, add the above buffer solution containing metal salts into this solution, and mix well. Then 140ml concentration of 0.2mol / L KMnO 4 The solution was dropped into the above mixed solution, in which KMnO 4 / MnSO 4 (molar ratio) = 0.7, stirred for 3 hours, sealed and aged for 12 hours, refluxed at 90°C for 22 hours, rotary steamed for 3 hours until powdered, r...

Embodiment 3

[0025] (1) the preparation method of above-mentioned catalyst provided by the present invention, comprises the steps:

[0026] Mix a certain amount of NaOH and citric acid into distilled water to form a buffer solution, wherein NaOH / citric acid is mixed in a molar ratio = 1.35 to form a buffer solution, adjust the pH to about 4.50, and then add 0.04g of Sm(NO 3 ) 3 .6H 2 O and 3.00g Fe(NO 3 ) 3 .9H 2 O was dissolved in the above 40ml citric acid buffer solution. 1.0g of polyvinyl alcohol PVA (molecular formula (C 2 h 4 O) n , molecular weight 20000) dissolved in 37.5ml concentration is 1.5mol / L MnSO 4 In the solution, add the above buffer solution containing metal salts into this solution, and mix well. Then 150ml concentration of 0.30mol / L KMnO 4 The solution was dropped into the above mixed solution, in which KMnO 4 / MnSO 4 (molar ratio) = 0.8, stirred for 4 hours, sealed and aged for 12 hours, refluxed at 110°C for 24 hours, rotary steamed for 4 hours until powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com